9

ENG

“EVD evolution” +030222041 - rel. 1.0 - 01.06.2008

INSTALLATION 2.

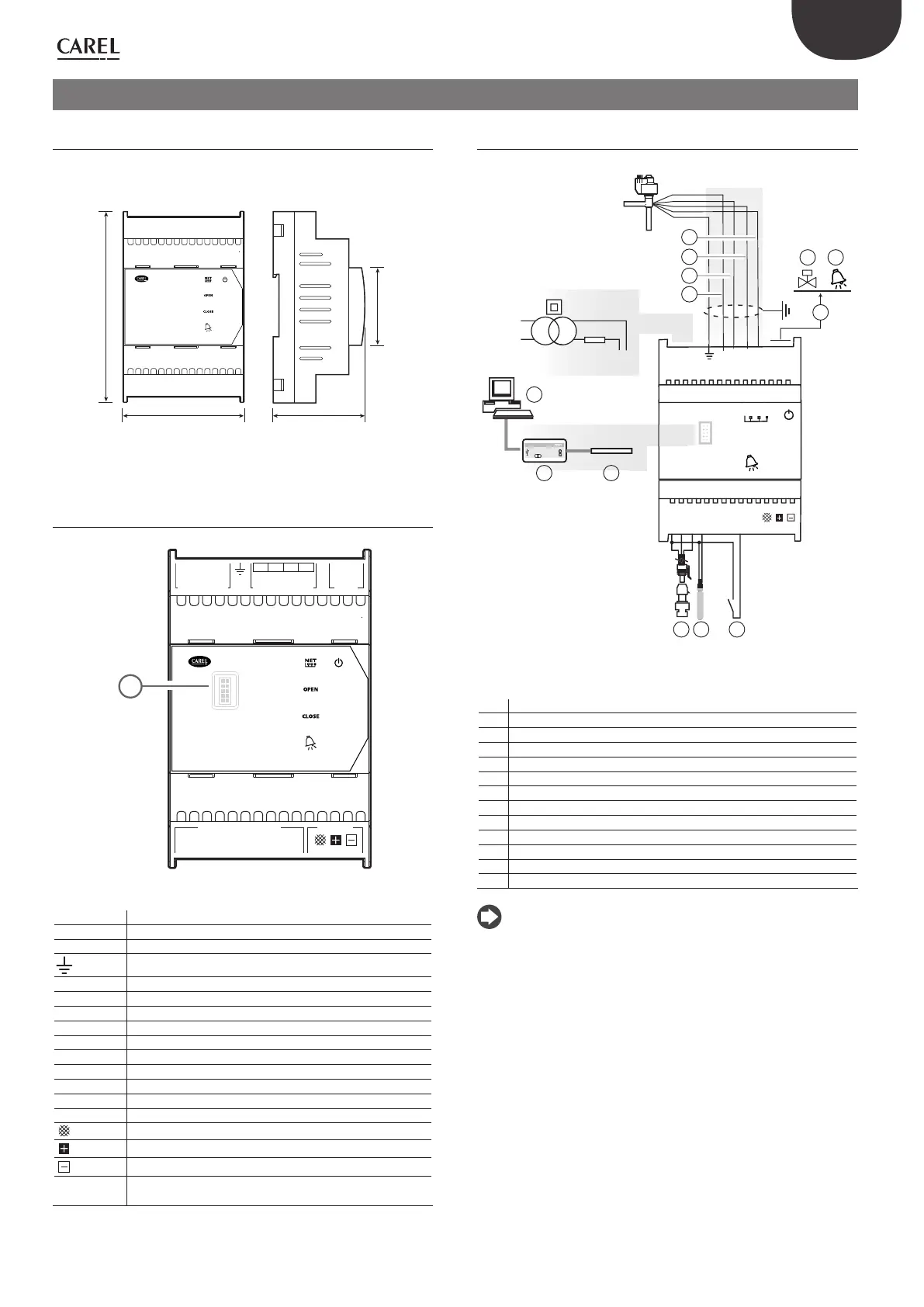

DIN rail assembly and dimensions2.1

EVD evolution is supplied with screen-printed connectors to simplify

wiring. The shield is connected with a spade terminal.

