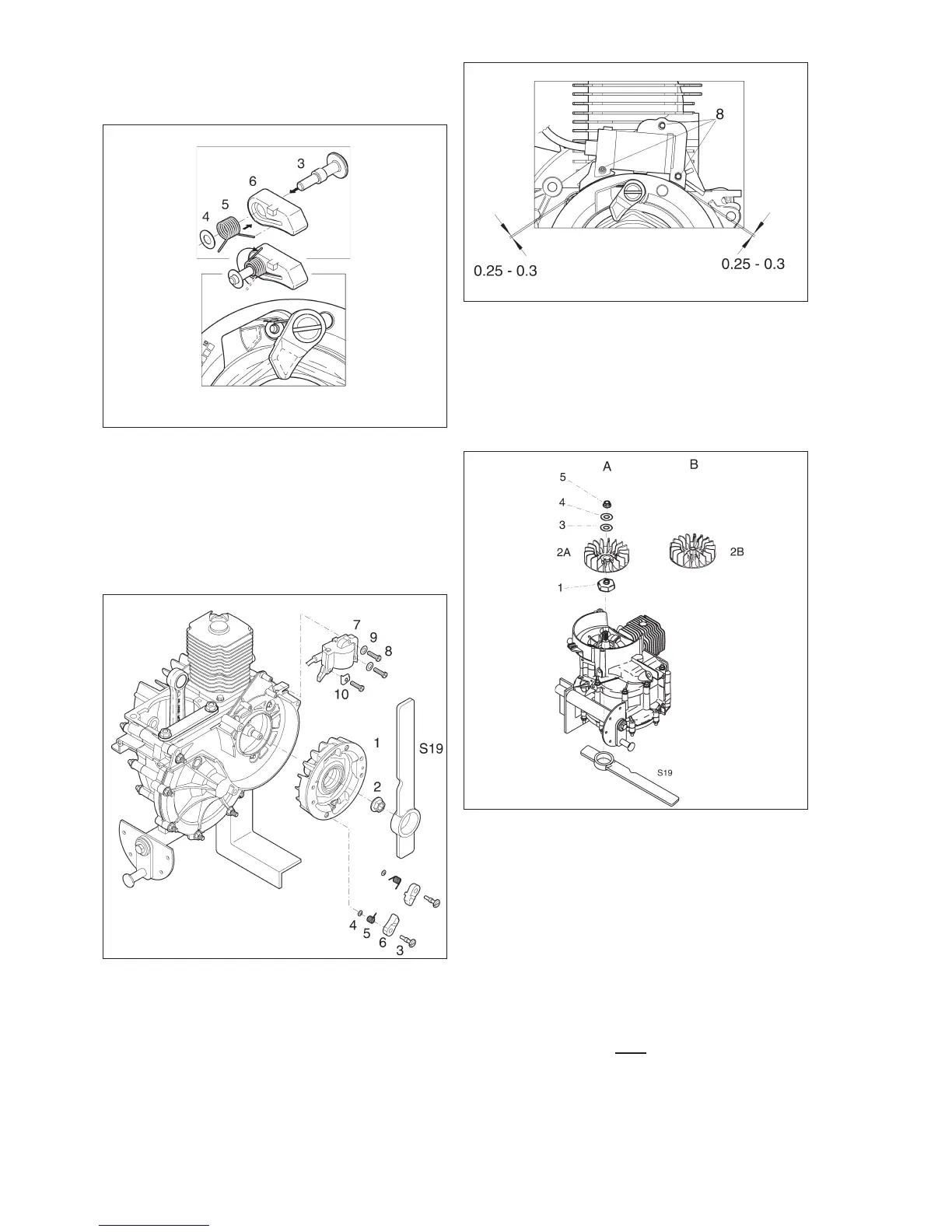

Reassembly of the carrier, flywheel

and electronics unit

Insert the screw (3) washer (4) and carrier spring (5)

in the carrier (6).

Preload the spring by half a turn and introduce the

carrier into place in the flywheel.

Check that the end of the spring is correctly engaged

in the groove. Tighten the screw (3) to the stipulated

torque load.

Fit the flywheel (1) to the crankshaft. Lock the fly-

wheel using service tool S19 and tighten the nut (2)

to the stipulated torque load.

Fit the electronics unit (7) to the crankcase using the

three screws (8) and the washers (9) and (10).

Note: The washer (10) is designed to prevent dam

-

age to the plastic case when the screw is tightened.

Tighten the three screws (8) slightly and adjust the

gap between the flywheel magneto and the electron-

ics unit to 0.25 – 0.3 mm.

