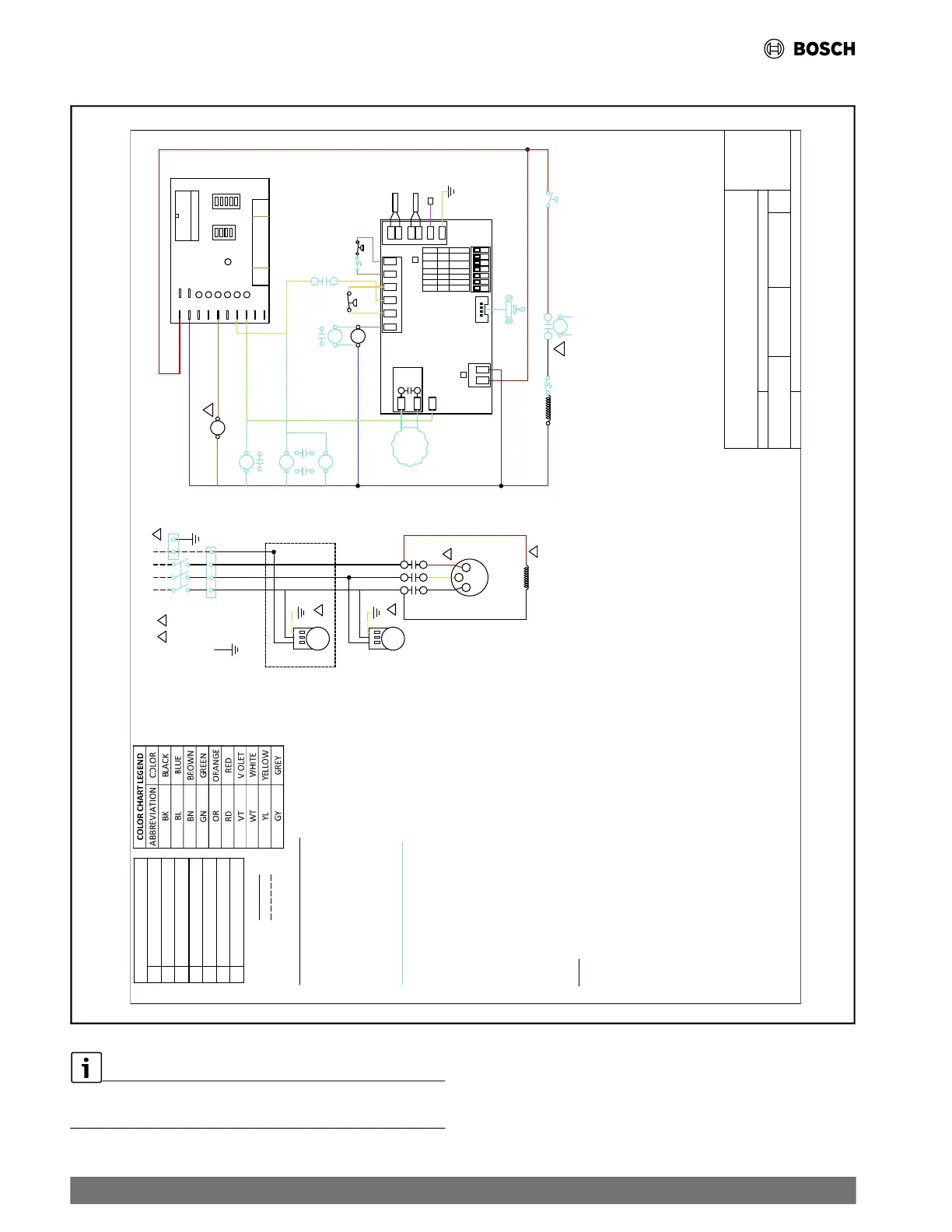

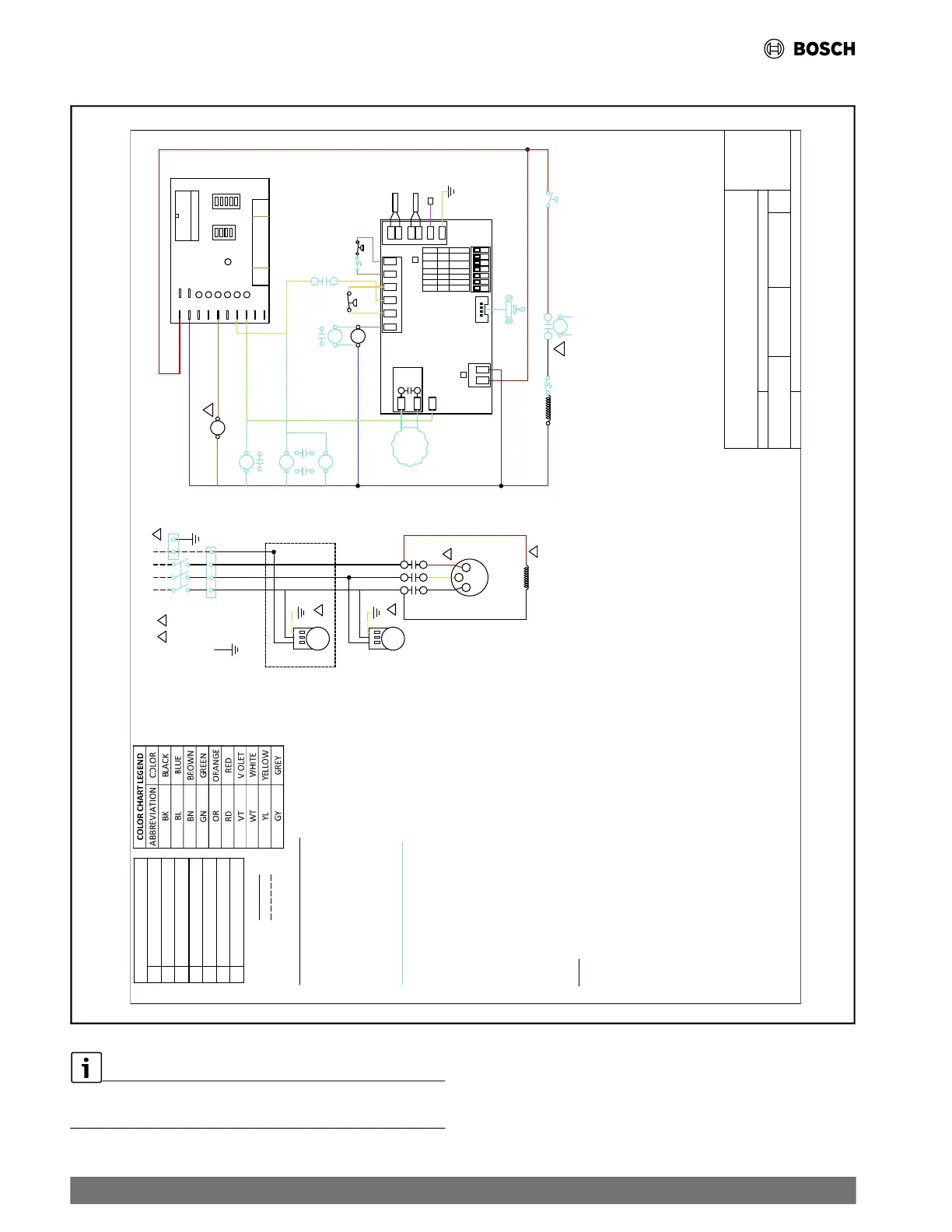

Wiring Diagrams

21.13 Single-Stage, Three-Phase, Standard Unit with CA Motor

Fig. 41 Single-Stage, Three-Phase, Standard Unit with CA Motor

DRAWN BY: DATE REV

PART No.

E-MAIL:

1 STAGE - 3 PHASE - CA MOTOR

1 1/4 THROUGH 6 TONS CAPACITY

FZA 4/8/2024 2CL311003

FACTORY WIRE

FIELD WIRE

STANDARD COMPONENTS LEGEND:

BM - BLOWER MOTOR

CAP - COMPRESSOR CAPACITOR

CC - COMPRESSOR CONTACTOR

CS - CONDENSATE SENSOR (IN DRAIN PAN)

FS - FREEZE SENSOR

HPS - HIGH PRESSURE SWITCH

LPS - LOW PRESSURE SWITCH

RV - REVERSING VALVE (HEAT PUMPS)

NOTES:

1. SEE UNIT NAME PLATE FOR ELECTRICAL RATING.

2. ALL FIELD WIRING MUST BE IN ACCORDANCE WITH

N.E.C.-N.F.P.A. #70, COPPER CONDUCTORS ONLY - CONDUCTEURS EN CUIVRE SEULEMENT.

3. 208/230V UNITS ARE FACTORY WIRED FOR 230V OPERATION. FOR 208V OPERATION,

REMOVE PRIMARY LEAD FROM 240 TERMINAL AND CONNECT IT TO 208. CAP ALL UNUSED TERMINALS.

4. FOR ALTERNATE EMS COIL VOLTAGES CONSULT FACTORY.

5. UPM-I INCLUDES BUILT IN: 270-300 SECOND RANDOM START

300 SECOND DELAY ON BREAK

120 SECOND LOW PRESSURE BYPASS

6. "TEST" DIP SWITCH REDUCES DELAYS TO 10 SEC WHEN SET TO YES. MUST BE SET TO "NO" FOR NORMAL

OPERATION.

