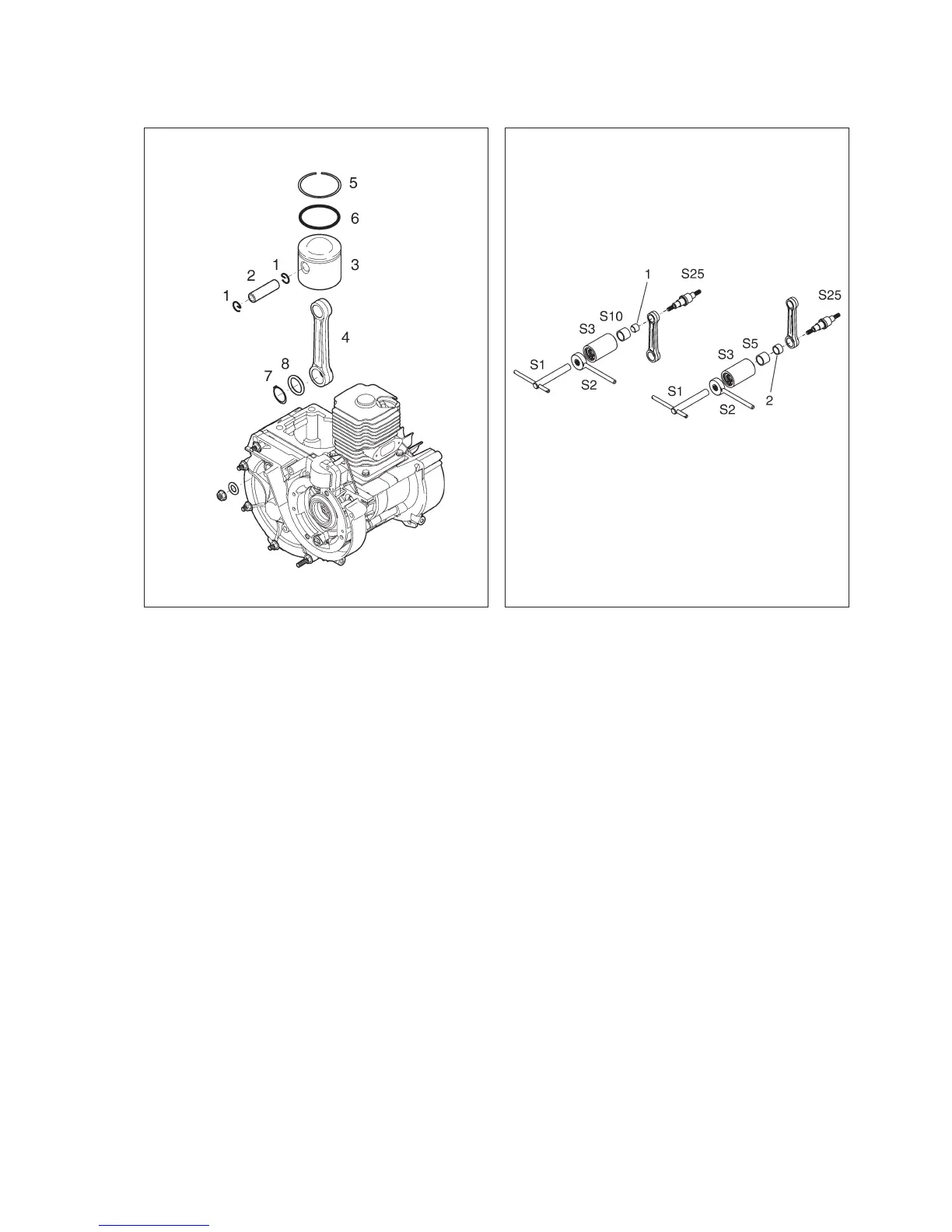

Dismantling of the drive piston

Remove and discard the locking rings (1).

Use a suitable drift to press out the gudgeon pin (2),

supporting the connecting rod and the piston at all

times.

Lift the piston (3) from the connecting rod (4). Re-

move and discard the piston ring (5) and the O-ring

(6).

Examine the grooves and the surfaces of the piston,

and replace if damaged or worn.

Dismantle the locking ring (7) and the washer (8); the

locking ring must be discarded. Lift the connecting

rod (4) from the hammer piston crankshaft.

