669224-R5

ROUBLESHOOTING

T

19

CL2225.eps

4.4 Attachment Troubleshooting

Therearevepotentialproblemareasthatcouldaffectthe

CLAMPfunction.

• Incorrectloadhandling.RefertotheOperator'sGuide

forsuggestedprocedures.

• Insufcienthydraulicpressurefromthelifttruck.

• Externalleaks.

• Warnordefectivecartridgevalvesorcylinderseals.

• Defectivesolenoidcoilorvalve,ifequipped.

4.4-1 Clamp Circuit Pressure Test

1 Checkthepressuresuppliedbythetruckatthecarriage

hoseterminalorjunctionblock.Refertothetruck

servicemanual,asneeded.Pressuremustbewithin

therangeshowninSpecications,Section6.1. TRUCK

PRESSURE MUST NOT EXCEED 2300 psi (160 bar).

2 Checktheowvolumeatthecarriagehoseterminal.

FlowmustbewithintherangeshowninSpecications,

Section6.1.

3 Attachments with Solenoid Adaption –Pressthe

auxiliaryvalvecontrolknobbutton.Listenfora'click'at

thesolenoidvalve.Ifthesolenoiddoesnot'click'when

thebuttonispressed,checktheelectricalwiringand

solenoidcoil.

4 Checkforexternalleaks.Startthetruck.Closethe

armsfully.HoldtheCLAMPcontrolhandleintheclamp

positionforafewseconds.

5 Returnthehandletoneutral.Inspectallttings,lines,

andthecylindersforleaks.Iftherearenoleaks,

proceedwiththepressuretest.

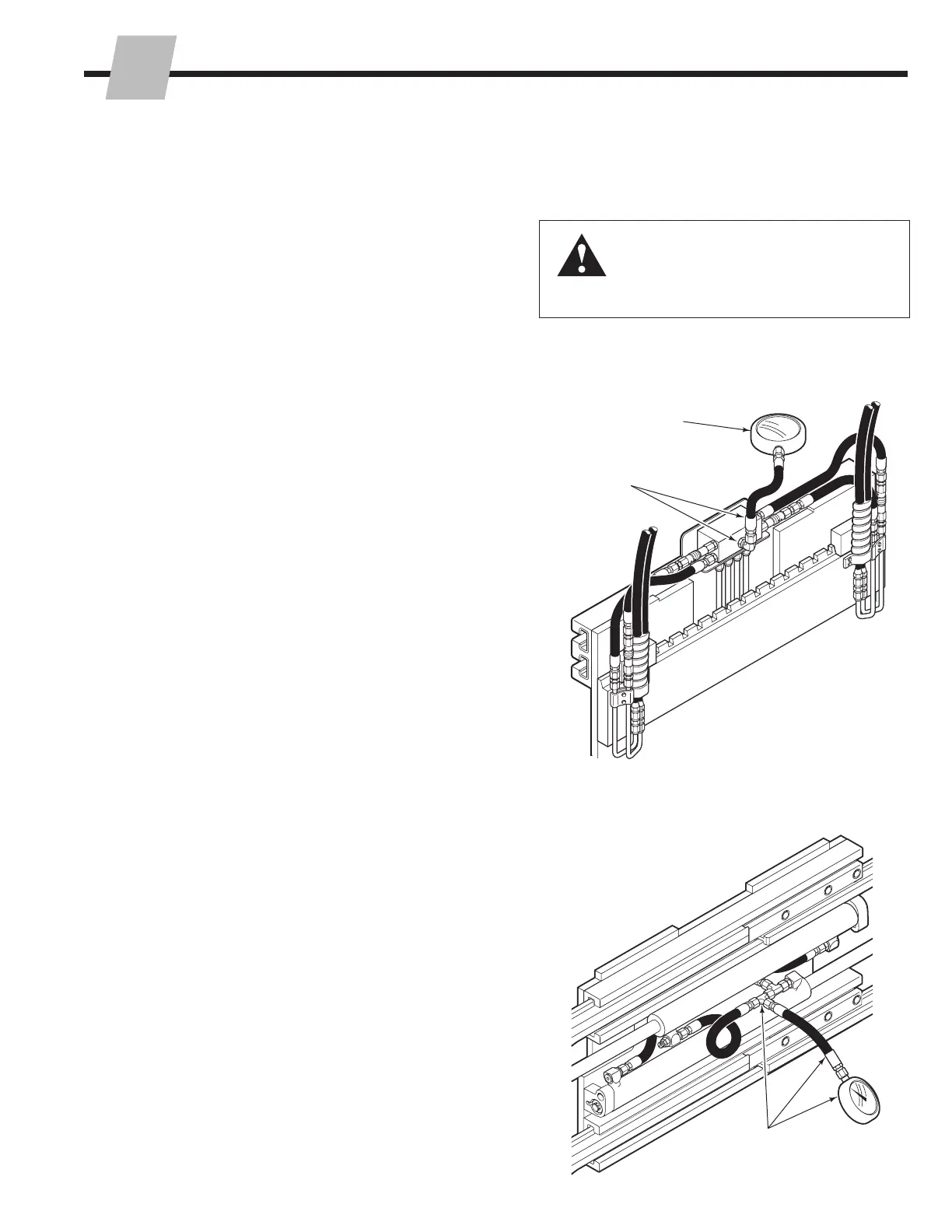

6 Top Mount Valves –Installthepressuregaugeand

hoseassemblyinthevalvetestportmarked'G',located

onthebackofthevalvebody.

