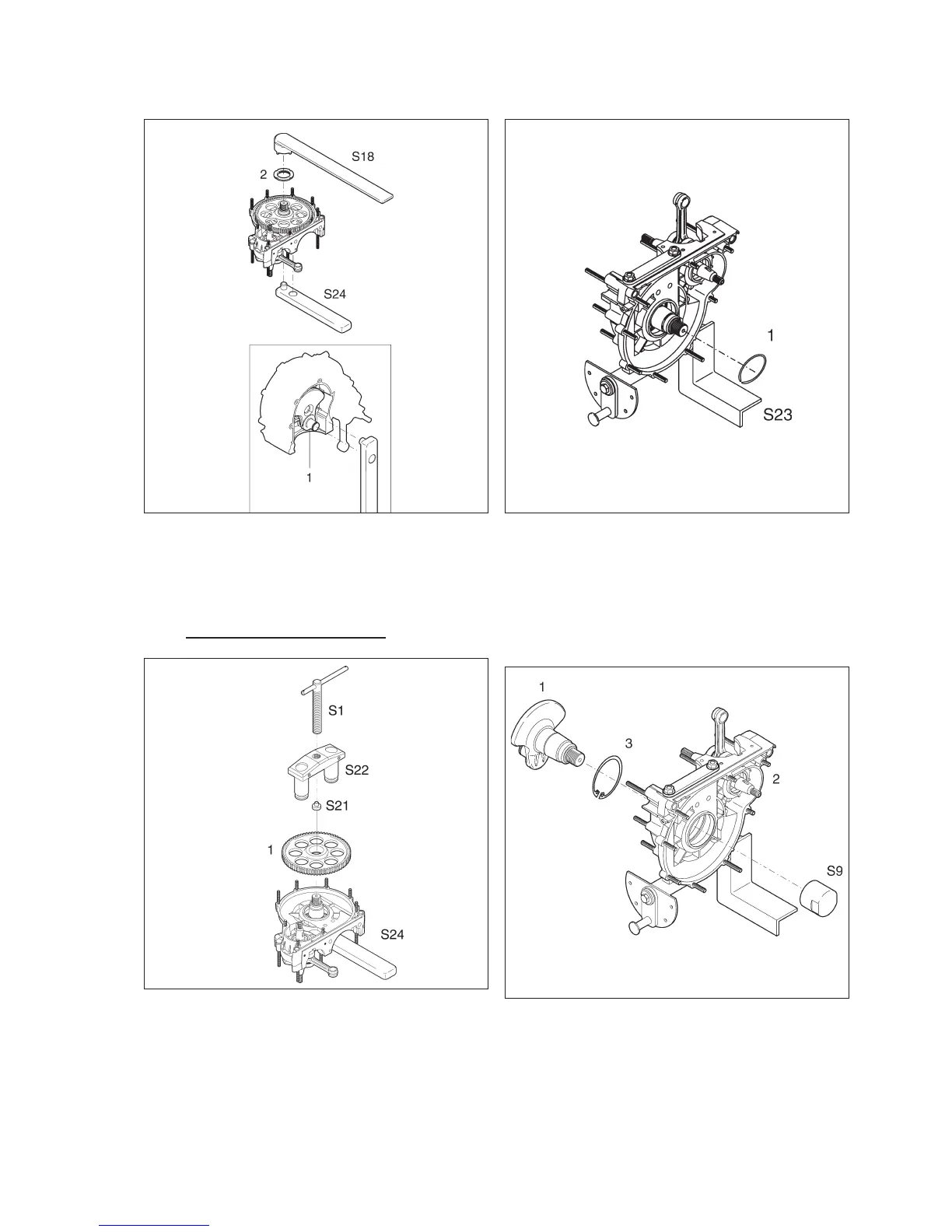

Dismantling of the hammer

crankshaft gear wheel

Dismantle the engine from fixture S23. Fix service

tool S24 in the swivel vice.

Place the pin of the tool in the hole in the hammer

crankshaft.(1).

Use tool S18 to remove the nut (2).

Note: The nut has a left-hand thread.

Dismantle the gear wheel (1) using tools S1, S21 and

S22. Examine the gear teeth for wear; the gear wheel

must be replaced if they are worn or damaged.

Note: If the hammer crankshaft gear wheel is re

-

placed, the engine crankshaft gear wheel must also

be replaced.

