669224-R5

ERVICE

S

29

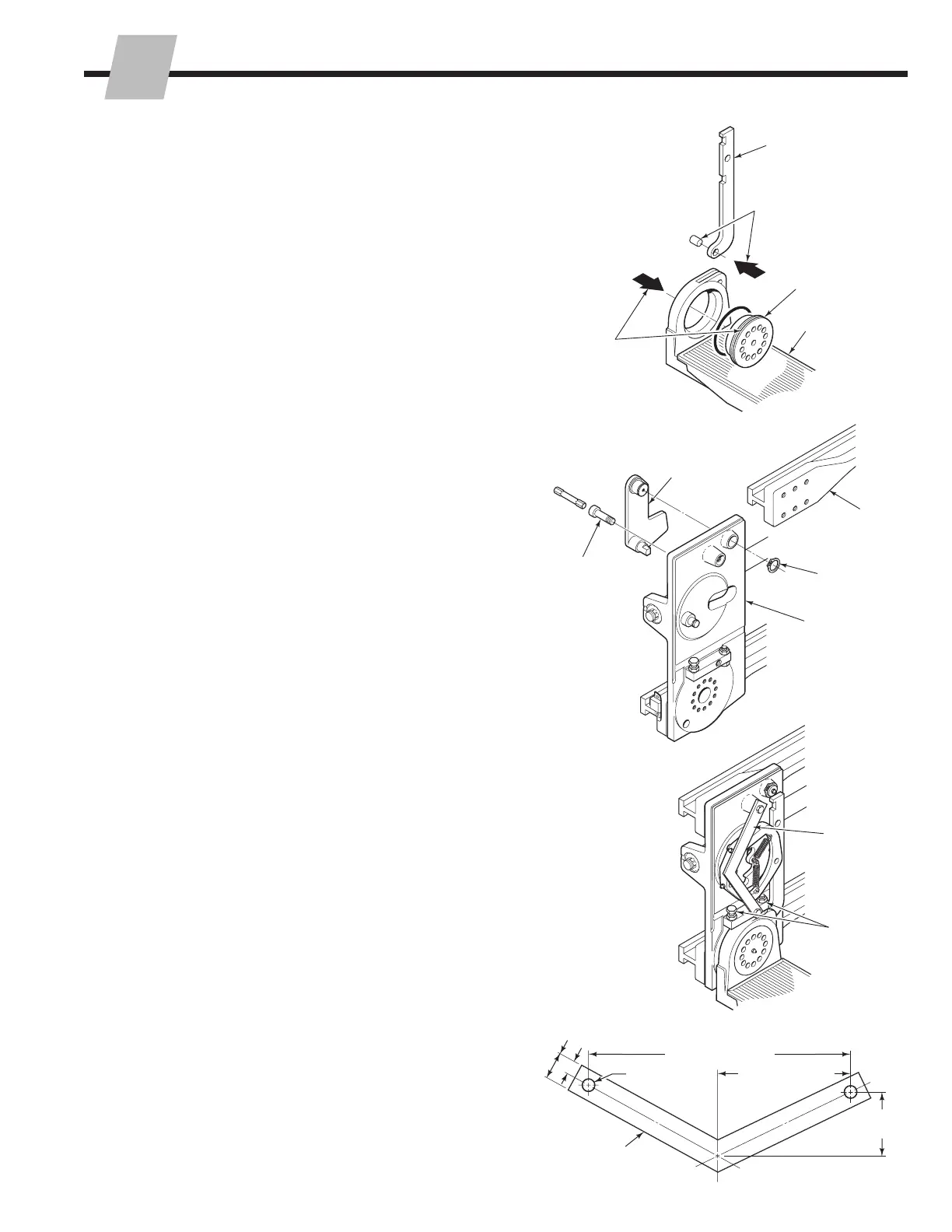

5.2-6 Turnafork Arm Service (Continued)

9 Remove the crank bar from the fork arm by driving out

the pivot pin from the front side of the fork arm.

10 Tap the bearing out of the fork arm from the back side

with a rubber mallet.

11 To remove the actuator, the upper arm bar must be

disassembled from the arm carrier. Remove the side

upper arm capscrews, as described in Section 5.2-2,

step 2. Slide the arm bar inward to gain access to the

actuator.

12 Remove the snap ring retaining the actuator to the arm

carrier, if equipped. Remove the actuator from the back

side of the arm carrier.

13 For reassembly, reverse the above procedures excepts

as follows:

• Inspect all components and bushings for wear.

Replace all worn components.

• Replace the fork arm bearing O-ring if damaged.

• Inspect the detent pin, spring, bushing and

wearplate. Replace all worn parts.

• Lubricate the fork arm bearing with chassis grease

prior to inserting into the fork arm.

• Use two of the bearing capscrews 180° apart as

guides to align the bearing/fork arm with the arm

carrier mounting holes during reassembly.

• Make sure the arm turns freely on the bearing after

tightening the capscrews.

• Lubricate all zerk fittings with chassis grease.

