18

ENG

“EVD evolution” +030222041 - rel. 1.0 - 01.06.2008

CONTROL5.

Superheat control5.2

The primary purpose of the electronic valve is ensure that the flow-rate

of refrigerant that flows through the nozzle corresponds to the flow-rate

required by the compressor. In this way, the evaporation process will

take place along the entire length of the evaporator and there will be

no liquid at the outlet and consequently in the branch that runs to the

compressor.

As liquid is not compressible, it may cause damage to the compressor

and even breakage if the quantity is considerable and the situation lasts

some time.

Superheat control

The parameter that the control of the electronic valve is based on is the

superheat temperature, which effectively tells whether or not there is

liquid at the end of the evaporator.

The superheat temperature is calculated as the difference between:

superheated gas temperature (measured by a temperature sensor located

at the end of the evaporator) and the saturated evaporation temperature

(calculated based on the reading of a pressure transducer located at the

end of the evaporator and using the Tsat(P) conversion curve for each

refrigerant).

Superheat= Superheated gas temperature(*) – Saturated evaporation

temperature

(*) suction

If the superheat temperature is high it means that the evaporation process

is completed well before the end of the evaporator, and therefore flow-

rate of refrigerant through the valve is insufficient. This causes a reduction

in cooling efficiency due to the failure to exploit part of the evaporator.

The valve must therefore be opened further.

Vice-versa, if the superheat temperature is low it means that the

evaporation process has not concluded at the end of the evaporator

and a certain quantity of liquid will still be present at the inlet to the

compressor. The valve must therefore be closed further. The operating

range of the superheat temperature is limited at the lower end: if the

flow-rate through the valve is excessive the superheat measured will be

near 0 K. This indicates the presence of liquid, even if the percentage

of this relative to the gas cannot be quantified. There is therefore un

undetermined risk to the compressor that must be avoided. Moreover, a

high superheat temperature as mentioned corresponds to an insufficient

flow-rate of refrigerant.

The superheat temperature must therefore always be greater than 0 K

and have a minimum stable value allowed by the valve-unit system. A

low superheat temperature in fact corresponds to a situation of probable

instability due to the turbulent evaporation process approaching the

measurement point of the sensors. The expansion valve must therefore

be controlled with extreme precision and a reaction capacity around

the superheat set point, which will almost always vary from 3 to 14 K.

Set point values outside of this range are quite infrequent and relate to

special applications.

