669224-R5

26

ERVICE

S

5.2-3 Multi-Purpose/Rigid and Drum Arm

Contact Surface Replacement

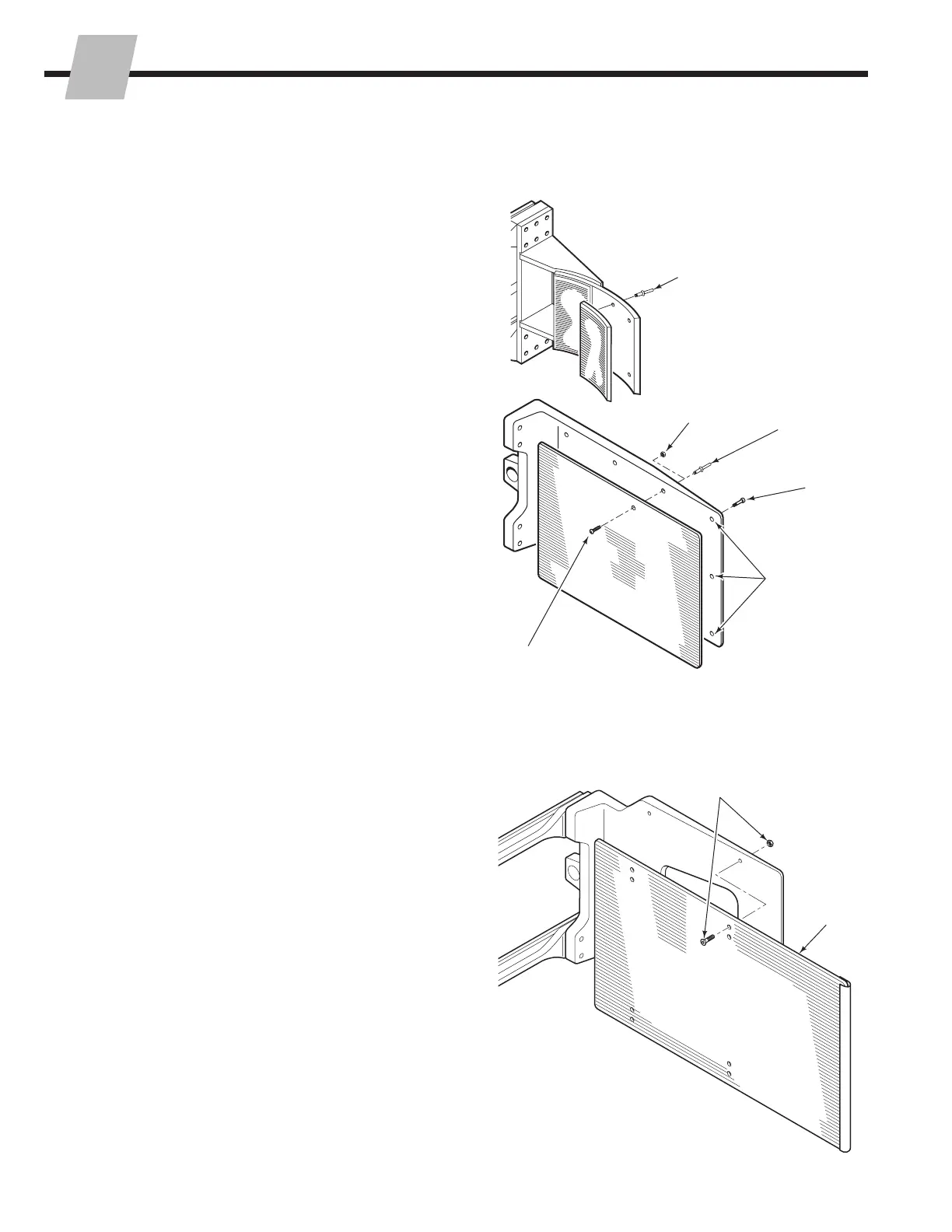

5.2-4 Rigid Arm Contact Pad

Rotation and Replacement

The following procedures can be performed with the

attachment mounted on the truck.

NOTE: The contact pads do not have a replaceable

surface. If a pad is completely worn, it must be replaced.

If only the lower section of the pads are worn, the pads can

be swapped side for side and reinstalled.

1 Remove the capscrews and nuts fastening the contact

pad to the stabilizer.

2 Remove the contact pad and swap side for side

or install new pads. Tighten the capscrews to

60–65 ft.-lbs. (80-88 Nm).

