669224-R5

ERVICE

S

25

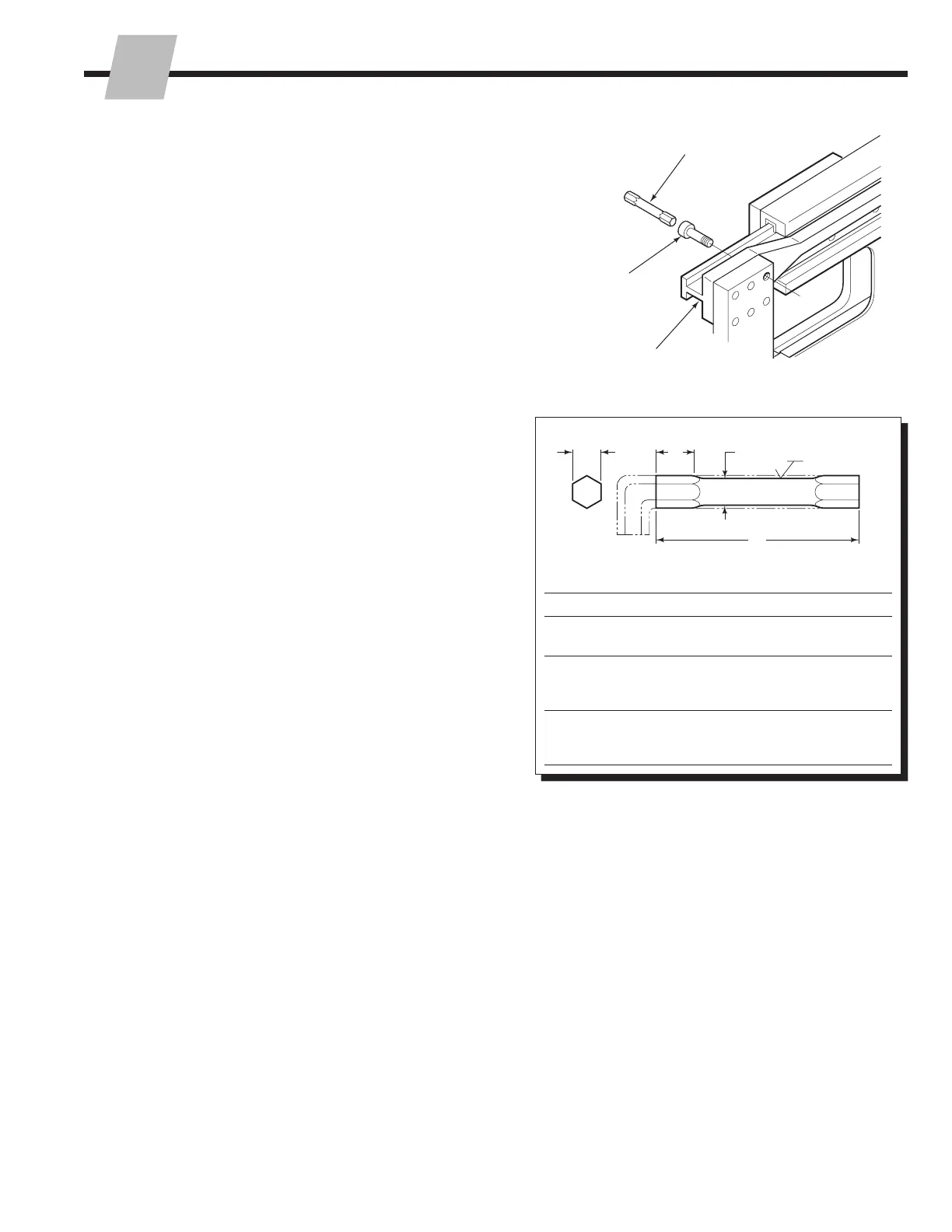

5.2-2 Bolt-On Arm Removal

The following procedures can be performed with the

attachment on the truck and with the arm assemblies on

the attachment. If the arm assemblies have been removed

(Section 5.2-1), lay the arm assembly down with the arm

back on the ground.

1 Extend the arms outside the width of the frame.

Remove the cotter pin, locking cap and nut retaining the

cylinder rod to the arm lug.

2 Remove the arm capscrews using drive extension

tool part no. 668020 (25D), 6676699 (35D, 40D, 50D)

or 676215 (70D, 80D, 100D). A torque multiplier is

required to remove and tighten the 70D, 80D, 100D

capscrews.