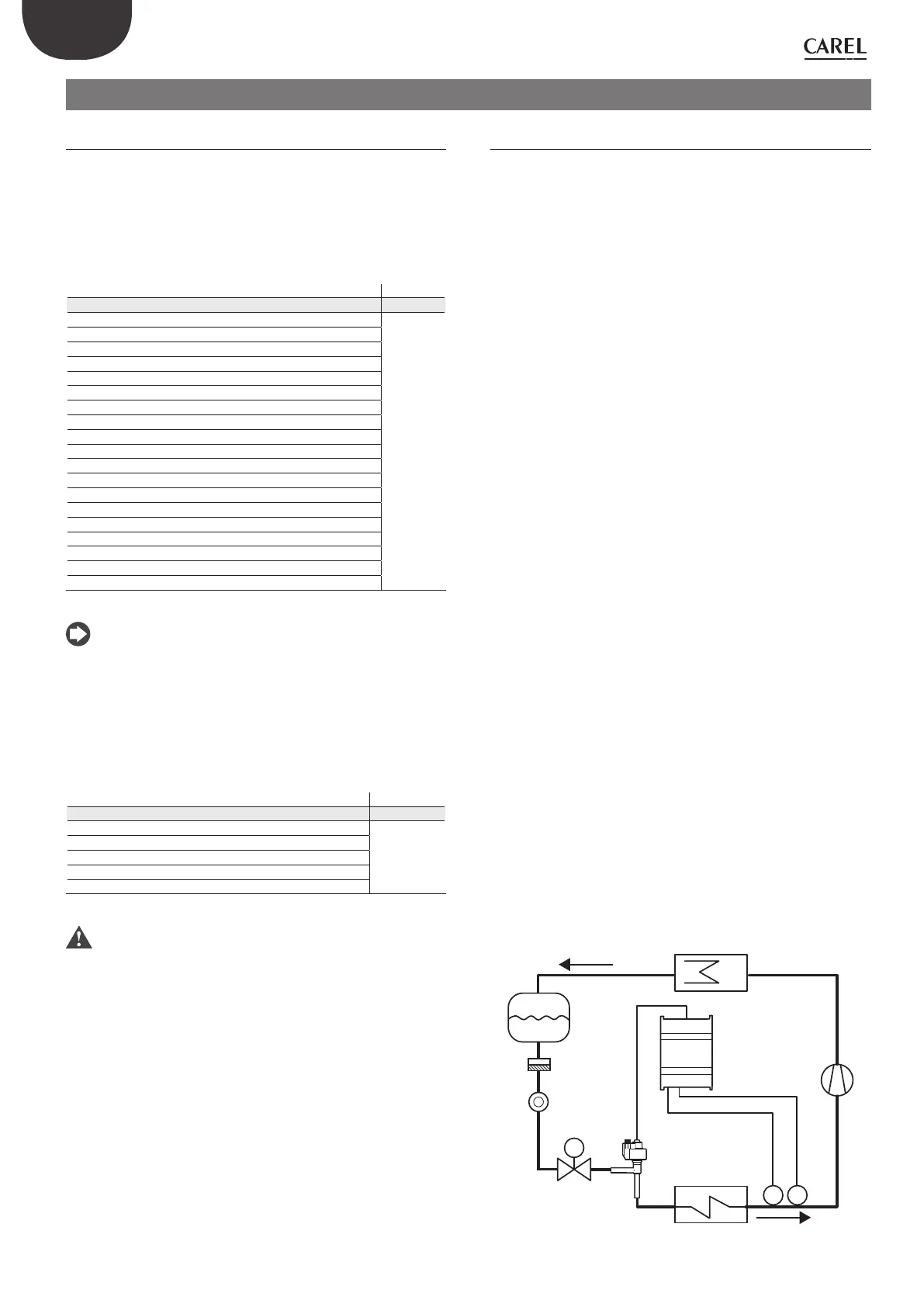

S2

S1

EVD

evolution

P

E

V

S

F

L

M

T

CP

C

EEV

Fig. 5.a

Main and auxiliary control5.1

EVD evolution features two types of control

main;•

auxiliary.•

Main control is always active, while auxiliary control can be activated

by parameter. Main control defines the operating mode of the driver.

The first 10 settings refer to superheat control, the others are so-called

“special” settings and are pressure or temperature settings or depend on

a control signal from an external controller.

