Design and function

Engine

The machine is powered by a single-cylinder,

air-cooled two-stroke engine. The engine is

equipped with a diaphragm carburettor, which is con-

trolled by changes in pressure inside the crankcase.

The carburettor feeds the fuel mixture into the cylin-

der via a diaphragm valve. The engine is automati-

cally lubricated by the oil in the fuel mixture.

The speed of the engine can be varied by the hand

throttle, which is connected to the carburettor butter-

fly valve.

The maximum speed of the engine is restricted by an

electronic speed restrictor, which is incorporated in

the breakerless ignition system.

The power transmission between the engine and

hammer mechanism is via a gear assembly.

Hammer mechanism

Before starting the engine, the hammer piston rests

on the tool shank. When the engine is started, the

drive piston commences to move up and down in the

hammer cylinder.

When the handles are pushed down, the tool raises

the hammer piston in the hammer cylinder and the

hammer mechanism is activated.

When the machine is lifted, the tool drops down onto

the tool latch. The hammer piston moves into its

lower position, where it stops, and the hammer

mechanism is disengaged.

This operational system also means that the ma-

chine can stand on a tool without engaging the ham-

mer piston.

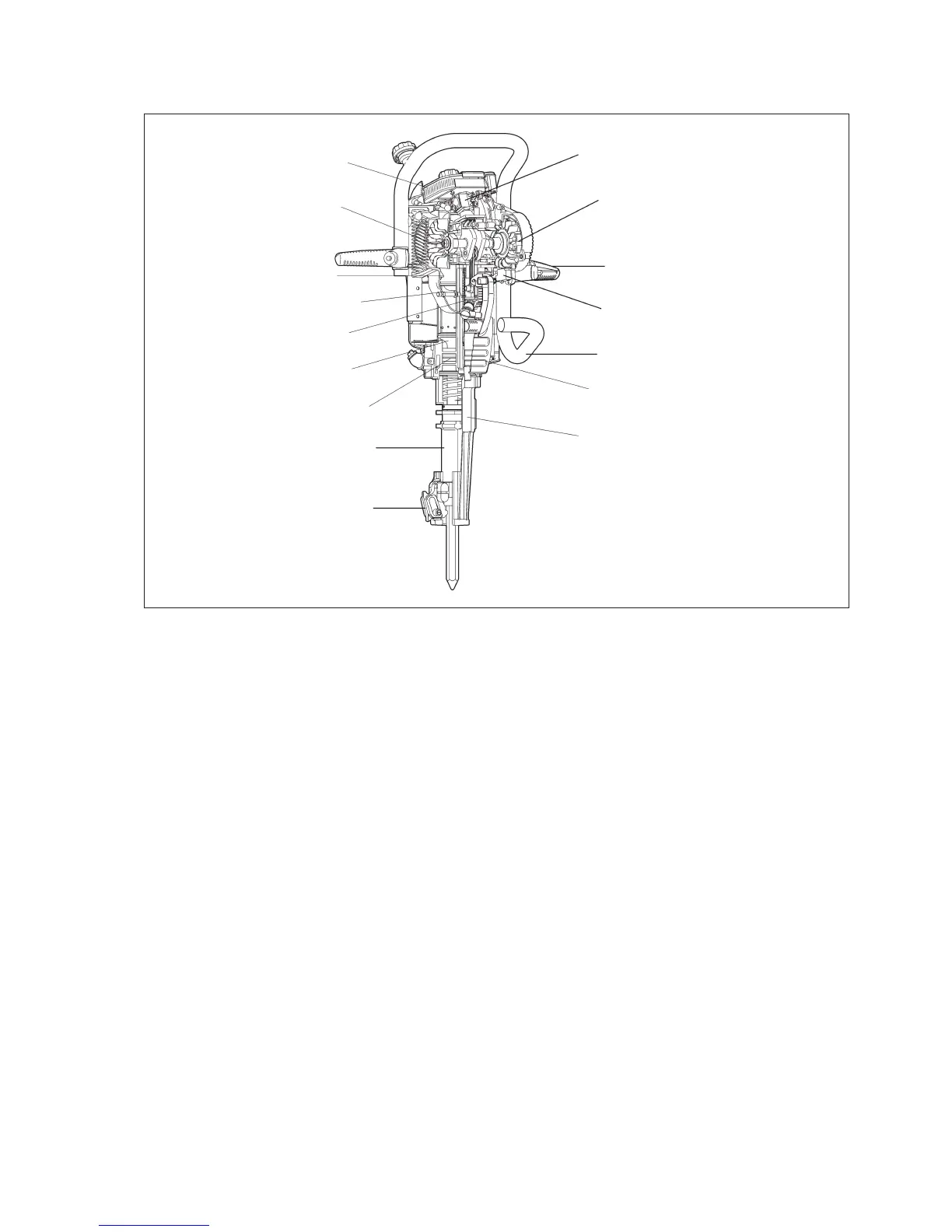

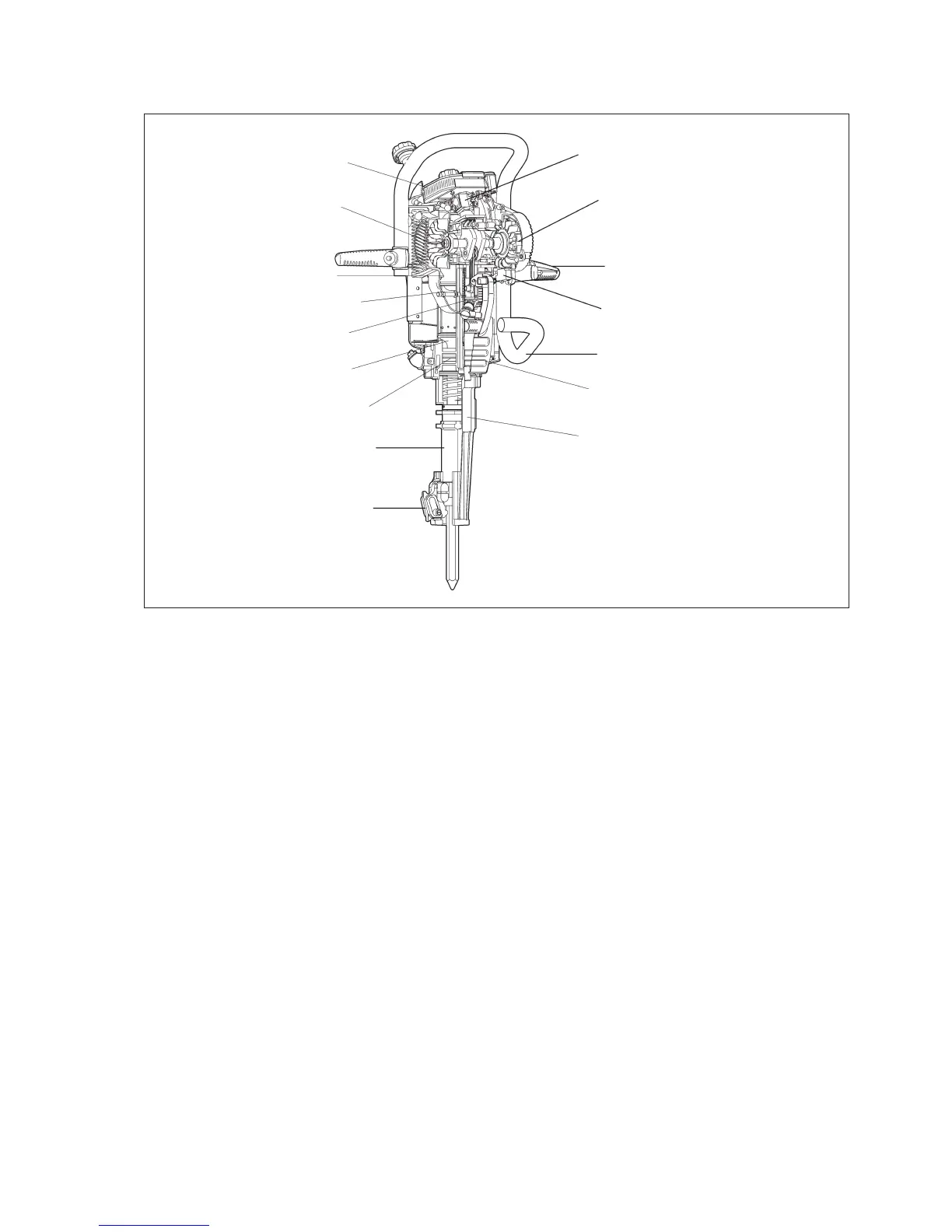

7

Air Filter

Cooling Fan

Drive piston

Decompression valve

Engine cylinder

Hammer piston

Hammer piston guide

Tool chuck

Tool latch

Carburettor

Starter mechanism

Throttle

Electronic unit

Fuel tank

Muffler

Tool holder

Loading...

Loading...