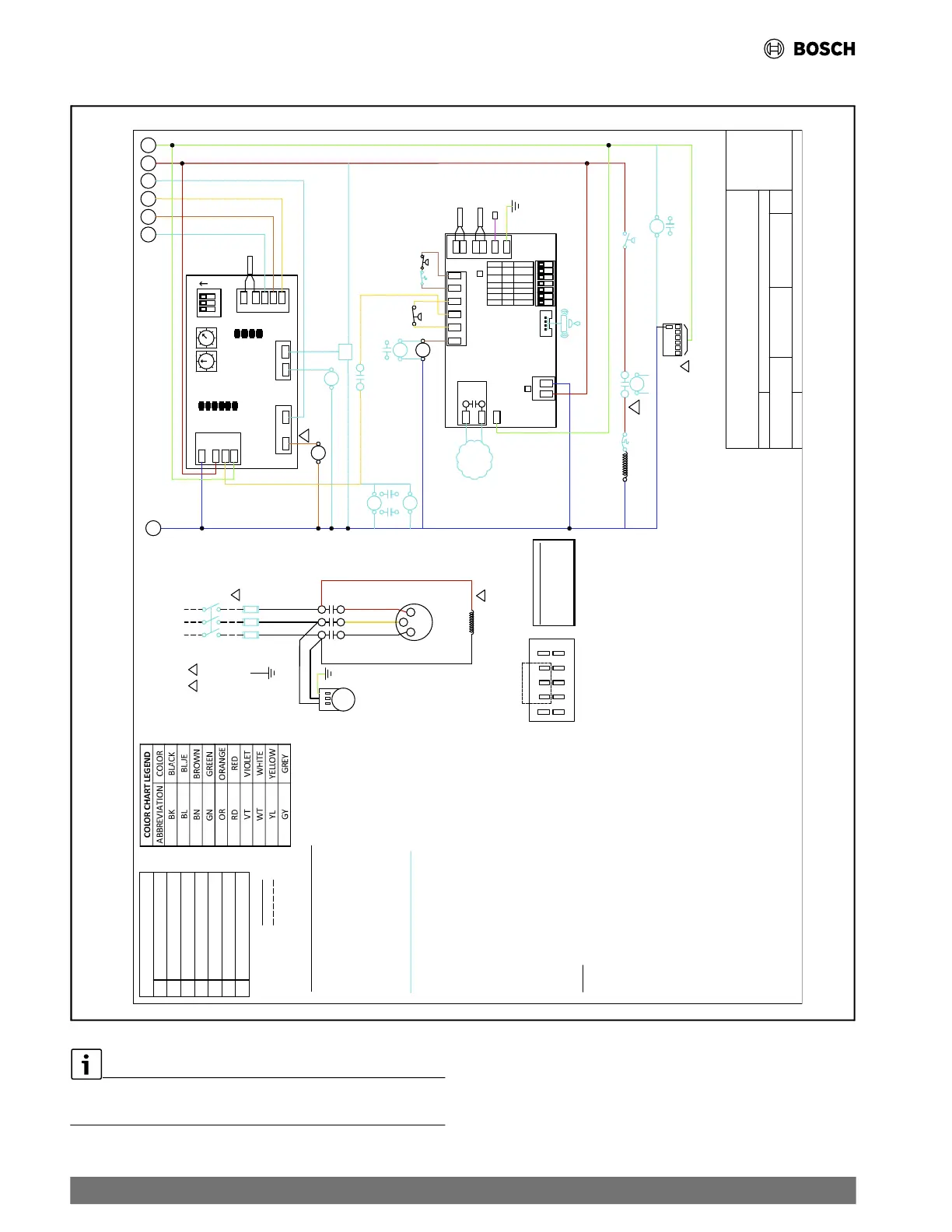

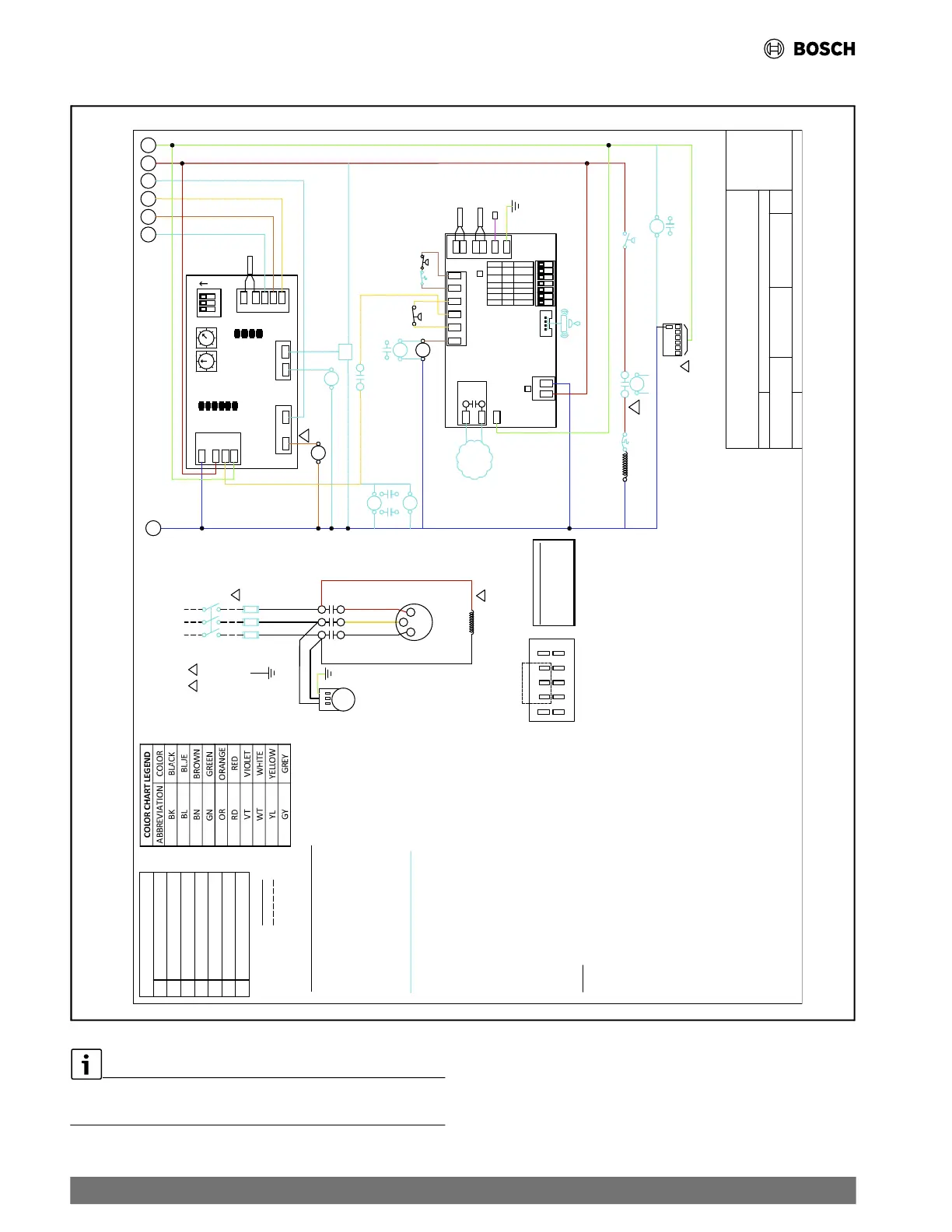

21.15 Single-Stage, Three-Phase Unit with Optional Components and CT Motor

Fig. 43 Single-Stage, Three-Phase Unit with Optional Components with CT Motor

PART No.

C

OY RG

24

EMS

RV

BMR

DPS

AUX

LWV

HGV

LWV

FACTORY WIRE

FIELD WIRE

OPTIONAL COMPONENTS LEGEND:

[ ] A2L - AIR TO LIQUID REFRIGERANT LEAK SENSOR

[ ] AUX - AUXILIARY RELAY

(FOR LOOP PUMP, ETC)

[ ] BMR - BLOWER MONITOR RELAY

[ ] CBR - 24V CIRCUIT BREAKER (75VA & 100VA ONLY)

[ ] CMR - COMPRESSOR MONITOR RELAY

[ ] DPS - DIFFERENTIAL PRESSURE SWITCH

[ ] DS - DISCONNECT SWITCH

[ ] EMS - ENERGY MGMT SYSTEM RELAY

[ ] FB - FUSE BLOCK (FOR 100KA SCCR RATING)

[ ] HGV - HOT GAS VALVE SOLENOID

[ ] HSL - HIGH TEMPERATURE SUCTION LIMIT

(WITH HOT GAS BYPASS ONLY)

[ ] LWV - LEAVING WATER VALVE

[ ] MBV - MOTORIZED BALL VALVE

STANDARD COMPONENTS LEGEND:

BM - BLOWER MOTOR

CAP - COMPRESSOR CAPACITOR

CC - COMPRESSOR CONTACTOR

CS - CONDENSATE SENSOR (IN DRAIN PAN)

FS - FREEZE SENSOR

HPS - HIGH PRESSURE SWITCH

LPS - LOW PRESSURE SWITCH

RV - REVERSING VALVE (HEAT PUMPS)

NOTES:

1. SEE UNIT NAME PLATE FOR ELECTRICAL RATING.

2. ALL FIELD WIRING MUST BE IN ACCORDANCE WITH

N.E.C.-N.F.P.A. #70, COPPER CONDUCTORS ONLY - CONDUCTEURS EN CUIVRE SEULEMENT.

