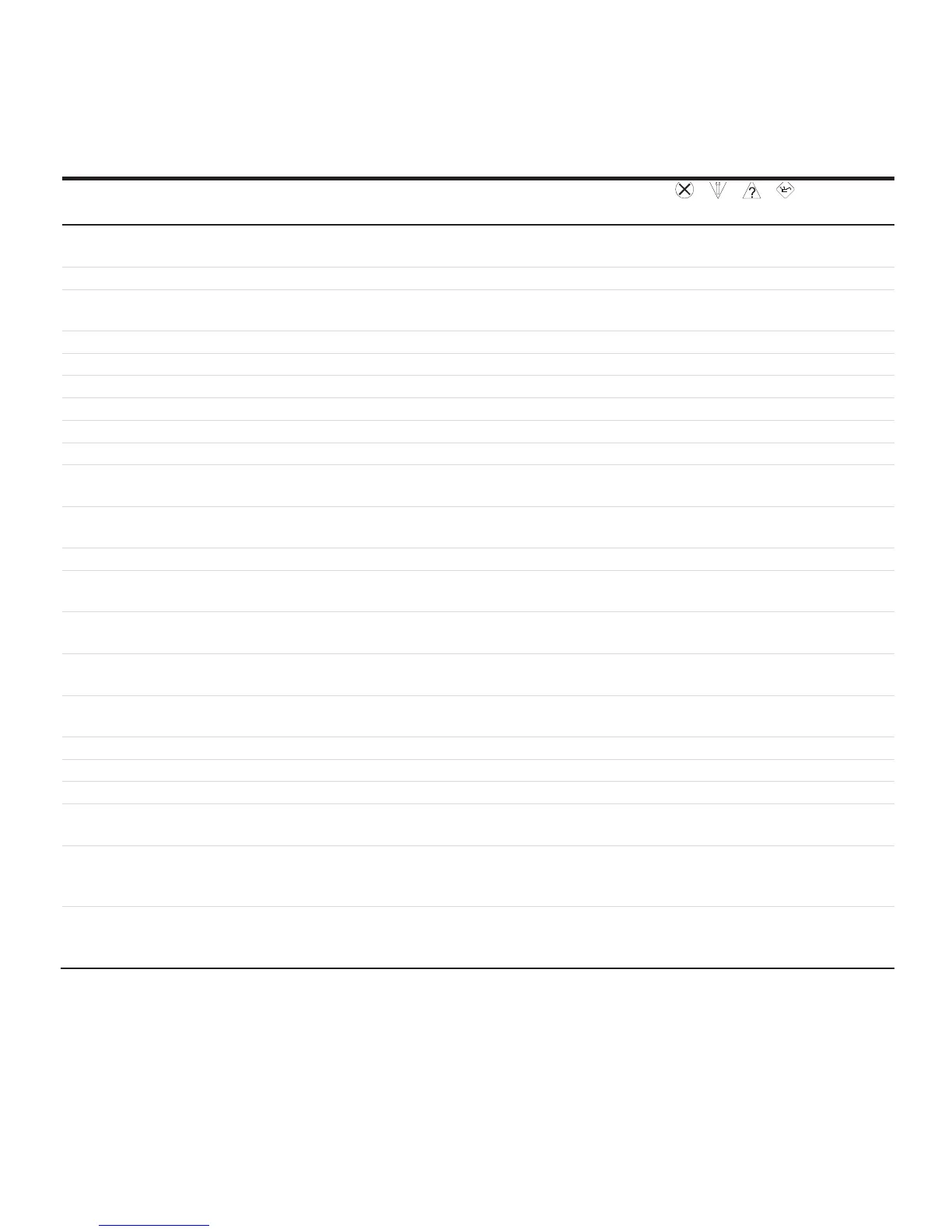

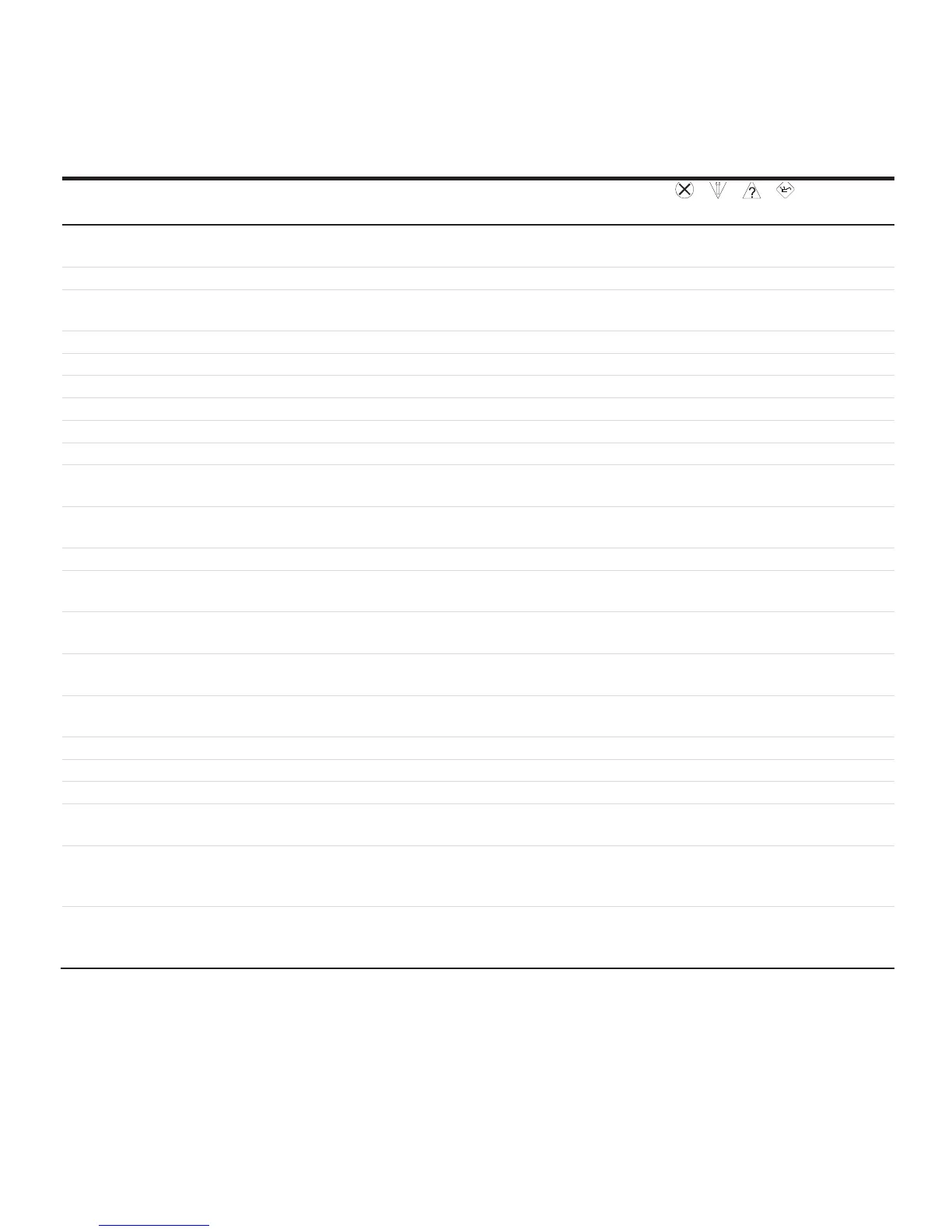

PositionMaster EDP300 DIGITAL POSITIONER | OI/EDP300-EN REV. D 75

Possible error messages

No. Priority Fault message Possible cause Troubleshooting the Instrument

F

C

S

M

Group

1 90 Position measurement

Failure

*

Defective position sensor Replace position sensor X Sensor

2 91 Valve blocked Friction too high Valve requires maintenance X Actuator

3 50 Positioning timeout - Check

valve maintenance

Positioning time up-scaled

friction high

Valve requires maintenance X Actuator

4 51 Positioning unstable Change disturbance variables Select ‘Adaptive Control’ mode X Configuration

5 49 Position out of travel range Mounting kit is bent Check mounting conditions X Process

6 52 Zero-Point displacement Valve seat is damaged Valve requires maintenance X Process

7 43 kp up exceeded Friction too high Valve requires maintenance X

8 44 kp Down exceeded Friction too high Valve requires maintenance X

9 92 Setpoint failure electronics Faulty electronics Replace electronics X Electronics

10 70 Setpoint out of range Defective DCS card Replace DCS card X Special

Requirements

11 80 Device not calibrated Auto adjust has not yet been

executed

Execute auto adjust X Configuration

12 79 Controller inactive Test function activated Test function deactivated X

13 53 Stroke counter limit