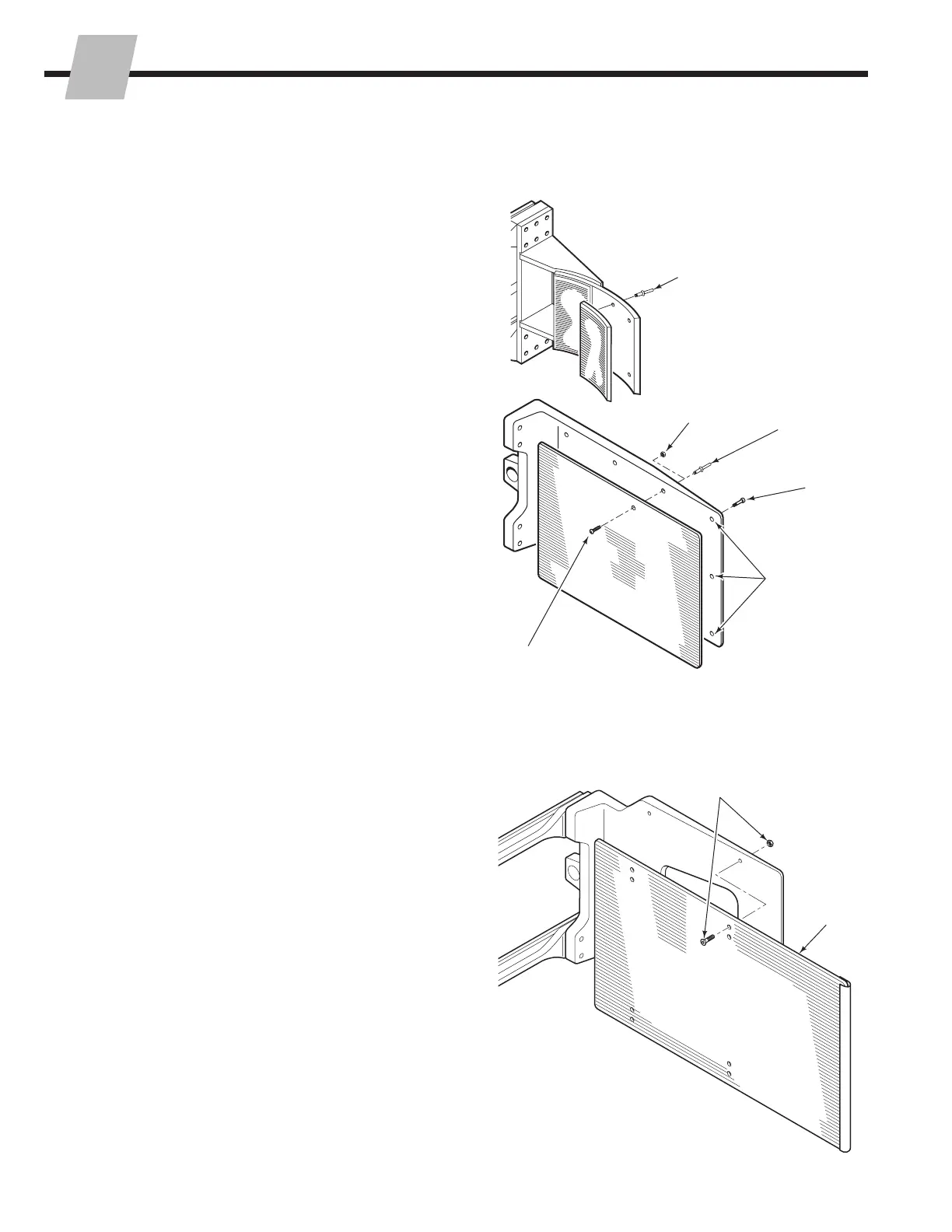

1 Drill out the rivets using .187 in. (4.8 mm) drill bit. Drill

from the front side of the arm.

2 Multi-Purpose/Rigid Arm Contact Pad Service Kits

include rivets and optional capscrews to be used

instead of rivets, if required. Drum Arm Service Kits

include rivets only.

Rivet Installation – Align the new contact surface to

the arm. Drill through using .187 in. (4.8 mm) drill bit.

Rivet the contact surface to the arm.

Optional Capscrew Installation – Align the new

contact surface to the arm. Drill the holes along the

front edge of the arm, through the contact pad with

a No. 7 tap drill. Drill the rest of the contact pad

with a .25 in. (6 mm) drill bit. Install the self-tapping

capscrews in the front edge holes. Install the button

head capscrews through the contact pad. Install the

nuts and tighten. The capscrew heads should be well

below the contact pad surface.

1

Contact

Pad

CL1528.eps

Rivet

Nut

Front Edge

Holes

Self

Tapping

Capscrew

Button Head

Capscrew

Rivet

CL1474.eps

Loading...

Loading...