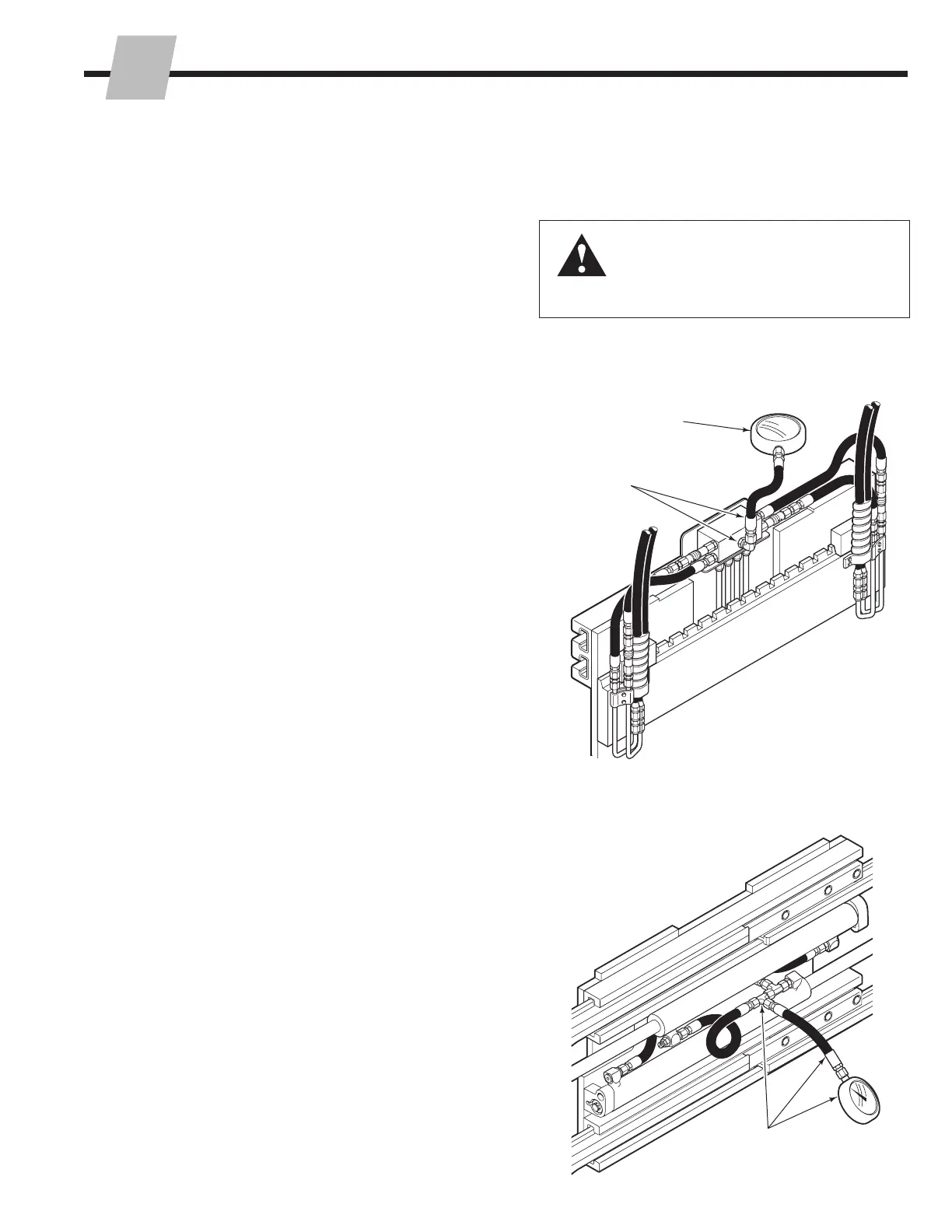

Center Mount Valves – Removethebumper.Installa

teetting,hoseandgaugebetweenthecylinderrod

endsupplyhoseandteetting,asshown.

7 Startthetruck.Closethearmsfully.HoldtheCLAMP

controlhandleintheclamppositionforafewseconds.

8 Returnthehandletoneutral.Watchthegaugepressure

reading.

• Ifthepressure does not dropmorethan150psi

(10bar)initiallyandanadditionaldropdoesnot

exceed25psi(2bar)perminute,theproblemisnot

hydraulic.RefertoSection4.1-3.

• Ifthe pressure dropsmorethan150psi(10bar)

initiallyandadditionaldropexceeds25psi(2bar)

perminute,proceedwiththetroubleshootingcheck

listtoisolatethefaultycomponent.

IMPORTANT:Beforeremovingthepressuregauge,

momentarilyactuateCLAMPopencircuit.Thiswill

relievepressuretrappedbythecheckvalveinthe

CLAMPcircuit.

WARNING:Beforeremovinghydraulic

linesorcomponents,relievepressureinthe

hydraulicsystem.Turntruckoffandopen

thetruckauxiliarycontrolvalve(s)several

timesinbothdirections.

Installgaugeand

hoseinport'G'

90°tting

andhose

Installteetting,

hoseandgauge

Top Mount Valves

Center Mount Valves

CL2226.eps

Loading...

Loading...