23MU 100 – 6721804146 (2019/10)

4 Commissioning

First make all electrical connections and then carry out the

commissioning!

▶ Observe the installation instructions for all components

and assemblies in the system.

▶ Only switch on the power supply if the coding switch is

set up.

▶ If a control unit is connected, it is recommended to start the

configuration wizard.

NOTICE:

Risk of damage to system through pump failure!

▶ Fill and vent the system before switching it on so that the

pumps do not run dry.

4.1 Setting the coding switch

Coding switch with On/Off indicator of the module and a status

display of the connected heat sources or modules:

Fig. 5 Coding switch with module status display, and a

status display of the connected heat sources or

modules

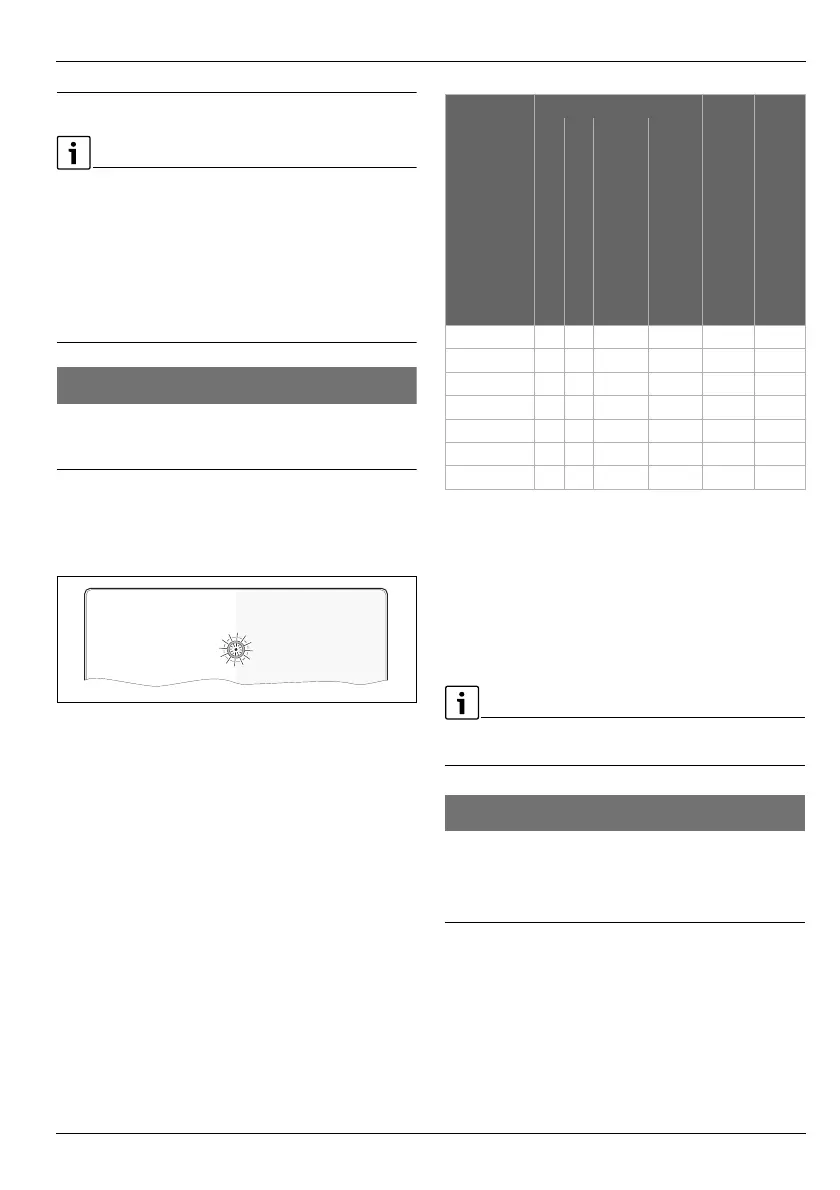

Table 7 Coding and function

4.2 Commissioning of the system and module

If a control unit is connected, start the automatic configuration

wizard.

NOTICE:

Danger of data loss in combination with MC 400

Follow the sequence during commissioning.

▶ First put heat source into operation with MU 100, then put

MC 400 into operation.

0 010 013 313-001

Coding Function of module

2nd solenoid valve activation

Fault output

Flow temperature control of the

heat source

Output control of the

heat source

Pump control via 0-10 V

Pump control via

PWM signal

0

1)

1) Off (delivered condition)

– – – – – –

1 – –

2 – –

3

2)

2) In the case of simple systems, which operate with the

standard settings, no control unit CW 400/RC310 is

necessary in positions 3 and 4. This is optional.

– – –

4

2)

– – –

5 – – – –

6-10

3)

3) Unused

– – – – – –

Loading...

Loading...