669224-R5

ERVICE

S

37

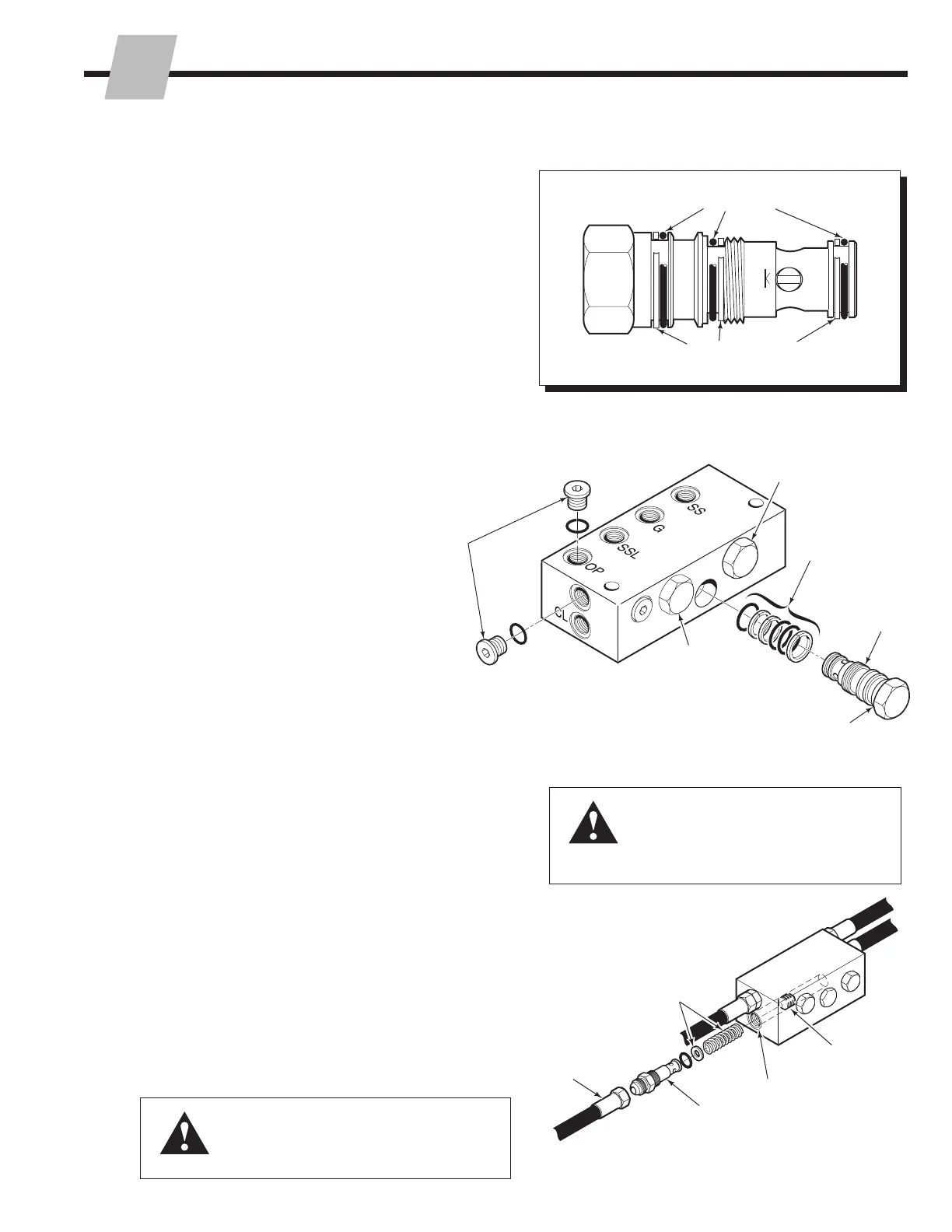

5.6-4 Check Valve Service –

Center Mount Valves

IMPORTANT: Service the check valve in a clean work

area.

1 Remove the cartridge valves. The non-sideshifting

check valve has one cartridge valve, the sideshift check

valve has three cartridge valves.

2 Remove all plugs and fittings.

3 Remove the O-rings and back-up rings from the

cartridge valve, fittings and plugs.

4 Clean all parts with cleaning solvent.

6 For reassembly, reverse the above procedures except

as follows:

• The cartridge valve back-up rings and O-rings must

be installed as shown to avoid seal damage during

reassembly.

• Lubricate cartridges and seals with petroleum jelly

prior to reassembly.

5.6-5 Eliminating the Arm Opening

Regenerative Function

The 25D, 35D, 40D and 50D attachments utilize a

regenerative hydraulic circuit in the arm opening mode.

The arms open at a faster speed than when closing. The

regenerative circuit can be eliminated (use Service Kit

212867) to give equal arm speed when opening and

closing the arms as follows:

1 Open the attachment arms to the width of the frame.

2 Remove the hose from the check valve port marked CL.

3 Remove the special fitting from the CL port.

NOTE: The spool must remain in the CL port.

4 Install the spring and spacer supplied with the kit into

the CL port, as shown.

5 Reinstall the special fitting and hose.

NOTE: Operate the attachment through several cycles to

remove trapped air in the system and to check for proper

operation. Check for leaks.

CL1012.eps

O-Ring

Back-Up Ring

CL4423.eps

2

3

1

Sideshift Right

Cartridge Valve

Clamp Cartridge

Valve

Sideshift Left

Cartridge Valve

WARNING: Before removing any hoses,

relieve pressure in the hydraulic system.

Turn the truck off, then open the truck

auxiliary control valve(s) several times in

both directions.

WARNING: Make sure that the special

fitting is always installed in the CL port.

The attachment's arms will not function

properly without the special fitting installed.

OP

CL

CL4424.eps

2

3

4

Special Fitting

Spacer, Spring

CL Port

Spool (Do Not

Remove)