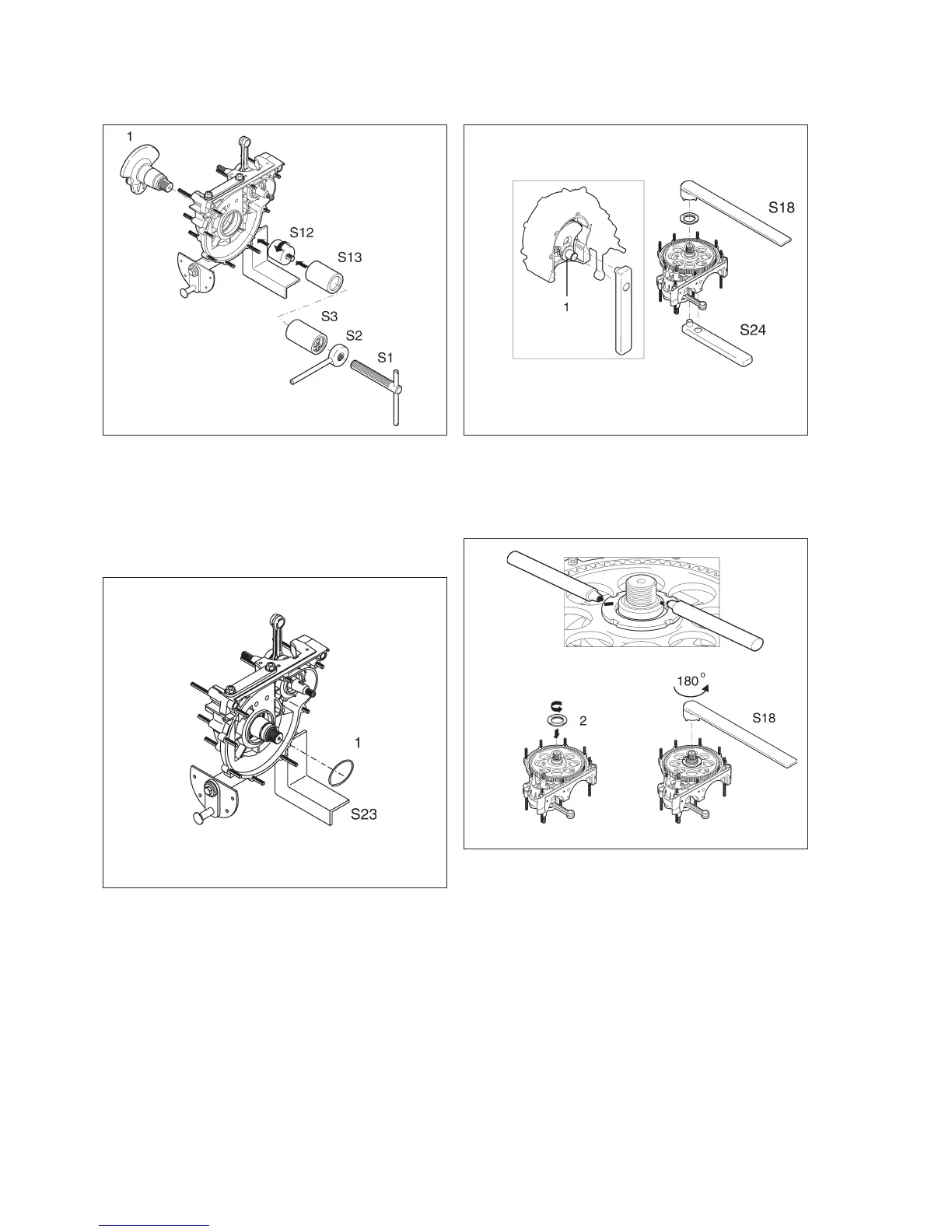

Reassembly of hammer crankshaft

Fit the hammer crankshaft (1) in the crankcase using

service tools S1, S2, S3, S12 and S13.

Reassembly of locking ring on

hammer crankshaft

Fit a new locking ring on the hammer crankshaft.

Check carefully that the locking ring is correctly

seated in the groove.