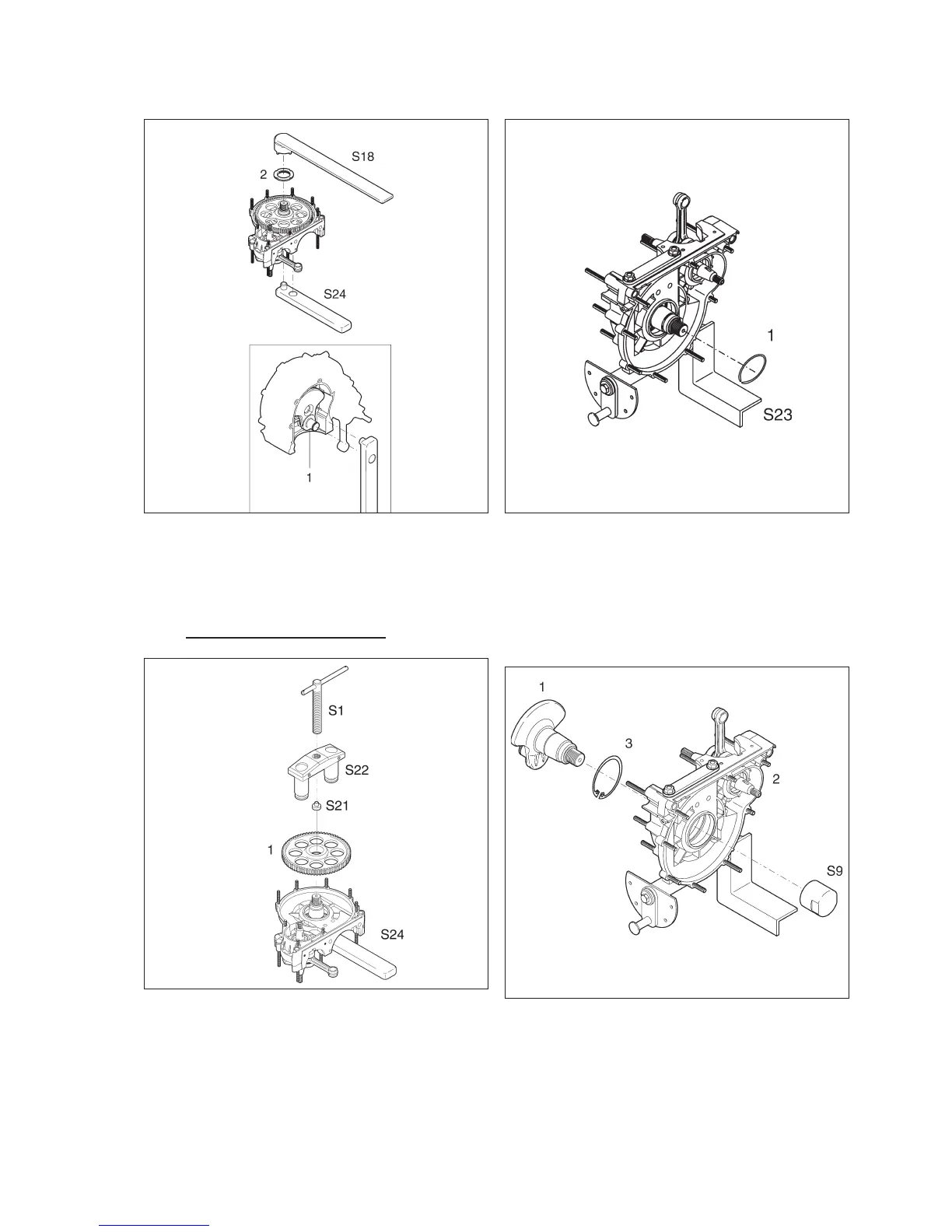

Dismantling of the hammer

crankshaft

Fix the engine half in fixture S23.

Dismantle the locking ring (1).

The locking ring is deformed during removal and

must be discarded.

Note: A groove is present in the crankshaft to facili-

tate removal.

Dismantle the locking ring (3).

Fit service tool S9 on the hammer crankshaft (1).

Use a rubber hammer to knock out the hammer

crankshaft from the crankcase half (2).

25

Fig. 32

Fig. 33

Fig. 34

Fig. 35

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

Loading...

Loading...