73

Group 40: PID Control

The PID Control Macro allows the ACS140 to take a reference signal

(setpoint) and an actual signal (feedback), and automatically adjust the speed

of the drive to match the actual signal to the reference. Figure 26 on page 96

(APPENDIX) shows the connections of internal signals when the PID Control

macro is selected.

Code Description

4001 PID GAIN

This parameter defines the gain of the PID Controller. The setting range is

0.1... 100. If you select 1, a 10 % change in error value causes the PID

Controller output to change by 10 %.

* Limited by parameter 2008

MAXIMUM FREQ.

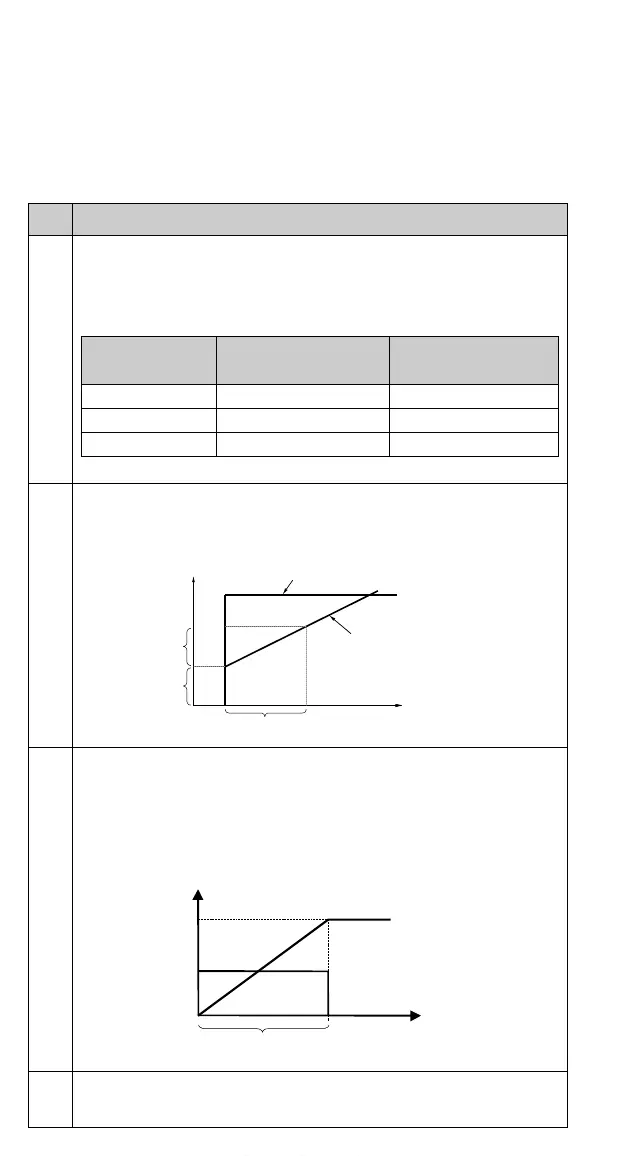

4002 PID INTEG TIME

PID controller integration time. Defined as the time in which the maximum

output is achieved if a constant error value exists and the gain is 1. Integration

time 1 s denotes that a 100 % change is achieved in 1 s.

4003 PID DERIV TIME

PID controller derivation time. If the process error value changes linearly, D part

adds a constant value into the PID controller output. The derivative is filtered

with a 1-pole filter. The time constant of the filter is defined by parameter 4004

PID DERIV FILTER.

4004 PID DERIV FILTER

Time constant for the filter of D part. By increasing the filter time constant it is

possible to smooth the effect of the D part and suppress noise.

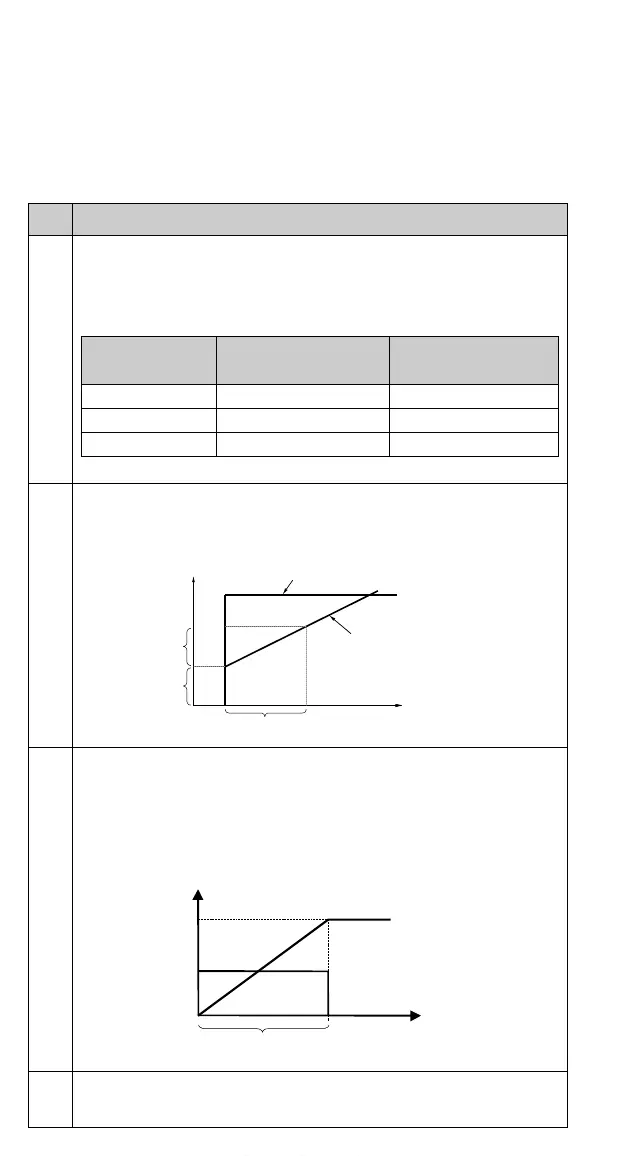

Table 5 Effect of gain when MAXIMUM FREQ is 50 Hz.

PID Gain

Frequency Change for a

10 % Change in Error

Frequency Change for

a 50 % Change in Error

0.5 2.5 Hz 12.5 Hz

1.0 5 Hz 25 Hz

3.0 15 Hz 50 Hz *

Control deviation

PID Controller Output

Gain

Gain

PID Integration Time

t

t

PID derivation time

Gain

Process Error Value

100 %

www.barghmaher.org

Loading...

Loading...