3. 208/230V UNITS ARE FACTORY WIRED FOR 230V OPERATION. FOR 208V OPERATION,

REMOVE PRIMARY LEAD FROM 240 TERMINAL AND CONNECT IT TO 208. CAP ALL UNUSED TERMINALS.

4. FOR ALTERNATE EMS COIL VOLTAGES CONSULT FACTORY.

5. UPM-I INCLUDES BUILT IN: 270-300 SECOND RANDOM START

300 SECOND DELAY ON BREAK

120 SECOND LOW PRESSURE BYPASS

6. "TEST" DIP SWITCH REDUCES DELAYS TO 10 SEC WHEN SET TO YES. MUST BE SET TO "NO" FOR NORMAL OPERATION.

7. "FREEZE SENSOR" ON CONDENSER WILL BE SET TO 25°F OPERATION BY DEFAULT, IF 15°F OPERATION IS REQUIRED,

MOVE DIP SWITCH SLIDER TO THE 15°F POSITION.

8. "ALARM OUTPUT" DIP SWITCH MUST BE SET TO "PULSE" IF BLINKING T-STAT SERVICE LIGHT IS DESIRED OR IF DDC

CONNECTION IS AVAILABLE. CONT FOR NON BLINKING THERMOSTAT CONNECTION.

9. DEFAULT SETTINGS FOR UPM BOARD FROM FACTORY SHOWN. ALSO SEE INSTALLATION MANUAL.

10. ALARM OUTPUT IS NORMALLY OPEN (NO) DRY CONTACT. IF 24 VAC IS NEEDED, CONNECT R FROM TERMINAL BLOCK

TO ALR-COM TERMINAL, 24VAC WILL BE SENSED ON THE ALR-OUT WHEN THE UNIT IS IN ALARM CONDITION. OUTPUT

WILL BE PULSED IF PULSE IS SELECTED.

11. REVERSING VALVE NOT PRESENT ON UNITS WITH STRAIGHT COOL.

12. REFER TO UNIT IOM FOR FACTORY DEFAULT MOTOR SPEED INSTALLATION SETTINGS AND AVAILABLE PROGRAMMED

SPEED PINS.

13. UNIT WILL HAVE OPTIONAL DISCONNECT SWITCH OR FUSE PROTECTION, UNIT WILL NOT HAVE BOTH.

H

ECM TERMINAL CONNECTIONS

N - L2

G - GROUND

L - L1

C - 24V COMMON

1-5 - SPEED TAPS

N

G

L

C

34

5

HIGH VOLTAGE

MOTOR CONNECTIONS

1

2

ECM TERMINAL CONNECTIONS

12

BK

BK

SEE NOTES 5 - 10

LED1

EC

BC

OPTION CARD

OFF

LED2

LED3

LED4

H

O

Y

R

LED5

LED6

LED7

LED8

Y_OUT

G_OUT

O_OUT

W_OUT

LED9

LED10

H_OUT

E_OUT

-30F

100F

20 50

-30F

100F

20 50

POT

HEAT_SP

POT

COOL_SP

G_OUT

Y_OUT

R

C

H

O

Y

H2O

E_OUTH_OUT

W_OUTO_OUT

RH

EWTS

BK

BK

W

1

2

3

MBV

11

YL

BL

YL

OR

OR

GY

OR YL

WT

RD

RD

GN

BL

YL

BL

BL

RD

RD

RD

BL

RD

BK

OR

BL

GY

GN

BL

GN

GN

BL

USE CLASS II FIELD WIRING

G_Out

G

C

OUT

COM

POWER

UNIT PROTECTION MODULE

STATUS

R

R

ALARM

FREEZE1

FREEZE2

COND

LPC

HPS

CC

LOCKOUT 4 2

RESET R Y

ALARM CONT PULSE

TEST YES NO

FREEZE1 15F 25F

FREEZE2 15F 25F

PUMP YES NO

GND

TO

DDC

OR

THERMOSTAT

CS

FS2

FS1

VT

CC

CMR

BN

BL

BN

BK

WT

GN/YL

A2L

Y

HPS

HPS

YL

LPS

HSL

BN

BL

example. Always refer to the wiring diagram attached to the unit.

Loading...

Loading...