164/263 Bosch Rexroth AG | Tightening Technology

7.6.1 Message structure

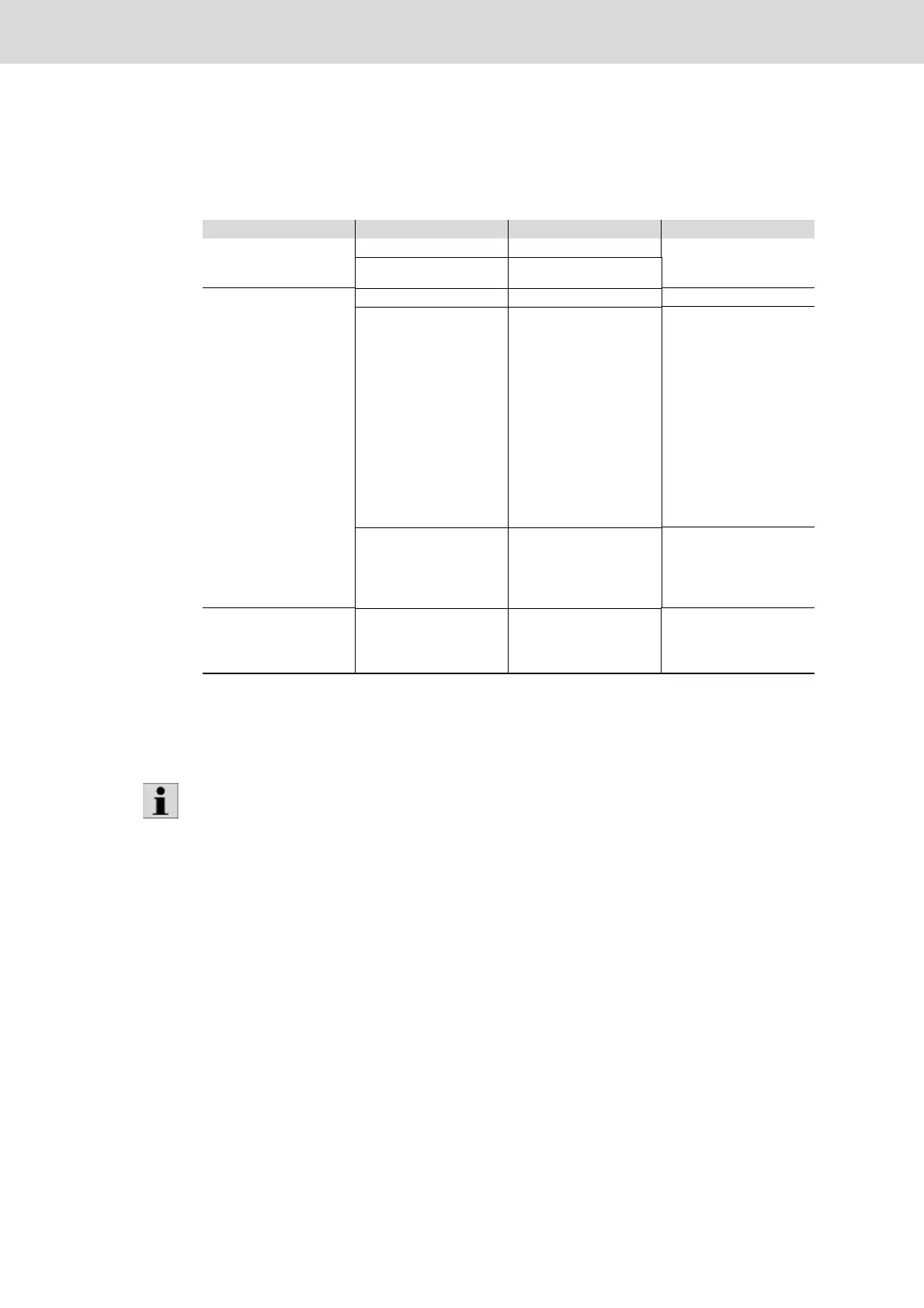

Table 7–50 shows the basic structure of a message of the Rexroth IPM Protocol.

Table 7–50: Rexroth IPM Protocol message structure

Message component Element Element description Remark

Header AFO AFO description For identification of a work

sequence (AFO) and/or

tightening position

Name AFO name

Data fields Steps Tightening steps

Actual values/

characteristics

1

1. If there is no actual value for a feature, e.g. because the corresponding monitoring function in the tightening pro-

gram is not activated, a so-called "actual dummy value" having the value -9999999 will be transferred. In the sub-

sequent evaluation on the IPM web interface, this pseudo measurement value can then be filtered out again.

Measured actual values like

– Torque (TA)

–Angle (AA)

– Gradient (GA)

–Time (TA)

– Torque threshold (SA)

Parameters belonging to

the actual values:

–TA:

TV, T+, T-, TS

– AA:

AV, A+, A--

–GA:

GV, G+, G-

–TA:

TV, T+

–SA:

without parameters

Set values/parameters Parameterized values from

KE/CS, set values and limit

values as well as parame-

ters from the database like

torque threshold set value

Parameters are clearly iden-

tified via the combination of

KE/CS, tightening channel

and tightening program

Graphs Graphs Filtered tightening result

graphs (graph filter) with

and without tightening

steps

Torque values related to data output from the Nexo cordless Wi-Fi nutrunner are rounded to two decimals

for transfer to the IPM communication partner. This may result in an error evaluation on the IPM commu-

nication partner. Please note that rounded values may result in error evaluations.