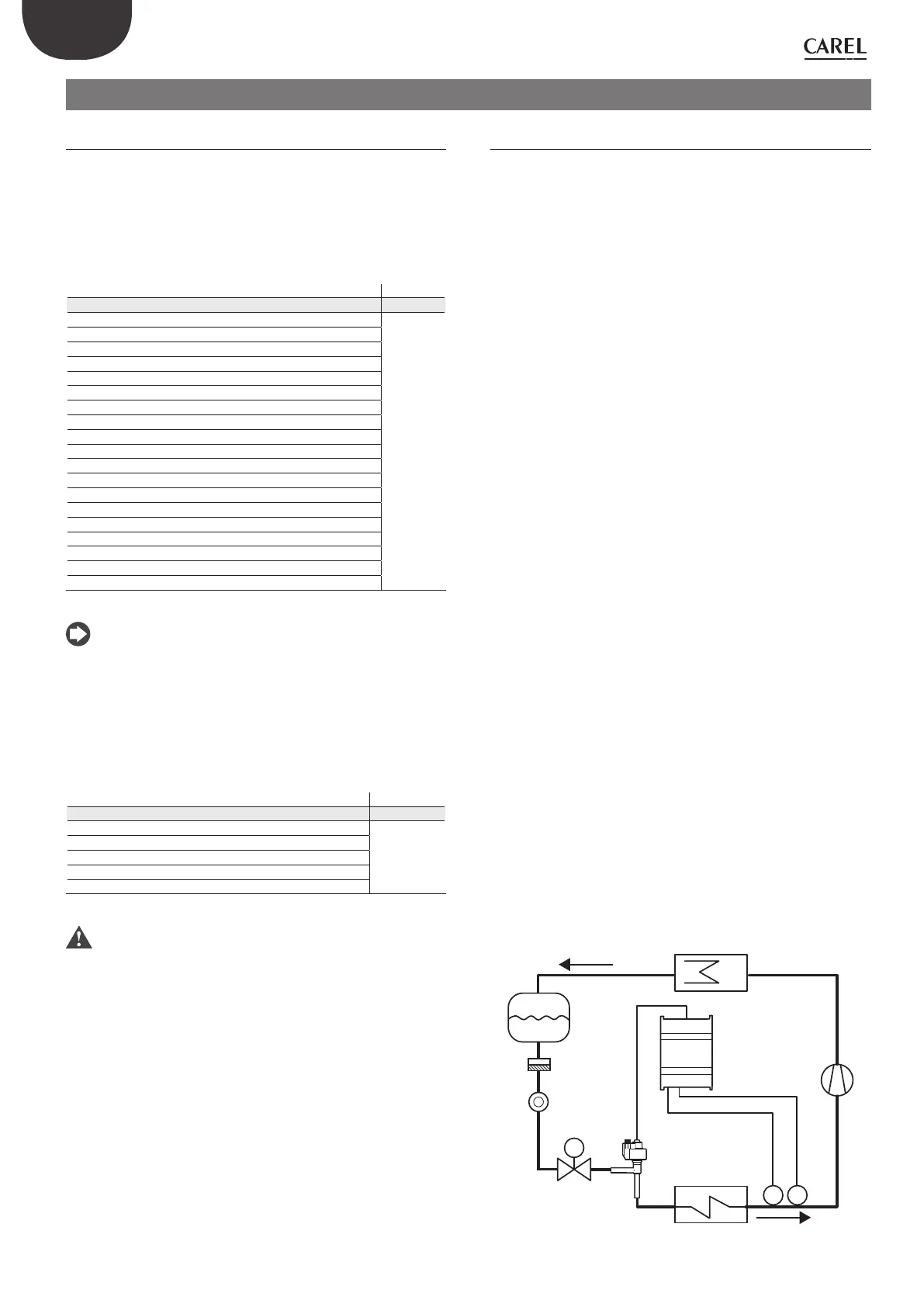

Parameter/description Def.

Configuration

Main control multiplexed

cabinet/

cold room

Superheat control

multiplexed cabinet/cold room

cabinet/cold room with on-board compressor

“perturbed” cabinet/cold room

cabinet/cold room with sub-critical CO

2

R404A condenser for sub-critical CO

2

air-conditioner/chiller with plate heat exchanger

air-conditioner/chiller with tube bundle heat exchanger

air-conditioner/chiller with finned coil heat exchanger

air-conditioner/chiller with variable cooling capacity

“perturbed” air-conditioner/chiller

Special control

EPR back-pressure

hot gas bypass by pressure

hot gas bypass by temperature

transcritical CO

2

gas cooler

analogue positioner (4 to 20 mA)

analogue positioner (0 to 10 V)

Tab. 5.a

Note:

R404A condensers with subcritical CO•

2

refer to superheat control for

valves installed in cascading systems where the flow of R404A (or other

refrigerant) in an exchanger acting as the CO

2

condenser needs to be

controlled;

“perturbed” cabinet/cold room or air-conditioner/chiller refer to units •

that momentarily or permanently operate with swinging condensing

or evaporation pressure.

Auxiliary control features the following settings:

Parameter/description Def.

Configuration

Auxiliary control Disabled

Disabled

High condensing temperature protection on S3

Modulating thermostat on S4

Backup sensors on S3 & S4

Tab. 5.b

Important: the “High condensing temperature protection” and

“Modulating thermostat” auxiliary settings can only be enabled if the

main control is superheat control (first 10 settings). On the other hand,

“Backup sensors on S3 & S4” can always be activated, once the related

sensors have been connected.

The following paragraphs explain all the types of control that can be set

on EVD evolution.

Loading...

Loading...