28

ENG

“EVD evolution” +030222041 - rel. 1.0 - 01.06.2008

PROTECTORS7.

These are additional functions that are activated in specific situations that

are potentially dangerous for the unit being controlled. They feature an

integral action, that is, the action increases gradually when moving away

from the activation threshold. They may add to or overlap (disabling)

normal PID superheat control. By separating the management of

these functions from PID control, the parameters can be set separately,

allowing, for example, normal control that is less reactive yet much

faster in responding when exceeding the activation limits of one of the

protectors.

Protectors7.1

The protectors are 4:

LowSH, low superheat;•

LOP, low evaporation temperature;•

MOP, high evaporation temperature;•

HiTcond, high condensing temperature.•

Note: The HITCond protection requires an additional sensor (S3) to

those normally used, either installed on the driver, or connected via tLAN

or pLAN to a controller.

The protectors have the following main features:

activation threshold: depending on the operating conditions of the

•

controlled unit, this is set in Service programming mode;

integration time, which determines the intensity (if set to 0, the •

protector is disabled): set automatically based on the type of main

control;

alarm, with activation threshold (the same as the protector) and delay •

(if set to 0 disables the alarm signal).

Note: The alarm signal is independent from the effectiveness of the

protector, and only signals that the corresponding threshold has been

exceeded. If a protector is disabled (null integration time), the relative

alarm signal is also disabled.

Each protector is affected by the proportional gain parameter (K) for the

PID superheat control. The higher the value of K, the more intense the

reaction of the protector will be.

Characteristics of the protectors

Protection Reaction Reset

LowSH Intense closing Immediate

LOP Intense opening Immediate

MOP Moderate closing Controlled

HiTcond Moderate closing Controlled

Tab. 7.a

Reaction: summary description of the type of action in controlling the

valve.

Reset: summary description of the type of reset following the activation

of the protector. Reset is controlled to avoid swings around the activation

threshold or immediate reactivation of the protector.

LowSH (low superheat)

The protector is activated so as to prevent the return of liquid to the

compressor due to excessively low superheat valves from.

Parameter/description Def. Min. Max. UOM

CONTROL

LowSH protection: threshold 5 -40 (-72) set point

superheat

K (°R)

LowSH protection: integration

time

15 0 800 s

ALARM CONFIGURATION

Low superheat alarm delay

(LowSH) (0= alarm disabled)