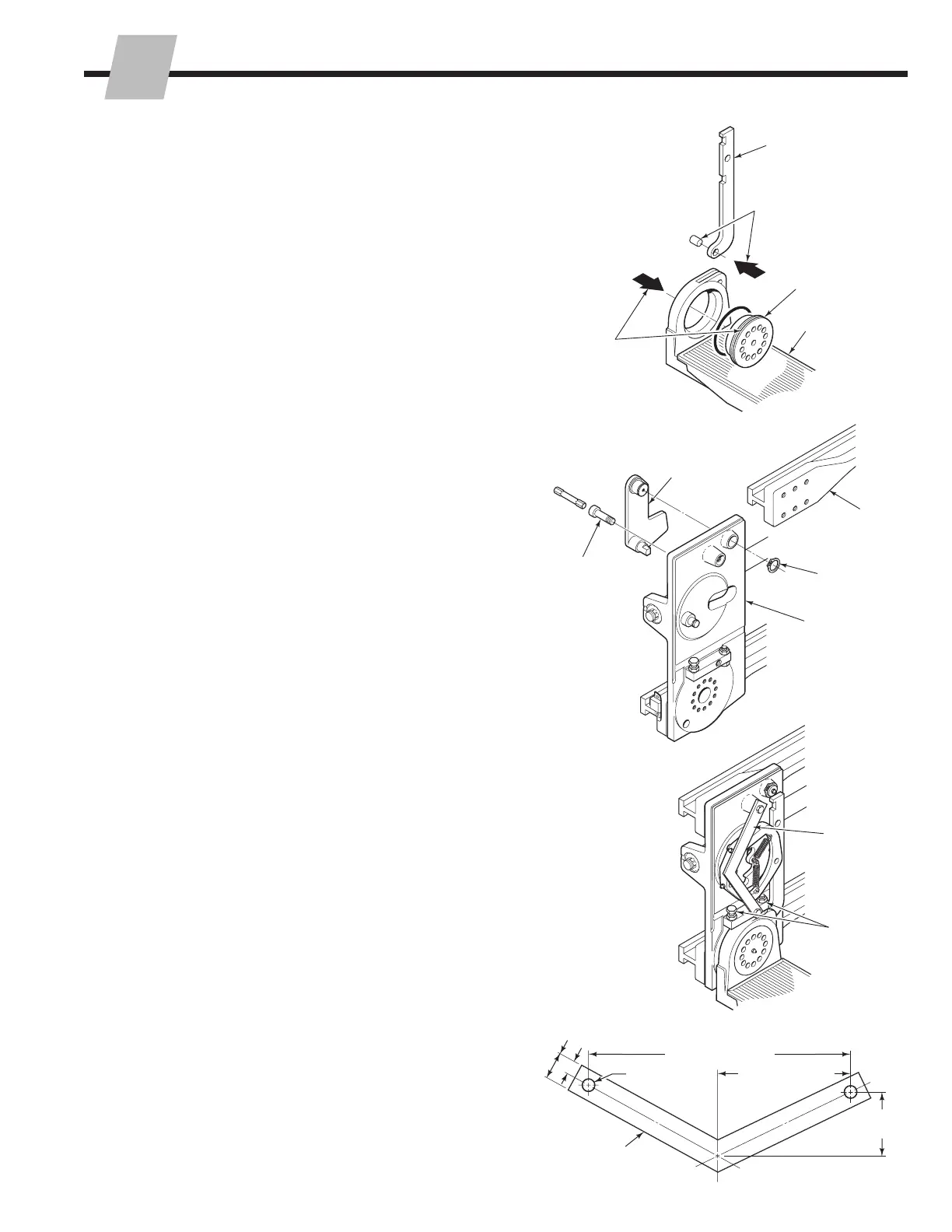

• On early style arms without a snap ring retaining

on bell crank, the fabricated bar shown below must

be installed. This bar allows the arms to be indexed

with the covers off to adjust the horizontal and

vertical stops.

• The two capscrew stops should be adjusted so the

arm stops at a true horizontal and vertical position

when it is indexed. In the vertical (clamp) position,

the capscrew should stop the arm so it just engages

the detent pin in the arm base. Tighten the nuts to

80–90 ft.-lbs. (110–122 Nm).

CL4407.eps

9

10

Crank Bar

Fork Arm Bearing

Fork Arm

CL4408.eps

Actuator

Upper

Arm Bar

Arm Carrier

12

11

CL4409.eps

Make a bar

to secure the

uncovered

mechanism

Capscrew

Stops

5.2-7 Turnafork Arm Indexing

Fully closing the arms depresses the actuators. This

releases the locking mechanism and causes the arms to

rotate. If the arms get out of phase (one or both arms not

horizontal or vertical), correct the problem as follows:

IMPORTANT: If the arms ever get out of phase, there may

be nothing mechanically wrong with the attachment. This

condition usually occurs when the actuators are not fully

depressed.

To reposition an arm manually: With the arms fully closed

(actuators fully depressed), reposition one arm by hand.

To reposition an arm hydraulically: Close the arms

hydraulically (actuators fully depressed). Then open the

arm slowly until you hear one click. Immediately close the

arms together again to bring them back in phase.

CL0343.eps

3.75 in.

(9.5 cm)

1.50 in. (38 mm)

.75 in. (19 mm)

MATERIAL:

.25 in. (7 mm)

Steel Plate

14.25 in. (36.2 cm)

7.12 in. (18.1 cm)

.75 in. (19 mm)

DIA. - 2 places

Loading...

Loading...