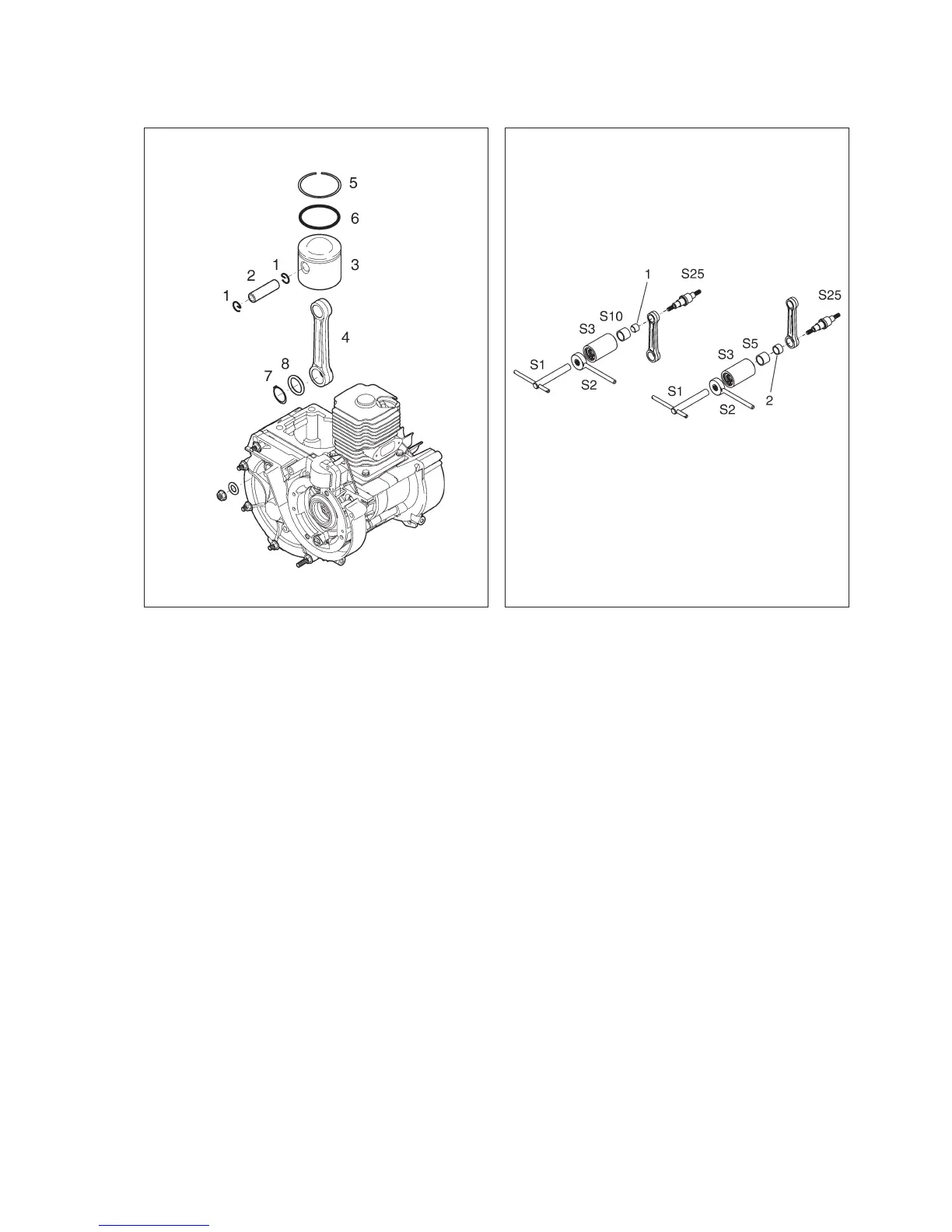

Dismantling and reassembly of the

connecting rod bearings

Dismantle the needle bearing (1) using service tools

S1, S2, S3, S10 and S25.

Fit a new bearing using service tools S1, S2, S3 and

S25.

Dismantle the needle bearing (2) using tools S1, S2,

S3, S5 and S25.

Note: Once it has been dismantled, a needle bearing

must not be re-used and must be discarded.

21

Fig. 23

Fig. 24

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

Loading...

Loading...