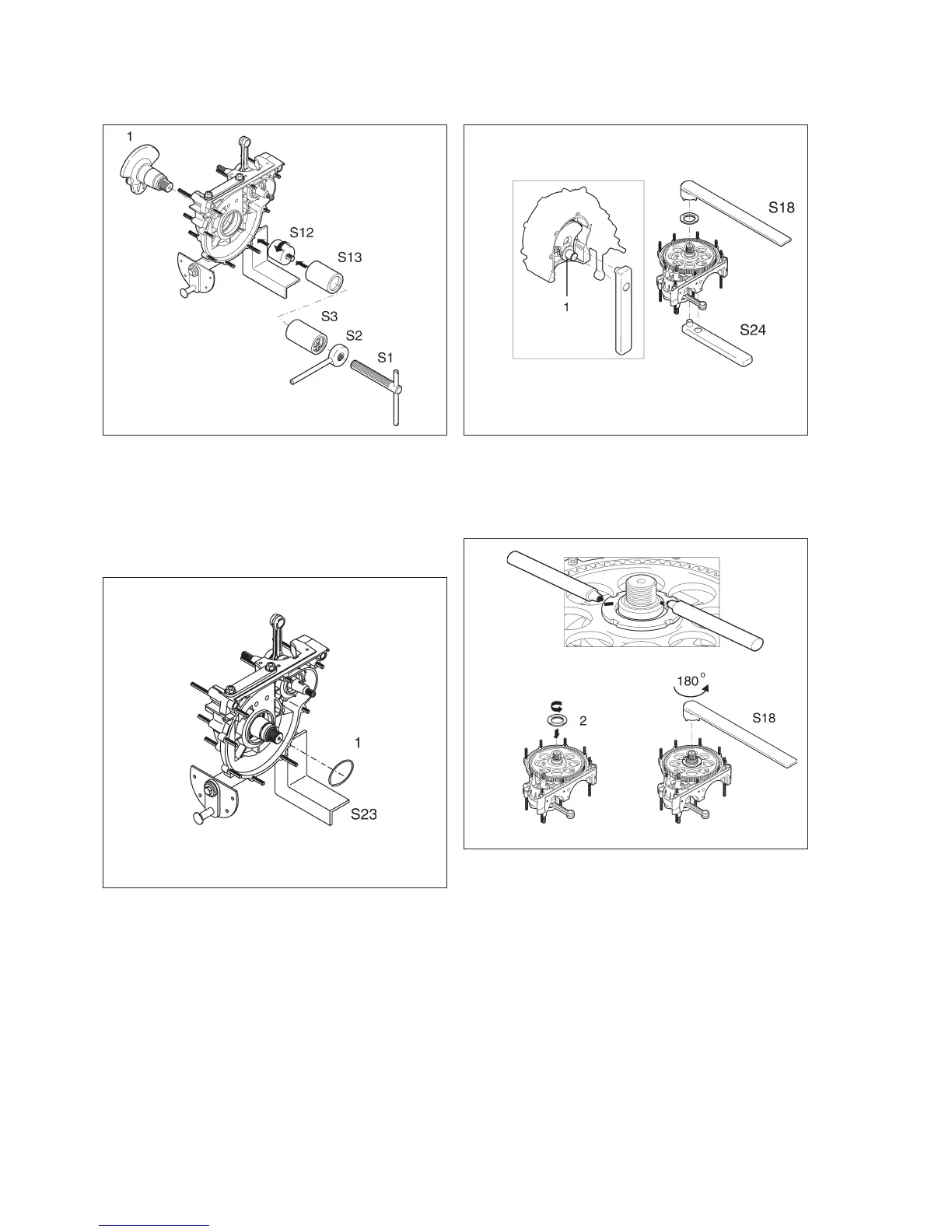

Reassembly of hammer crankshaft

gear wheel

Dismantle the engine crankcase from the fixture S23.

Fix service tool S24 in the swivel vice.

Locate the pin of the tool in the hole on the hammer

crankshaft.

Degrease the hammer crankshaft and gear wheel

taper with a suitable degreasing agent.

Both tapers must be totally clean and free from

grease to ensure a secure grip between the gear

wheel and the crankshaft.

Thread on the nut (2) and tighten it by hand until the

nut makes contact with the gear wheel.

Note: The nut has a left-hand thread.

Make a mark on the nut (2) with a marker pen and

another mark on the other side on the end of the

crankshaft.

Use tool S18 to tighten the nut by half a turn (180°),

i.e. until the markings are directly in line with one an

-

other.

28

Fig. 44

Fig. 45

Fig. 46

Fig. 47

Loading...

Loading...