Tighten the screws (8) to the stipulated torque load.

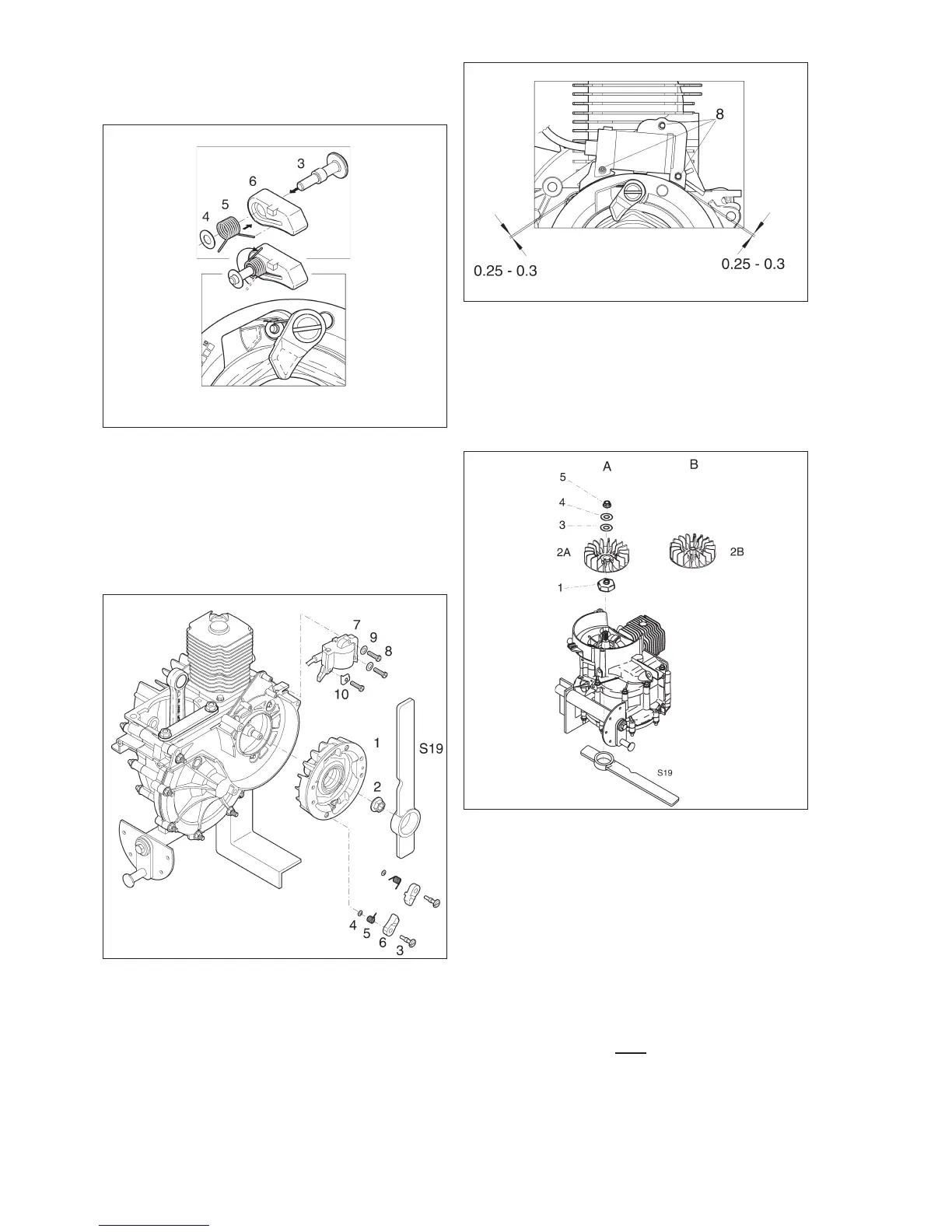

Reassembly of cooling fan

Type A

Locate the hub (1) on the crankshaft taper.

Fit the fan (2A), flat washer (3), spring washer (4)

and nut (5).

Lock the flywheel using service tool S19 and tighten

the nut (5) to the stipulated torque load.

Type B

Note. The crankshaft taper and the internal taper of the

fan must be thoroughly degreased before assembly.

White spirit or a similar degreasing agent must be

used.

Lock the flywheel with service tool S19 and fit the fan

to the crankshaft.

Note. A torque wrench must

be used for tightening,

and the fan must be tightened to the stipulated

torque load of 8 Nm

32

Fig. 57

Fig. 58

Fig. 59

Fig. 60

Loading...

Loading...