Specific Application Considerations

6.3 Cooling Tower/Boiler Systems

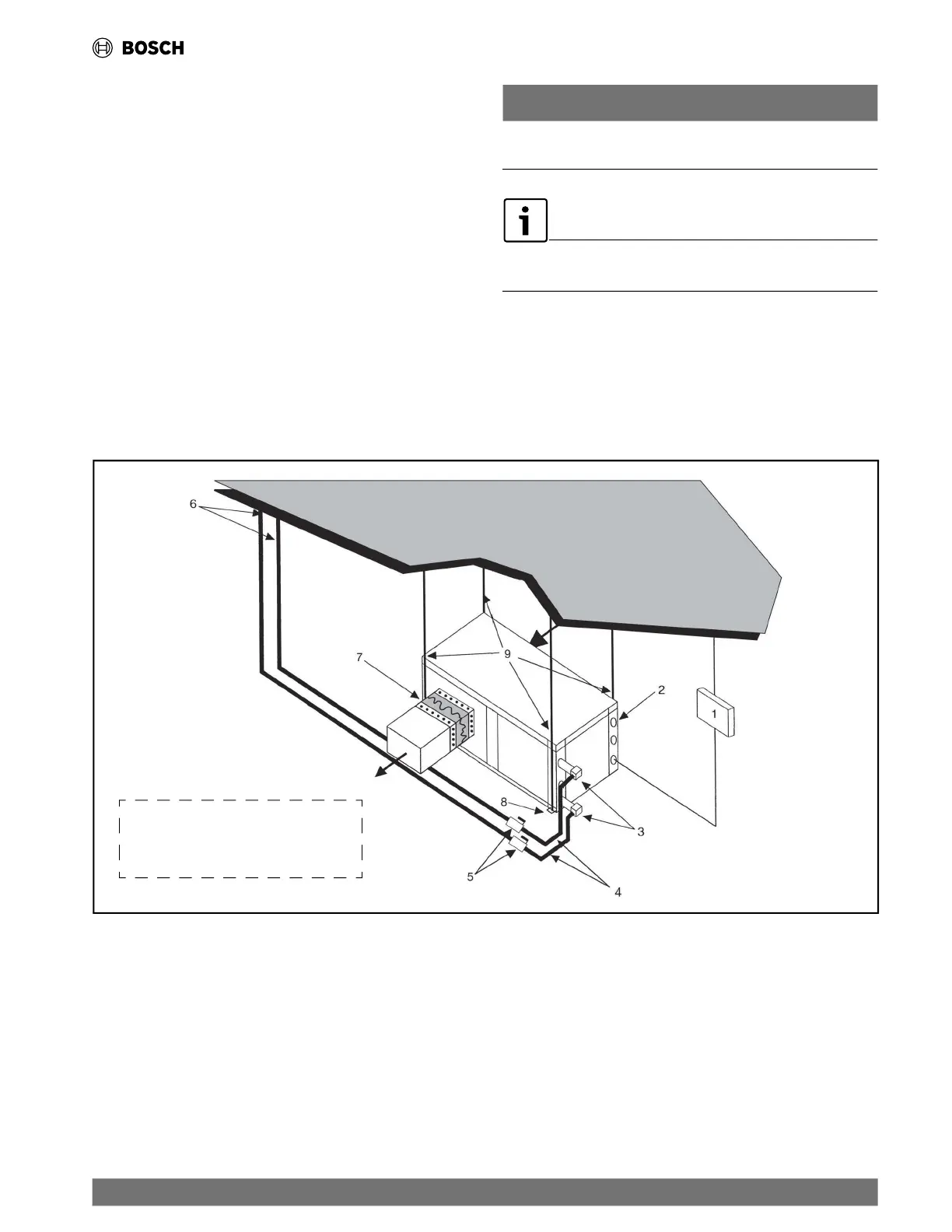

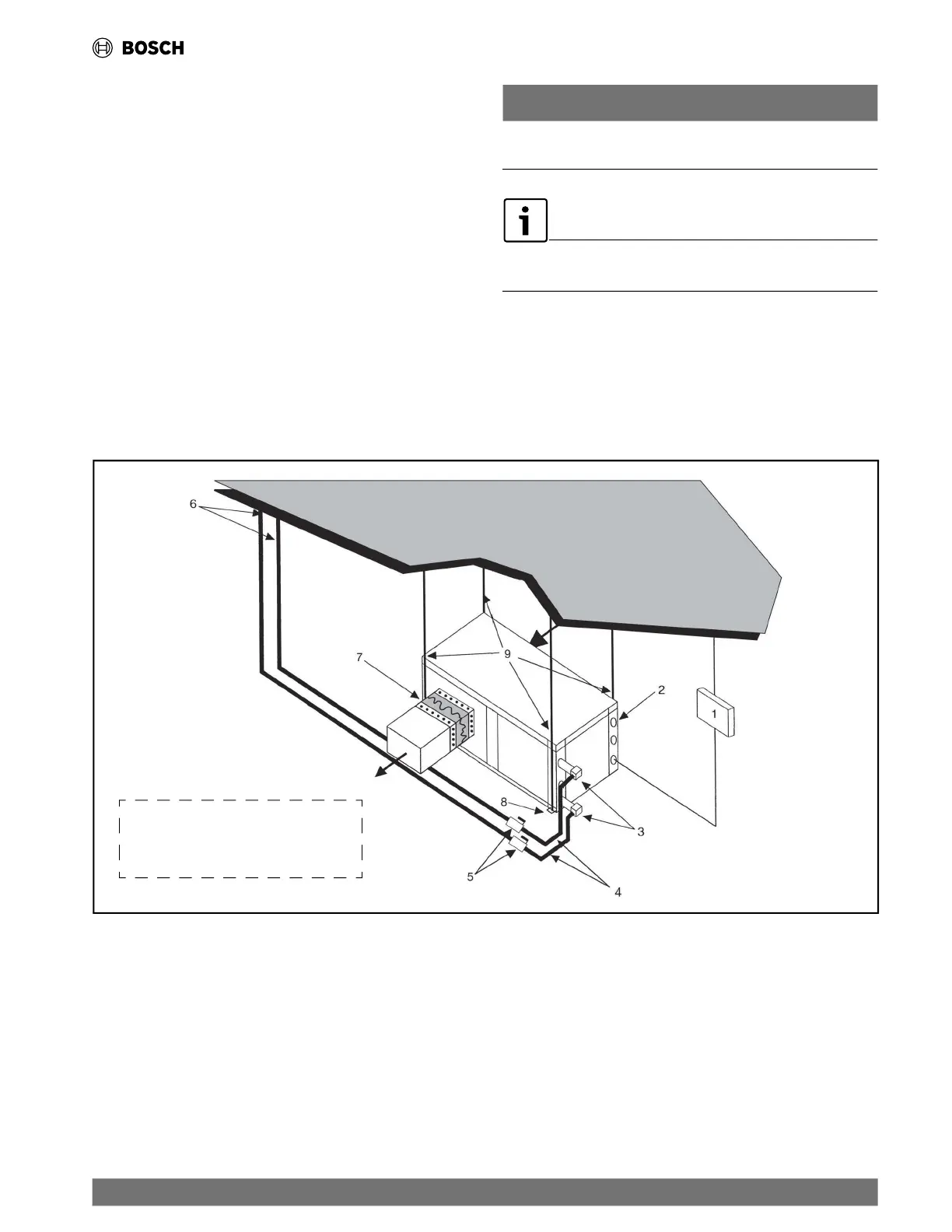

(Refer to Fig. 16)

These systems typically use a common loop temperature

maintained a

t 50°F to 100°F to ensure adequate cooling and

heating performance.

In the cooling mode, heat is rejected from the unit into the water

loop. A cooli

ng tower provides cooling to the loop water thus

maintaining a constant supply temperature to the unit. When

utilizing open cooling towers, chemical water treatment is

mandatory to ensure the water is free from corrosive elements. A

secondary heat exchanger (plate frame) between the unit and

the open cooling tower may also be used. It is imperative that all

air be eliminated from the closed loop side of the heat exchanger

to ensure against fouling. In the heating mode, heat is absorbed

from the water loop. A boiler can be utilized to maintain the loop

at the desired temperature.

NOTICE

Water piping exposed to extreme low ambient temperatures is

subject to freezing.

To ensure against leaks and possible heat exchanger fouling,

use an appropriate thread sealant.

Consult the dimensional drawings starting on page #88 for

piping sizes.

To avoid possible vibration, use flexible hoses between the unit

and the rigid

system. For unit isolation and unit water-flow

balancing, install ball valves in the supply and return lines.

Fig. 16 Typical Cooling Tower and Boiler System Setup

This diagram shows a typical installation

and is for illustration purposes only. Ensure

access to Heat Pump is not restricted.

[1] Line-Voltage Disconnect (unit)

[2] Low-Voltage Control Connection

[3] P/T Plugs (optional)

[4] Hose Kits

[5] Ball Valves

[6] Supply and Return Line of Central System

[7] Flex Duct Connection

[8] Hanging Bracket Assembly

[9] Threaded Rod

|

25

CL Series Heat Pumps — 8733838716 (2024/05)

Loading...

Loading...