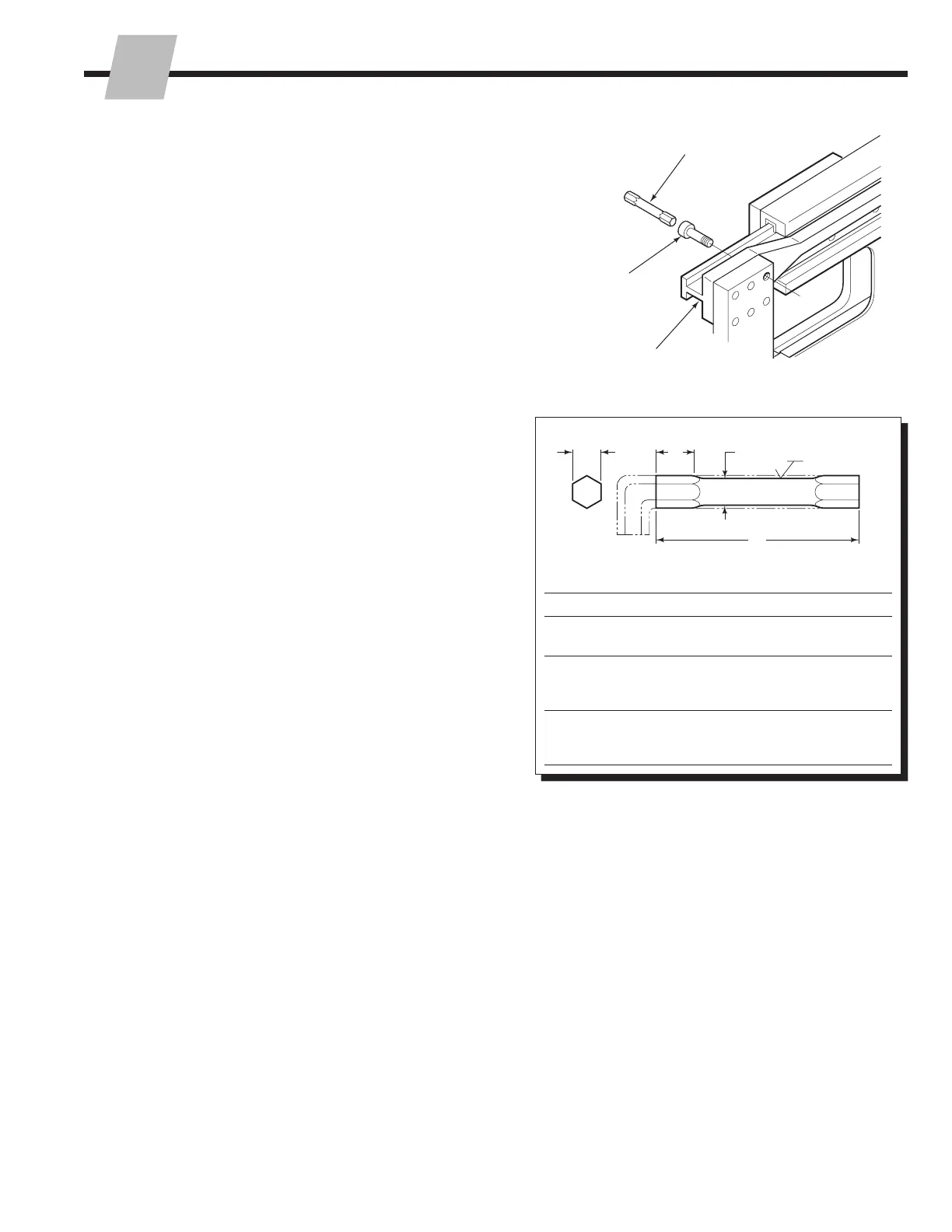

Short drive adapters are commercially available:

Williams .50 in. drive to .625 in. hex (25D) and .50

in. drive to .625 in. hex (35D, 40D, 50D) and .75 in.

drive to .75 in. hex (70D, 80D, 100D). Drive extension

dimensions are provided to make the tool from the allen

wrench. Do not use mild steel hex stock.

IMPORTANT: Be careful not to damage the arm bar.

Premature bearing failure will occur.

3 For reassembly, reverse the above procedures, except

for the following instructions:

• Tighten the capscrews (lubed) to the torque values

below. Arms should be free to slide in the frame

manually. If necessary, realign and retorque the

capscrews.

25D – 190–220 ft.-lbs. (257–298 Nm)

35D, 40D, 50D – 280–320 ft.-lbs. (380-434 Nm)

70D, 80D, 100D – 680–720 ft.-lbs. (922-976 Nm)

IMPORTANT: Be careful not to damage the arm bar.

Premature bearing failure will occur.

• Install the cylinder anchor nuts as described in

Section 5.2-1, Step 6.

IMPORTANT: Capscrews must be torqued to the values

shown above. If lost or broken, replace only with similar

GRADE 8 (ISO property class 10.9) hex socket head

capscrews.

CL0455.eps

Drive

Extension

2,3

Arm Bar

CL0456.eps

A

Hex

B

C

D

63

Dimensions – in. (mm)

Model A B C D

25D

.50

(12.7)

.75

(19.0)

.46

(11.6)

3.50

(88.0)

35D

40D

50D

.62

(15.7)

.50

(12.7)

.58

(14.7)

3.50

(88.0)

70D

80D

100D

.75

(19.0)

.50

(12.7)

.75

(19.0)

5.00

(127.0)

Loading...

Loading...