22/60 Transport and storage

Bosch Rexroth AG, A15VSO/A15VLO Series 11, RE 92801-01-B/11.2018

Only use the lifting strap ifyou are unable toachieve the required installation

position with transport using the eye bolts.

The axial piston unit can betransported suspended from aneye bolt screwed into

the drive shaft aslong asonly outward (pulling) axial forces are applied.

▶ For all female threads, use astud end from the same system ofunits and

ofthecorrect size.

▶ To do this, screw aneye bolt completely into the female thread onthe drive shaft.

The thread size isindicated inthe installation drawing.

▶ Make sure that the eye bolt can bear the total weight oftheaxial piston unit

plus20%.

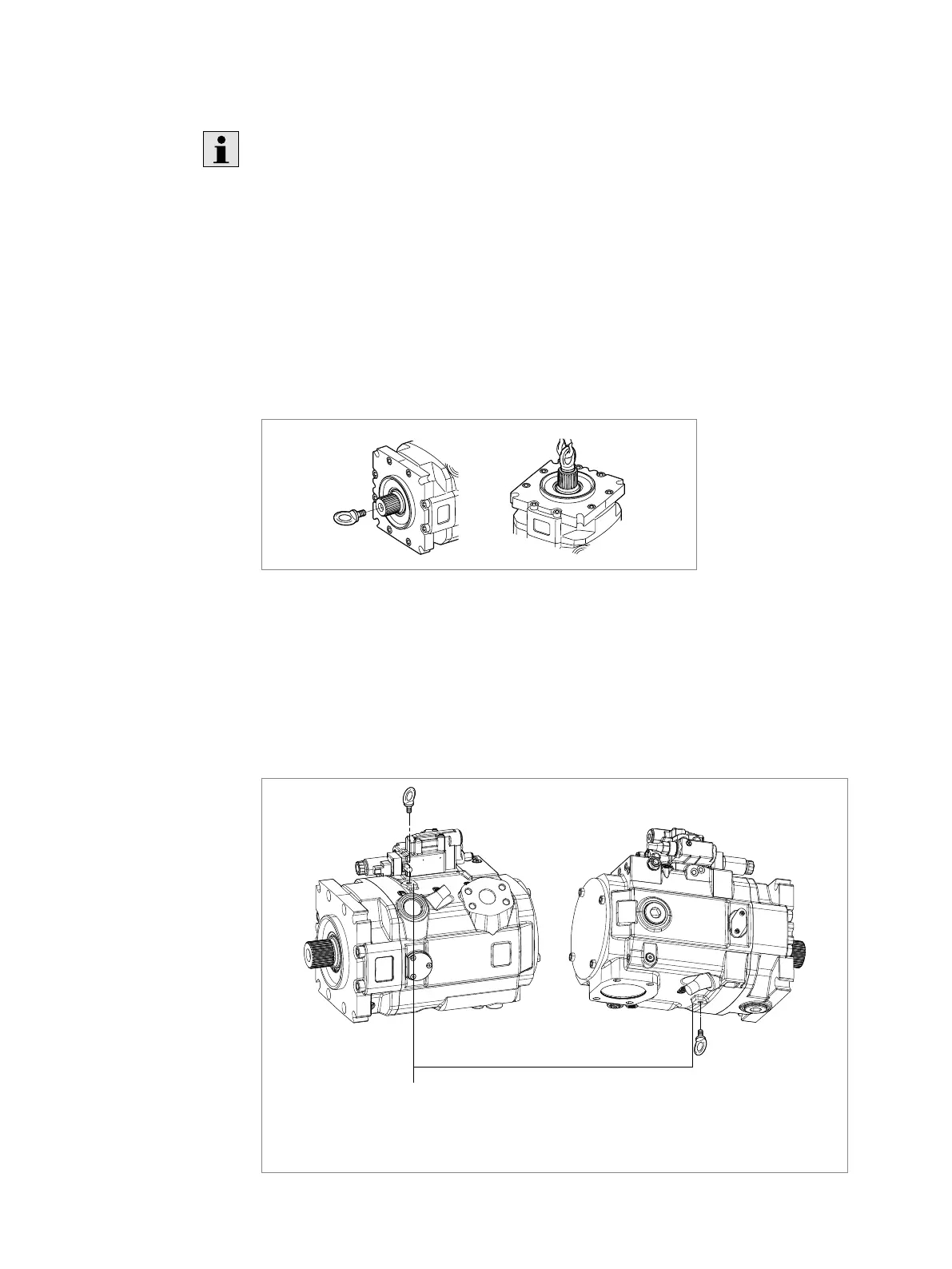

You can lift the axial piston unit asshown inFig. 5 with the eye bolt screwed into the

drive shaft.

