22

ENG

“EVD evolution” +030222041 - rel. 1.0 - 01.06.2008

Auxiliary control 5.4

Auxiliary control can be activated at the same time as main control, and

uses the sensors connected to inputs S3 and/or S4.

Parameter/description Def.

CONFIGURATION

Auxiliary control:

Disabled; High condensing temperature protection on S3;

Modulating thermostat on S4; Backup sensors on S3 & S4

Disabled

Tab. 5.h

For the high condensing temperature protection (only available with

superheat control), an additional pressure sensor is connected to S3 that

measures the condensing pressure.

For the modulating thermostat function (only available with superheat

control), an additional temperature sensor is connected to S4 that

measures the temperature on used to perform temperature control (see

the corresponding paragraph).

The last option (available always) requires the installation of both sensors

S3 & S4, the first pressure and the second temperature.

Note: if only one backup sensor is fitted, under the manufacture

parameters, the sensor thresholds and alarm management can be set

separately.

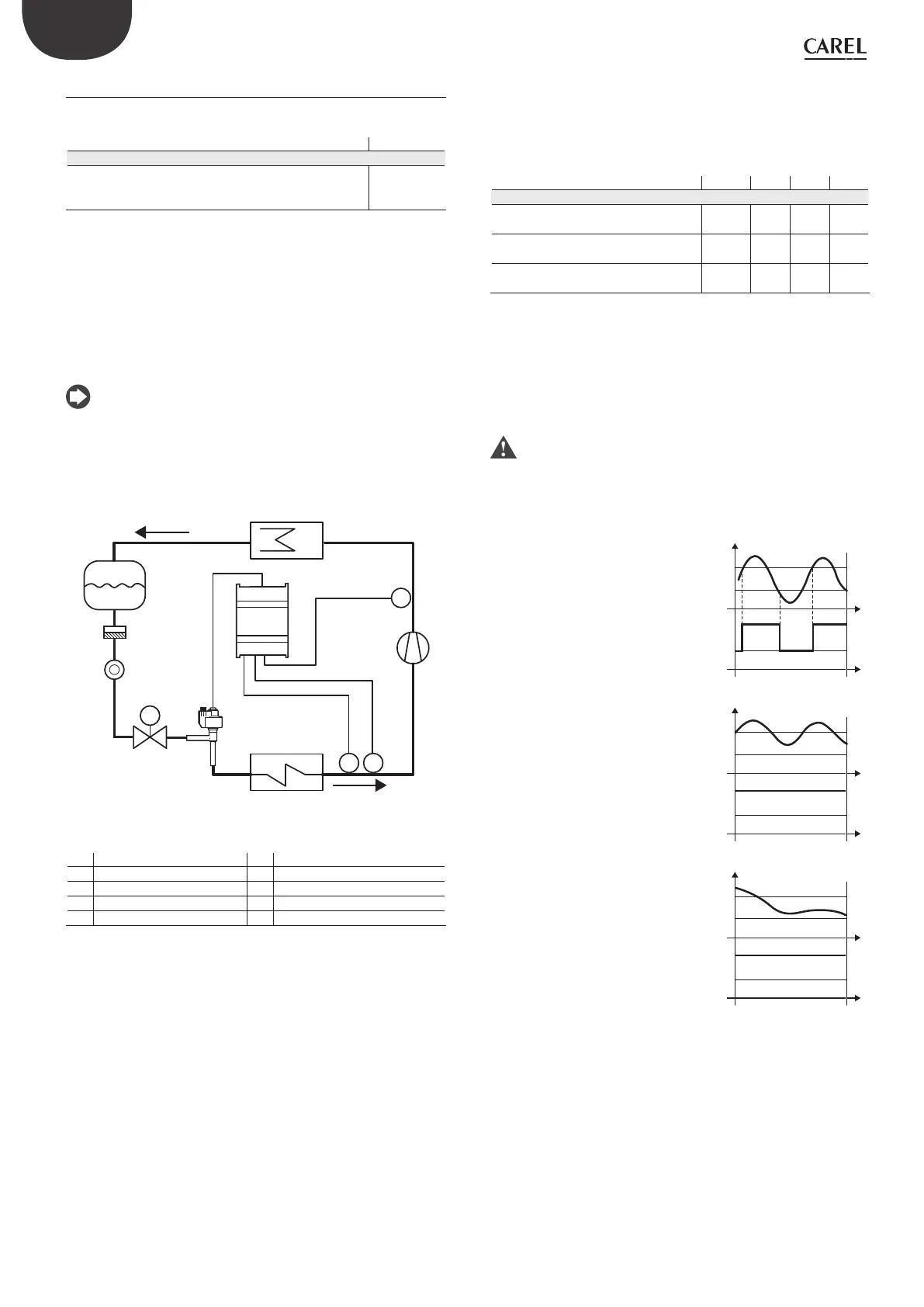

HITCond protection (high condensing temperature)

The functional diagram is shown below.

S2

S3

S1

EVD

evolution

P

P

E

V

S

F

L

M

T

CP

C

EEV

Fig. 5.h

Key:

CP Compressor EEV Electronic expansion valve

C Condenser V Solenoid valve

L Liquid receiver E Evaporator

F Dewatering filter P Pressure sensor (transducer)

S Liquid indicator T Temperature sensor

For the wiring, see paragraph 2.7 “General connection diagram”.

As already mentioned, the HITCond protection can only be enabled if the

control measures the condensing pressure/temperature, and responds

moderately by closing the valve in the event where the condensing

temperature reaches excessive values, to prevent the compressor from

shutting down due to high pressure. The condensing pressure sensor

must be connected to input S3.

Modulating thermostat

