Reassembly

Fit the throttle cable(9) and the electrical wires (5)

and (6) in the protective sheath (11).

Push the wires down through the hole for the bush

(10) and then up through the hole for the stop button.

Connect the wires to the stop button and then fit the

stop button in the handle.

Note: Check that the stop button is installed in the

right direction.

Push the cable down through the hole for the bush

(10) and then up through the hole for the throttle lever.

Hook the cable onto the throttle lever.

Fit the throttle lever in the handle and tap in the pin

(7). Stretch the cable and the electrical wires and

check that the electrical wires do not interfere with

the throttle lever and cable.

Fit the nipple (10).

Pass the cable down into the nipple and check that it

bottoms.

Pass the protective sheath over the nipple (10).

Fit the handle (2), washer (12) and locking nut (1) to

the handle strap. Fix the handle in the correct posi-

tion on the fuel tank and tighten the handle locking

nut (1).

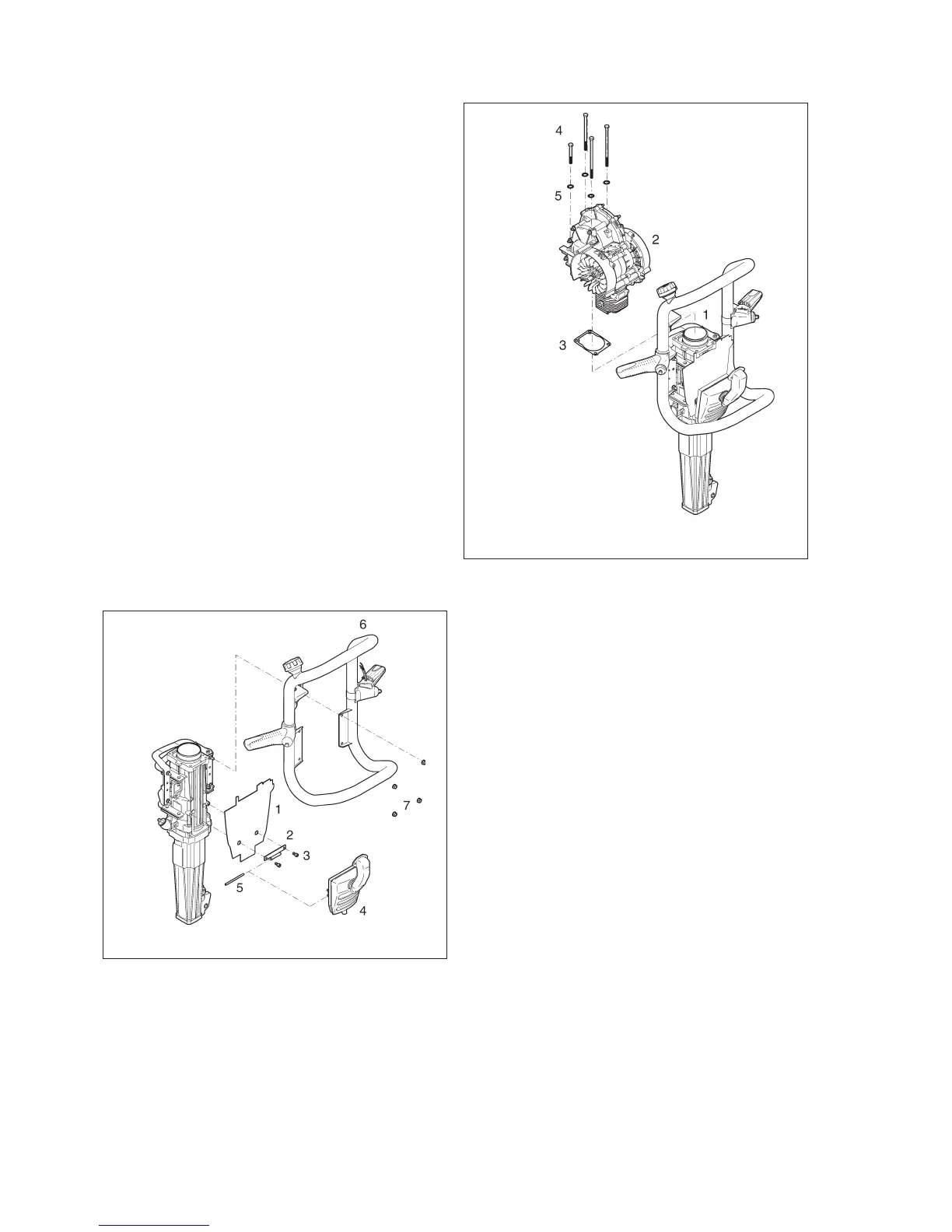

Reassembly of fuel tank and

muffler

Locate the heat shield (1) on the hammer cylinder.

