669224-R5

38

ERVICE

S

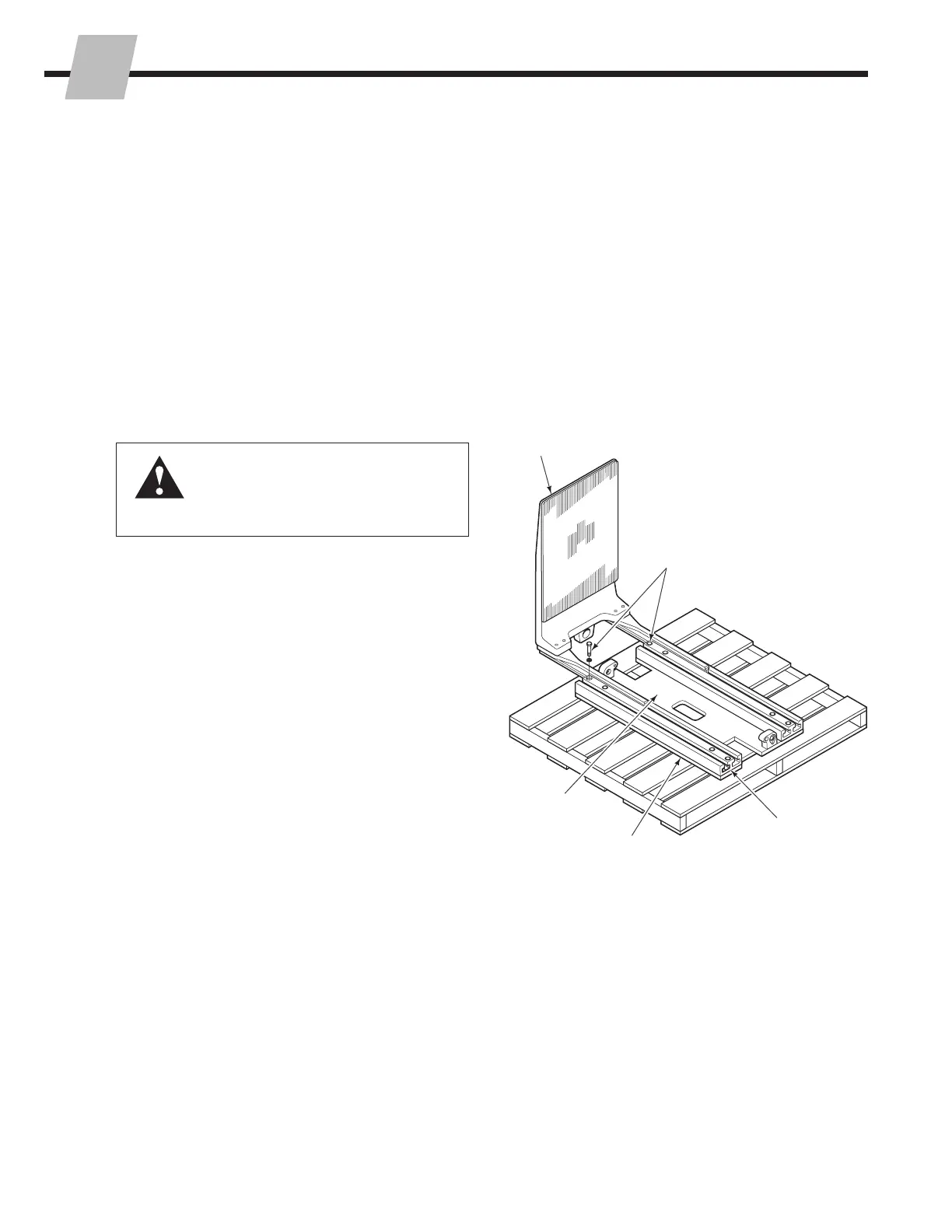

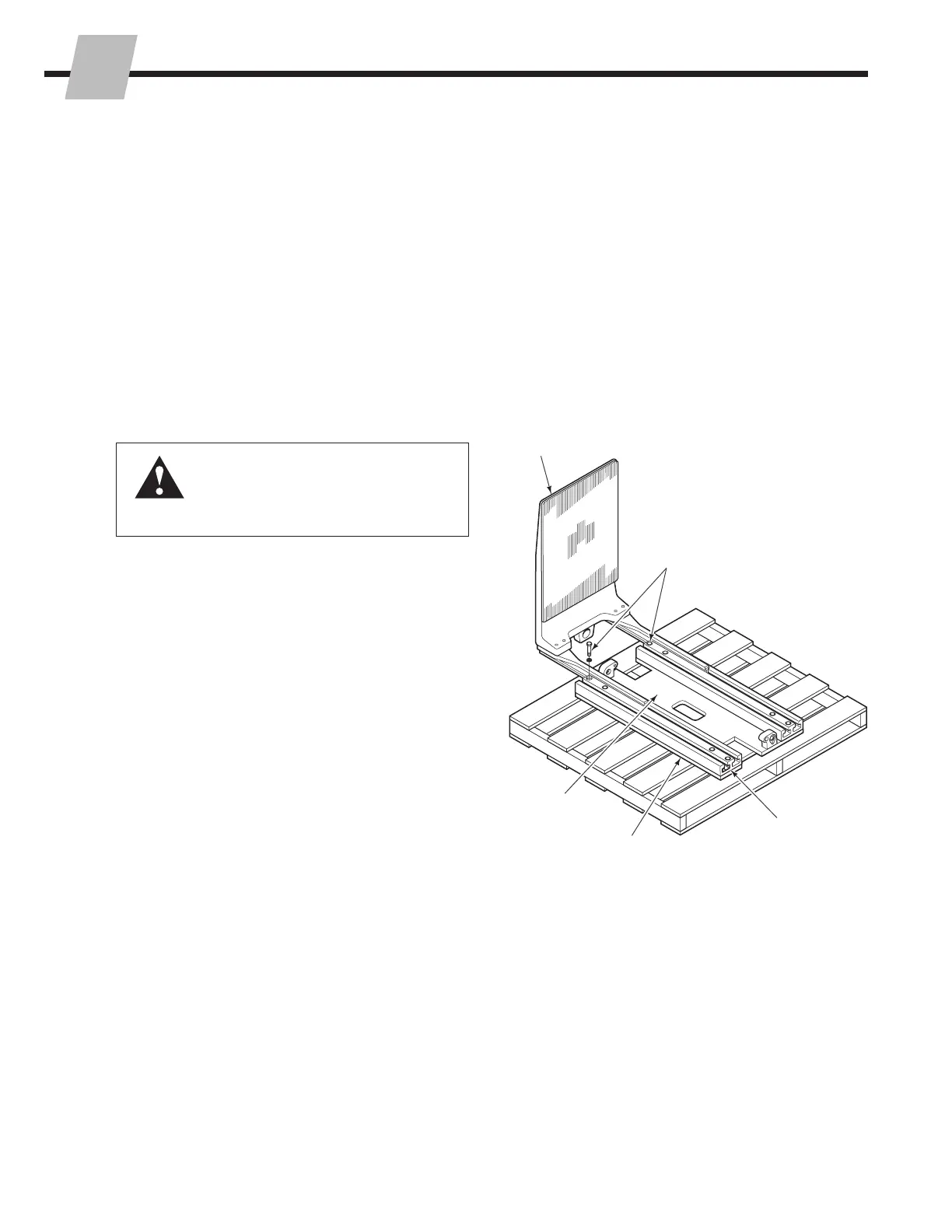

5.7 Base Unit

5.7-1 Frame and Mounting Plate

Disassembly and Reassembly

1 Remove the attachment from the truck as described in

Section 5.1

2 25D, 35D, 40D & 50D – Remove the check valve as

described in Section 5.6-1.

70D, 80D, 100D – Remove the check valve as

described in Section 5.6-2.

3 Remove the cylinders as described in Section 5.3-1.

4 Install two .50 in.–13 NC (M12) eyebolts in the frame.

Attach a suitable overhead chain hoist. Lay the clamp

over with the mounting brackets down.

WARNING: Check the attachment weight

(located on the nameplate) to make sure

the overhead hoist and chains or straps

are at least the rated capacity of the

attachment.

5 Pull the arm assemblies out of the frames.

6 Inspect arm bearings for wear. If the bearings are worn

in any area to a thickness less than .040 in. (1 mm), they

must be replaced. See Section 5.2-5 for removal and

installation.

7 Remove the capscrews fastening each frame to the

mounting plates. Tag the frame so they are reassembly

in their original position.

8 For reassembly, reverse the above procedures except

as follows:

• Fasten the frames to the mounting plates, leaving the

capscrews finger tight.

• Insert the arm assemblies into the frames.

• Position the frames and arms to allow unrestricted

arm assembly travel.

NOTE: Arm assemblies should be free to slide in the

frames manually. If necessary, realign and retighten

arm capscrews.

• Tighten the frame capscrew to a torque of:

25D, 35D – 55–65 ft.-lbs. (75–88 Nm)

40D, 50D – 105–115 ft.-lbs. (140–155 Nm)

70D, 80D, 100D – 180–200 ft.-lbs. (245–270 Nm)

CL4425.eps

5

8

6

Mounting

Plate

Frame

Loading...

Loading...