Fig. 5: Mounting the eye bolt inthe drive shaft

▶ For all female threads, use astud end from the same system ofunits and

ofthecorrect size.

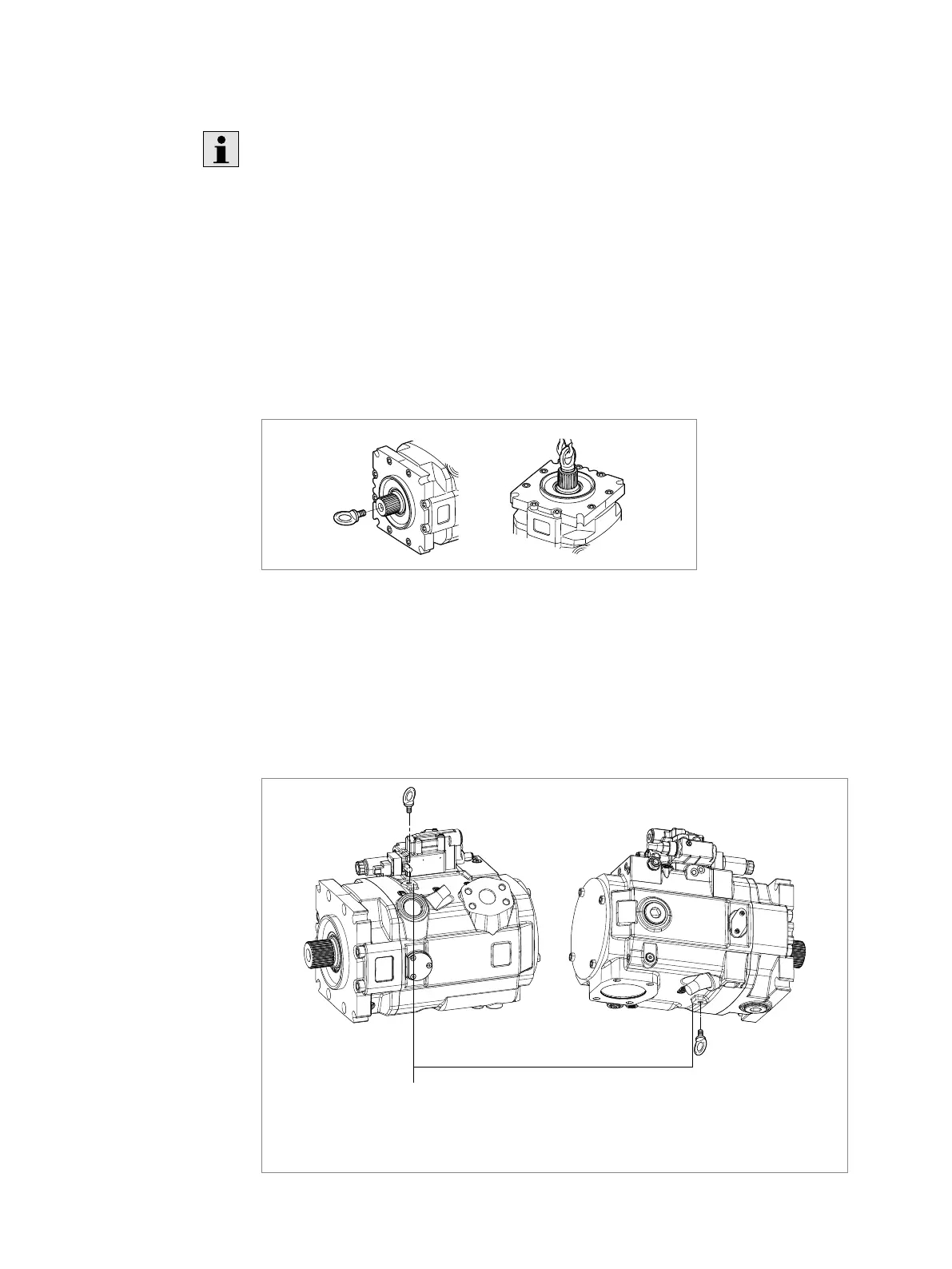

▶ Screw aneye bolt fully into the female thread inthe housing.

▶ Make sure that each eye bolt can bear the total weight oftheaxial piston unit

plus approx. 20%.

You can hoist the axial piston unit asshown inFig. 6 with the eye bolts screwed into

the housing.

Thread for eye bolt

Size175: M10x1.75; 20 deep

Sizes210 and 280: M12x1.75; 22 deep

Fig. 6: Mounting the eye bolt inthe housing, top orbottom

Transport with eye

bolt indrive shaft

(onlypermissible with

sizes110 and 145)

Transport with eye bolt

inhousing (only possible

for sizes 175, 210 and 280)

Loading...

Loading...