3 Remove the axis-1 motor.

4 Remove the complete arm system (including frame and balancing device)

as a package.

5 Replace the axis-1 gearbox.

6 Refit in reverse order.

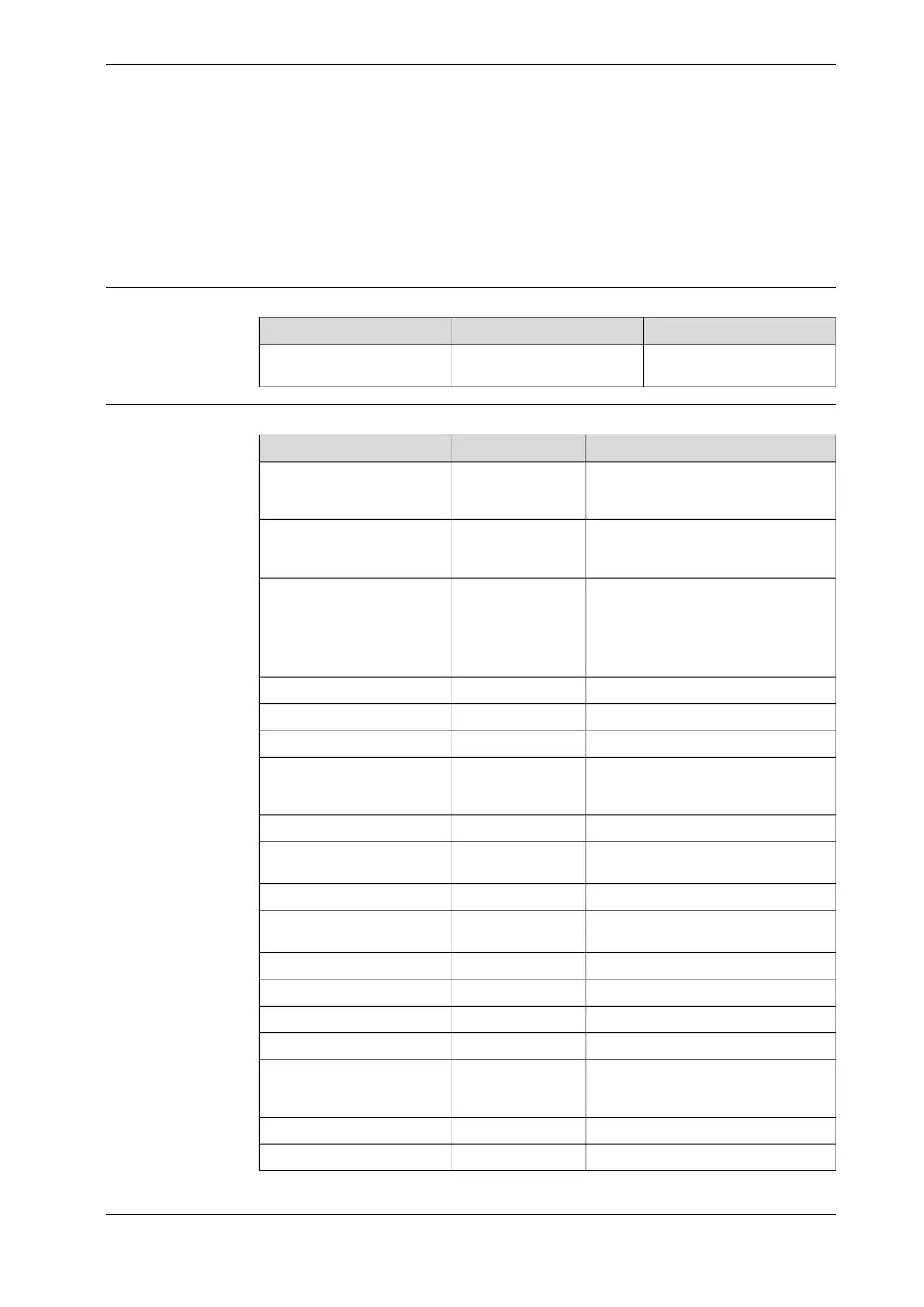

Spare parts

NoteArticle numberSpare parts

See Product manual, spare

parts - IRB 6700/IRB 6700Inv.