Note: Check that the heat shield is facing in the cor-

rect direction.

Fit the bracket (2) with the screws (3). Fit the muffler

(4) to the bracket (2) and tap in the spring pin (5).

Fit the fuel tank (6) to the end stop and tighten the

nuts (7).

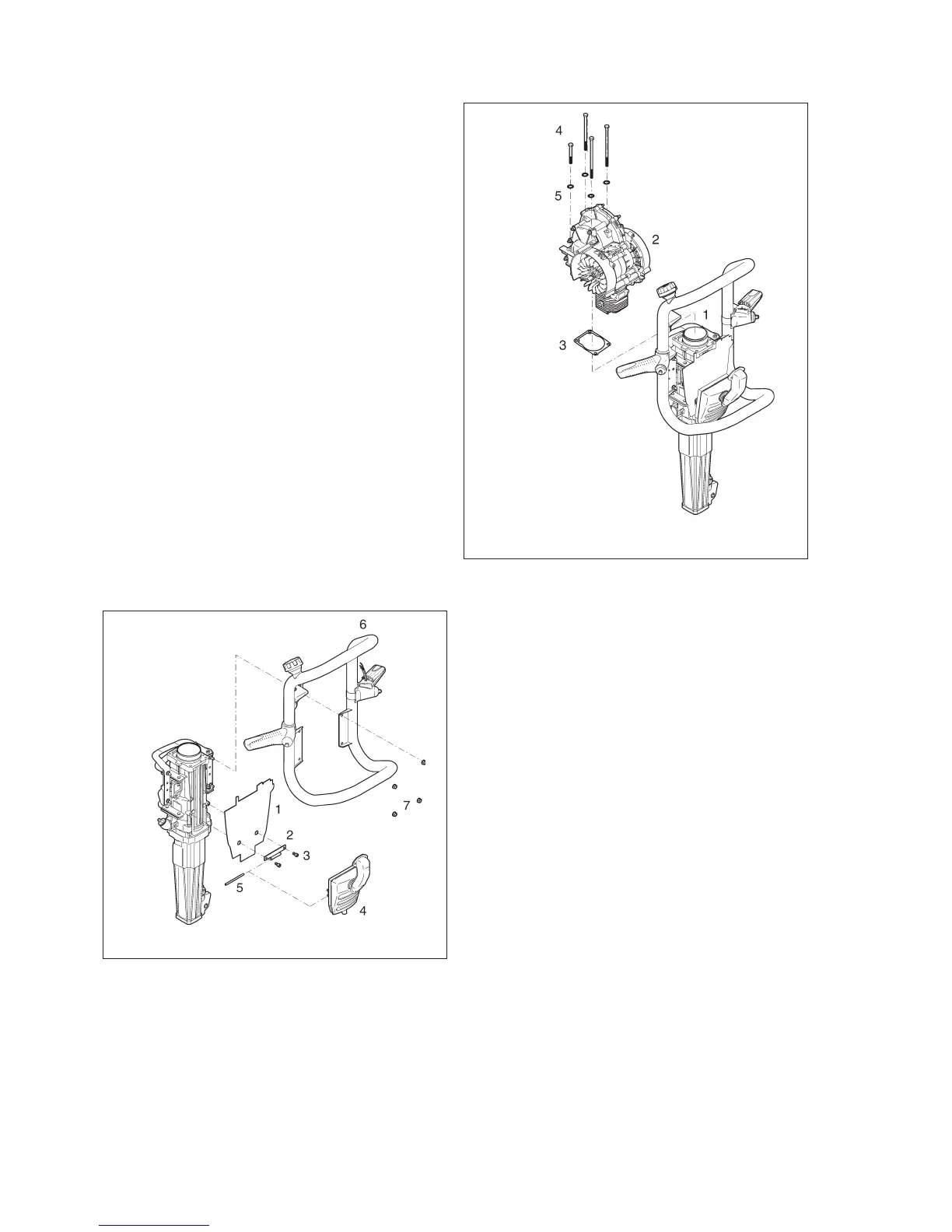

Reassembly of engine

Lubricate the hammer cylinder bore (1) and the drive

piston.

Place a new gasket (3) on the hammer cylinder.

Position the drive piston in the hammer cylinder bore

and lower the engine (2) carefully onto the hammer

cylinder.

Tighten the engine mounting screws (4) together

with the washers (5). The screws must be tightened

to the stipulated torque load.

Note: The mounting screws (4) must be provided

with washers (5) to enable the correct tightening

torque load to be contained.

36

Fig. 69

Fig. 70

Loading...

Loading...