VBAT

G0

G

E

X

V connectionPower Supply Relay

NO 1

COM 1

4231

GND

V REF

S1

S2

S3

S4

DI1

DI2

Analog – Digital Input Network

GND Tx/Rx

EVD evoluti on

70 60

110

45

Fig. 2.a

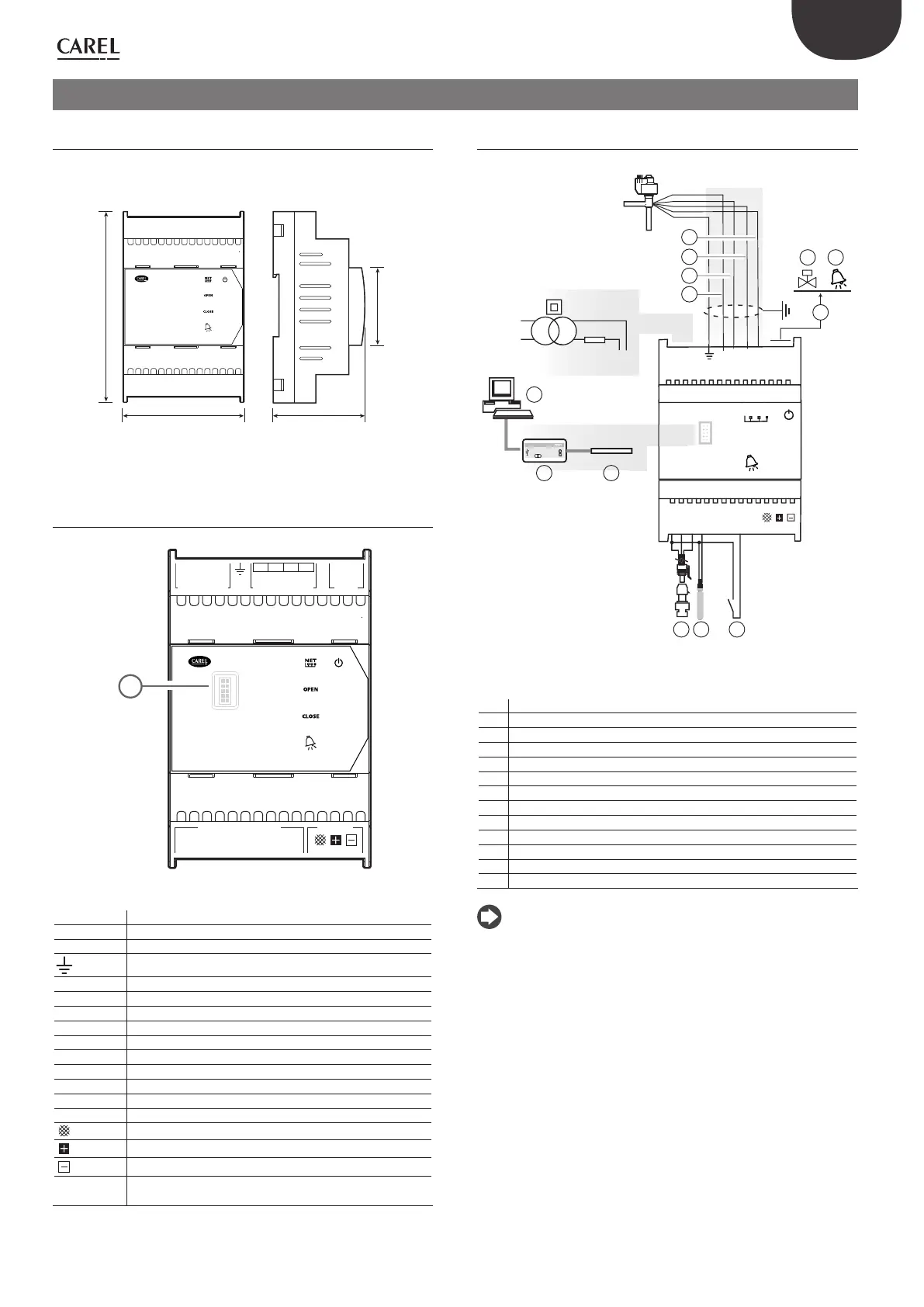

Description of the terminals2.2

VBAT

G0

G

E

X

V connectionPower Supply Relay

NO 1

COM 1

4231

GND

V REF

S1

S2

S3

S4

DI1

DI2

Analog – Digital Input Network

GND Tx/Rx

EVD evolution

aa

Fig. 2.b

Terminal Description

G, G0 Power supply

VBAT Emergency power supply

Functional earth

1,3,2,4 Stepper motor power supply

COM1, NO1 Alarm relay

GND Earth for the signals

VREF Power to active sensors

S1 Sensor 1 (pressure) or 4 to 20 mA external signal

S2 Sensor 2 (temperature) or 0 to 10 V external signal

S3 Sensor 3 (pressure)

S4 Sensor 4 (temperature)

DI1 Digital input 1

DI2 Digital input 2

Terminal for tLAN, pLAN, RS485, Modbus® connection

Terminal for tLAN, pLAN, RS485, Modbus® connection

Terminal for pLAN, RS485, Modbus® connection

aa porta seriale di servizio (rimuovere il coperchio per potervi

accedere)

Tab. 2.a

Connection diagram - superheat control2.3

G

G0

G

G0

VBAT

COM1

NO1

1

3

2 4

NET

OPEN

CLOSE

Tx/RxGND

DI1

S4

S3

S2

S1

GND

DI2

VREF

2 AT

24 Vac

230 Vac

30VA

shield

EVD4

PC

EVD4 service USB adapter

4

S

4

2

3

CAREL E

X

V

1

6 7

8 9 10

11

12 13

5

Fig. 2.c

Key:

1 green

2 yellow

3 brown

4 white

5 personal computer for confi guration

6 USB/tLAN converter

7 adapter

8 ratiometric pressure transducer - evaporation pressure

9 NTC suction temperature

10 digital input 1 to enable control

11 free contact (up to 230 Vac)

12 solenoid valve

13 alarm signal

Note:

the use of the driver for the superheat control requires the use of the •

evaporation pressure sensor S1 and the suction temperature sensor S2,

which will be fi tted after the evaporator, and digital input 1 to enable

control. As an alternative to digital input 1, control can be enabled via

remote signal (tLAN, pLAN, RS485). For the positioning of the sensors

relating to other applications, see the chapter on “Control”;

inputs S1, S2 are programmable and the connection to the terminals •

depends on the setting of the parameters. See the chapters on

“Commissioning” and “Functions”;

pressure sensor S1 in the diagram is ratiometric. See the general •

connection diagram for the other electronic sensors, 4 to 20 mA or

combined.

Loading...

Loading...