This function is used, by connecting a temperature sensor to input

S4, to modulate the opening of the electronic valve so as to limit the

lowering of the temperature read and consequently reach the control

set point. This is useful in applications such as the multiplexed cabinets

to avoid the typical swings in air temperature due to the ON/OFF control

(thermostatic) of the solenoid valve. A temperature sensor must be

connected to input S4, located in a similar position to the one used for

the traditional temperature control of the cabinet. In practice, the close

the controlled temperature gets to the set point, the more the control

function decreases the cooling capacity of the evaporator by closing the

expansion valve.

By correctly setting the related parameters (see below), a very stable

cabinet temperature can be achieved around the set point, without ever

closing the solenoid valve. The function is defined by three parameters:

set point, differential and offset.

Parameter/description Def. Min. Max. UOM

SPECIAL

Modulating thermostat: set point 0 -60

(-76)

200

(392)

°C (°F)

Modulating thermostat: differential 0,1 0,1

(0,2)

100

(180)

°C (°F)

Modulating thermostat: superheat set

point offset (0= function disabled)

0 0 (0) 100

(180)

K (°R)

Tab. 5.i

The first two should have values similar to those set on the controller for

the cabinet or utility whose temperature is being modulated.

The offset, on the other hand, defines the intensity in closing the valve as

the temperature decreases: the greater the offset, the more the valve will

be modulated. The function is only active in a temperature band between

the set point and the set point plus the differential.

Important: the “Modulating thermostat” function should not be

used on stand-alone refrigeration units, but only in centralised systems.

In fact, in the former case closing the valve would cause a lowering of the

pressure and consequently shut down the compressor.