Axis-1 gearbox

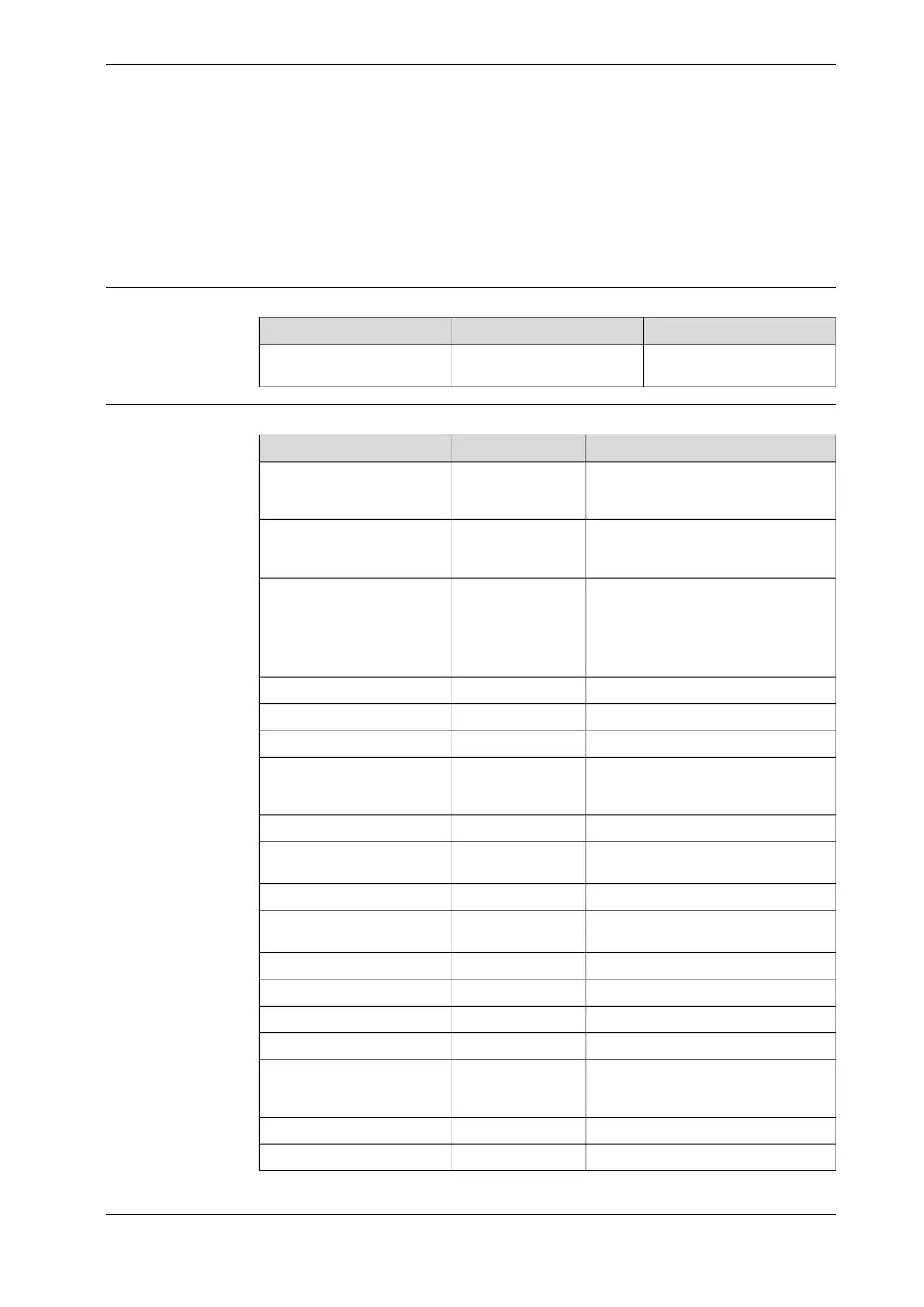

Required tools and equipment

NoteArticle numberEquipment, etc.

The capacity of the vessel must be

sufficient to take the complete amount

of oil.

-Oil collecting vessel

One example of oil dispenser can be

found in section Type of lubrication in

gearboxes on page 156.

-Oil dispenser

Used to push out the motor, if neces-

sary.

Always use removal tools in pairs.

Size depending on motor type, see

Type A vs type B motors on page 819.

3HAC057339-003

3HAC057339-004

Removal tool

300 mm, bits 1/2"3HAC12342-1Bits extender

M123HAC16131-1Lifting eye

M123HAC16131-1Lifting eye

Outer diameter: minimum 26 mm,

maximum 30 mm, hole diameter: 13

mm, thickness: 3 mm.

-Fender washer

SA-10-8-NA1-Lifting shackle

Length: 1.5 m. Lifting capacity: 2,000

kg.

-Roundsling, 1.5 m

Length: 1 m, lifting capacity: 1,000 kg.-Roundsling, 1 m

Lifting instruction 3HAC15880-2 en-

closed.

3HAC15556-1Lifting accessory (chain)

M163HAC14457-4Lifting eye

M163HAC14457-4Lifting eye

3HAC14459-1Lifting accessory, motor

Used to rotate the motor pinion.3HAB7887-1Rotation tool

Used for aligning the gearbox against

the frame, so that the play in the motor

does not need to be adjusted.

3HAC046645-003Aligning tool

Used to release the motor brakes.-24 VDC power supply

Always use guide pins in pairs.3HAC15521-2Guide pin, M10x150

Continues on next page

Product manual - IRB 6700 627

3HAC044266-001 Revision: N

© Copyright 2013 - 2018 ABB. All rights reserved.

4 Repair

4.8.2 Replacing the axis-1 gearbox (IRB 6700 - 300/2.70, IRB 6700 - 245/3.00)

Continued

Loading...

Loading...