7. "FREEZE SENSOR" ON CONDENSER WILL BE SET TO 25°F OPERATION BY DEFAULT, IF 15°F OPERATION IS REQUIRED,

MOVE DIP SWITCH SLIDER TO THE 15°F POSITION.

8. "ALARM OUTPUT" DIP SWITCH MUST BE SET TO "PULSE" IF BLINKING T-STAT SERVICE LIGHT IS DESIRED OR IF DDC

CONNECTION IS AVAILABLE. CONT FOR NON BLINKING THERMOSTAT CONNECTION.

9. DEFAULT SETTINGS FOR UPM BOARD FROM FACTORY SHOWN. ALSO SEE INSTALLATION MANUAL.

10. ALARM OUTPUT IS NORMALLY OPEN (NO) DRY CONTACT. IF 24 VAC IS NEEDED, CONNECT R FROM TERMINAL BLOCK

TO ALR-COM TERMINAL, 24VAC WILL BE SENSED ON THE ALR-OUT WHEN THE UNIT IS IN ALARM CONDITION.

OUTPUT WILL BE PULSED IF PULSE IS SELECTED.

11. REVERSING VALVE NOT PRESENT ON UNITS WITH STRAIGHT COOL.

12. TERMINAL BLOCK TB3 LOCATED IN SIDE DISCONNECT SWITCH BOX.

13. EON

MOTOR IS WIRED BETWEEN LINE AND NEUTRAL FOR 380-460VAC UNITS. FOR 208/230VAC UNITS EON MOTOR IS

WIRED BETWEEN LINES.

RV

24

EMS

AUX

C1

EM

Y1

G

O

Y2

W1

C2

H

C

R C G O Y1 Y2 W1 W2 H C

CFM ADJUST

TO ECM MOTOR

A

B

C

D

NORM

(+)

(-)

TEST

YES

HGRH

NO

CFM

R

R

LWV

OPTIONAL COMPONENTS LEGEND:

[ ] A2L - AIR TO LIQUID REFRIGERANT LEAK SENSOR

[ ] AUX - AUXILIARY RELAY

(FOR LOOP PUMP, ETC)

[ ] BMR - BLOWER MONITOR RELAY

[ ] CBR - 24V CIRCUIT BREAKER (75VA & 100VA ONLY)

[ ] CMR - COMPRESSOR MONITOR RELAY

[ ] DPS - DIFFERENTIAL PRESSURE SWITCH

[ ] DS - DISCONNECT SWITCH

[ ] EMS - ENERGY MGMT SYSTEM RELAY

[ ] HSL - HIGH TEMPERATURE SUCTION LIMIT

(WITH HOT GAS BYPASS ONLY)

[ ] LWV - LEAVING WATER VALVE

[ ] TB2 - MAIN TERMINAL BLOCK (460V UNITS ONLY)

[ ] TB3 - TERMINAL BLOCK DISCONNECT SWITCH

(460V UNITS ONLY)

BK

BK

11

YL

BL

GN

OR

OR

BL

RD

RD

BL

SEE NOTES 5 - 10

RD

YL

YL

RD

USE CLASS II FIELD WIRING

G_Out

G

C

OUT

COM

POWER

UNIT PROTECTION MODULE

STATUS

R

R

ALARM

FREEZE1

FREEZE2

COND

LPC

HPS

CC

LOCKOUT 4 2

RESET R Y

ALARM CONT PULSE

TEST YES NO

FREEZE1 15F 25F

FREEZE2 15F 25F

PUMP YES NO

GND

TO

DDC

OR

THERMOSTAT

CS

FS2

FS1

VT

CC

CMR

BN

BL

BN

BK

WT

GN/YL

A2L

Y

HPS

HPS

YL

LPS

HSL

BN

DPS

UPM STATUS LED - BLINK CODES

1

HIGH PRESSURE FAULT

2

LOW PRESSURE FAULT

3 CONDENSER FREEZE CONDITION

4 CONDENSATE OVERFLOW FAULT

5

BROWN OUT FAULT

6 EVAPORATOR FREEZE CONDITION

7 REFRIGERANT LEAKAGE

GN

BMR

BL

BL

GN

24VAC BY OTHERS

4

LWV

CBR

BL

CLASS II POWER SUPPLY

TRANSFORMER

RD

LUG

GROUND

UNIT

L1 L2

DS

BLK (COM)

TRANSFORMER

COMP

C

S

R

BM

3

21

L3

CC

T1

L1

T2

L2

T3

L3

TB2

N

TB3

BM

12

460V CONNECTION

RD

13

BK

YL

RD

WT

BK

WT

BK

RD

GN/YL

GN/YL

13

13

FOR REFERENCE ONLY Actual unit wiring may vary from this

example. Always refer to the wiring diagram attached to the unit.

84 |

CL Series Heat Pumps — 8733838716 (2024/05)

Loading...

Loading...