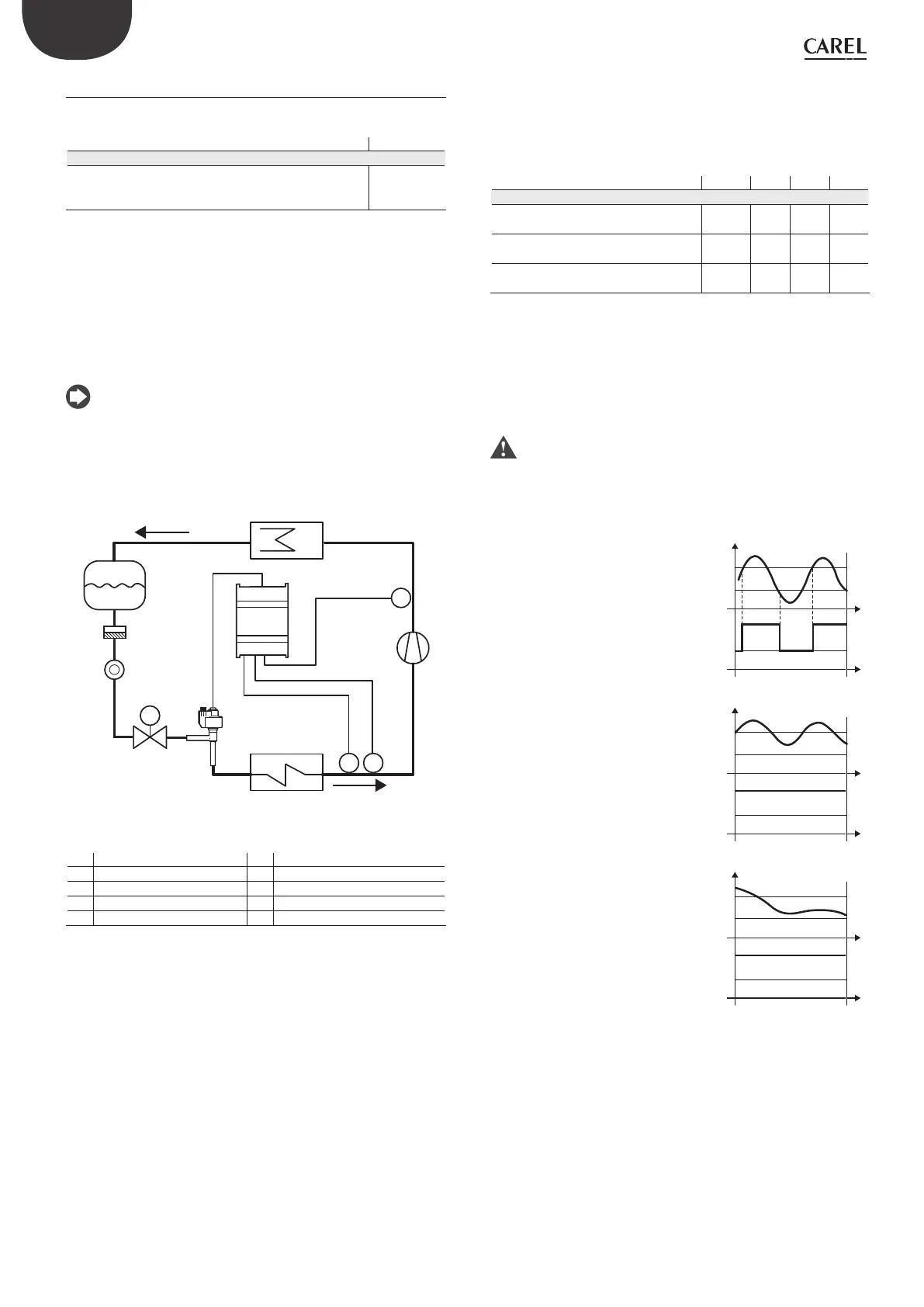

Examples of operation:

offset too low (or function 1.

disabled)

S4

t

t

OFF

set point

set point + diff

ON

F

offset too high2.

S4

t

t

OFF

set point

set point + diff

ON

F

offset correct3.

S4

t

t

OFF

set point

set point + diff

ON

F

Key:

diff= differential

F= modulating thermostat function

S4= temperature

Loading...

Loading...