300 0 18000 s

Tab. 7.b

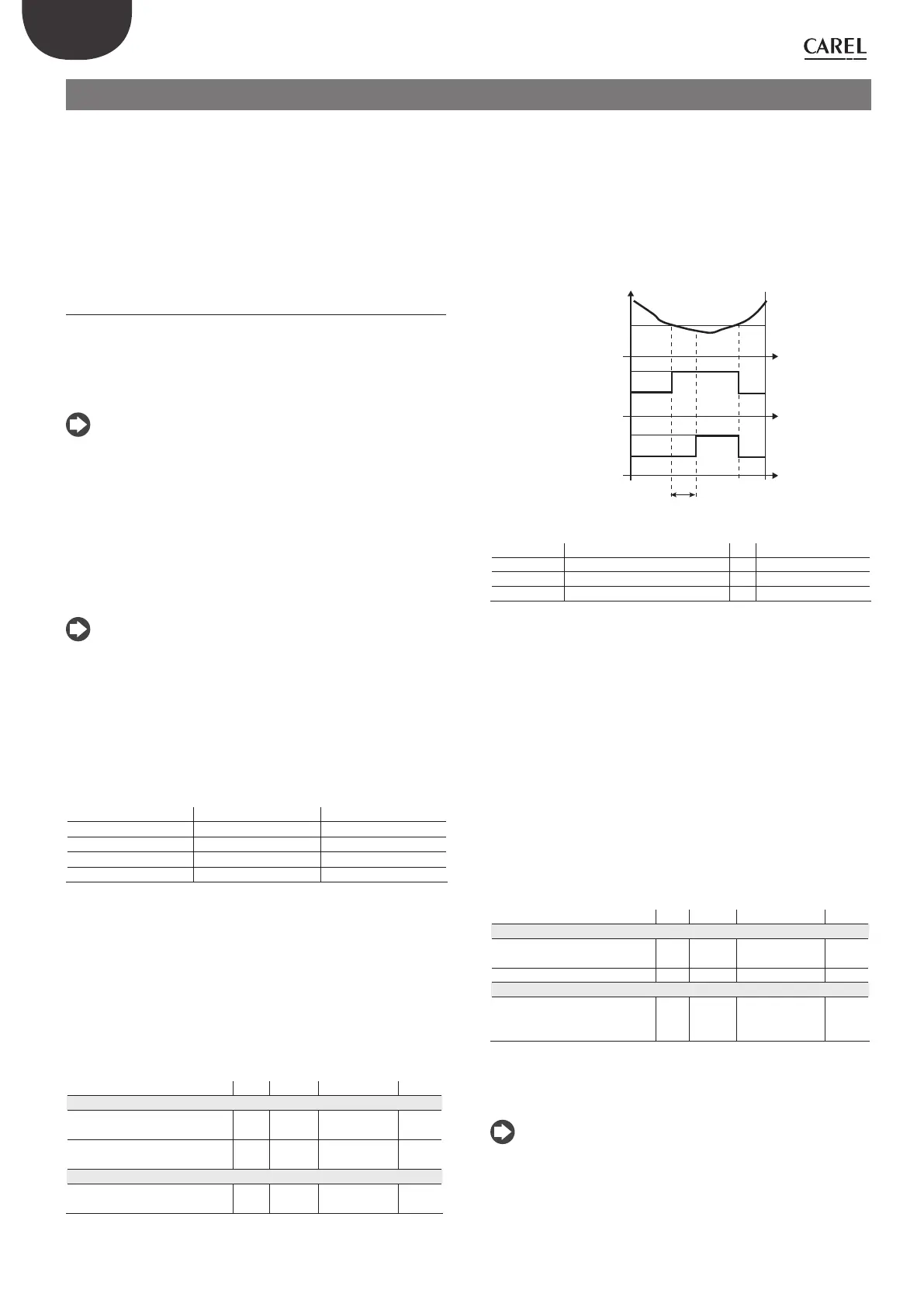

When the superheat value falls below the threshold, the system enters

low superheat status, and the intensity with which the valve is closed is

increased: the more the superheat falls below the threshold, the more

intensely the valve will close. The LowSH threshold, must be less than

or equal to the superheat set point. The low superheat integration time

indicates the intensity of the action: the lower the value, the more intense

the action.

The integration time is set automatically based on the type of main

control.

t

t

t

OFF

ON

R

OFF

ON

Low_SH

Low_SH_TH

SH

D

B

Fig. 7.a

Key:

SH Superheat A Alarm

Low_SH_TH Low_SH protection threshold D Alarm delay

Low_SH Low_SH protection t Time

B Automatic alarm reset

LOP (low evaporation pressure)

LOP= Low Operating Pressure

The LOP protection threshold is applied as a saturated evaporation

temperature value so that it can be easily compared against the technical

specifications supplied by the manufacturers of the compressors. The

protector is activated so as to prevent too low evaporation temperatures

from stopping the compressor due to the activation of the low pressure

switch. The protector is very useful in units with compressors on board

(especially multi-stage), where when starting or increasing capacity the

evaporation temperature tends to drop suddenly.

When the evaporation temperature falls below the low evaporation

temperature threshold, the system enters LOP status and is the intensity

with which the valve is opened is increased. The further the temperature

falls below the threshold, the more intensely the valve will open. The

integration time indicates the intensity of the action: the lower the value,

the more intense the action.

Parameter/description Def. Min. Max. UOM

CONTROL

LOP protection: threshold -50 -60 (-72) Protection MOP:

threshold

°C (°F)

LOP protection: integration time 0 0 800 s

ALARM CONFIGURATION

Low evaporation temperature

alarm delay (LOP)

(0= alarm disabled)

300 0 18000 s

Tab. 7.c

The integration time is set automatically based on the type of main

control.

Note:

the LOP threshold must be lower then the rated evaporation •

temperature of the unit, otherwise it would be activated unnecessarily,

and greater than the calibration of the low pressure switch, otherwise

it would be useless. As an initial approximation it can be set to a value

exactly half-way between the two limits indicated;

the protector has no purpose in multiplexed systems (showcases) •

where the evaporation is kept constant and the status of the individual

Loading...

Loading...