exceeded

Many valve strokes Valve requires maintenance X

14 54 Travel counter limit

exceeded

Many valve strokes or vibrating

valve

Valve requires maintenance X

15 55 Electronic temperature

measurement failure

Temperature sensor defective Replace electronics X Electronics

16 71 Electronic temperature out

of limits

Temperature is too high or too

low

Check mounting conditions X Special

Requirements

17 94 Configuration data failure Output piping mixed up Check mounting conditions X Actuator

18 95 Electronics - NV chip defect Faulty electronics Replace electronics X Electronics

19 96 Non volatile data defect Faulty electronics Replace electronics X Electronics

20 56 Leakage during operation Leakage in actuator, piping,

connections, or positioner

Start leakage test X Actuator

21 57 Leakage chamber 1 Leakage in chamber 1 of the

actuator or pneumatics output

line 1

Check chamber 1 of the actuator or

pneumatics output line 1

X Actuator

22 58 Leakage chamber 2 Leakage in chamber 2 of the

actuator or pneumatics output

line 2

Check chamber 2 of the actuator or

pneumatics output line 2

X Actuator

* If the ‘positioning timeout’ alarm has been set, the positioner monitors if the position changes more than 0.1 % over 5 seconds. If not, a ‘Valve Blocked’

diagnosis notice is output. No alarm is output in the end position.

Loading...

Loading...