669224-R5

PECIFICATIONS

S

40

GA0403.eps

6.1 Specifications

6.1-1 Hydraulics

6.1-2 Auxiliary Valve Functions

Check for compliance with ITA (ISO) standards:

Truck Relief Setting

2000 psi (140 bar) Recommended

2300 psi (160 bar) Maximum

Truck Flow Volume

➀

Min.

➁

Recommended Max.

➂

25D

4 GPM

(15 L/min.)

5.5 GPM

(21 L/min.)

5.5 GPM

(21 L/min.)

35D

4 GPM

(15 L/min.)

7 GPM

(26 L/min.)

7 GPM

(26 L/min.)

40D, 50D

4 GPM

(15 L/min.)

10 GPM

(38 L/min.)

10 GPM

(38 L/min.)

70D, 80D, 100D

7 GPM

(26 L/min.)

12 GPM

(45 L/min.)

15 GPM

(57 L/min.)

➀ Cascade D-Series Clamps are compatible with SAE 10W petroleum

base hydraulic fluid meeting Mil. Spec. MIL-0-5606 or MIL-0-

2104B. Use of synthetic or aqueous base hydraulic fluid is not

recommended. If fire resistant hydraulic fluid is required, special

seals must be used. Contact Cascade.

➁ Flow less than recommended will result in unequal arm movement.

➂ Flow greater than maximum can result in excessive heating,

reduced system performance and short hydraulic system life.

Hoses and Fittings

Clamp Function – All hoses and fittings should be at least

No. 8, minimum internal diameter of 13/32 in. (10 mm).

Sideshift Function – All hoses and fittings should be at

least No. 6, minimum internal diameter of 9/32 in. (7 mm).

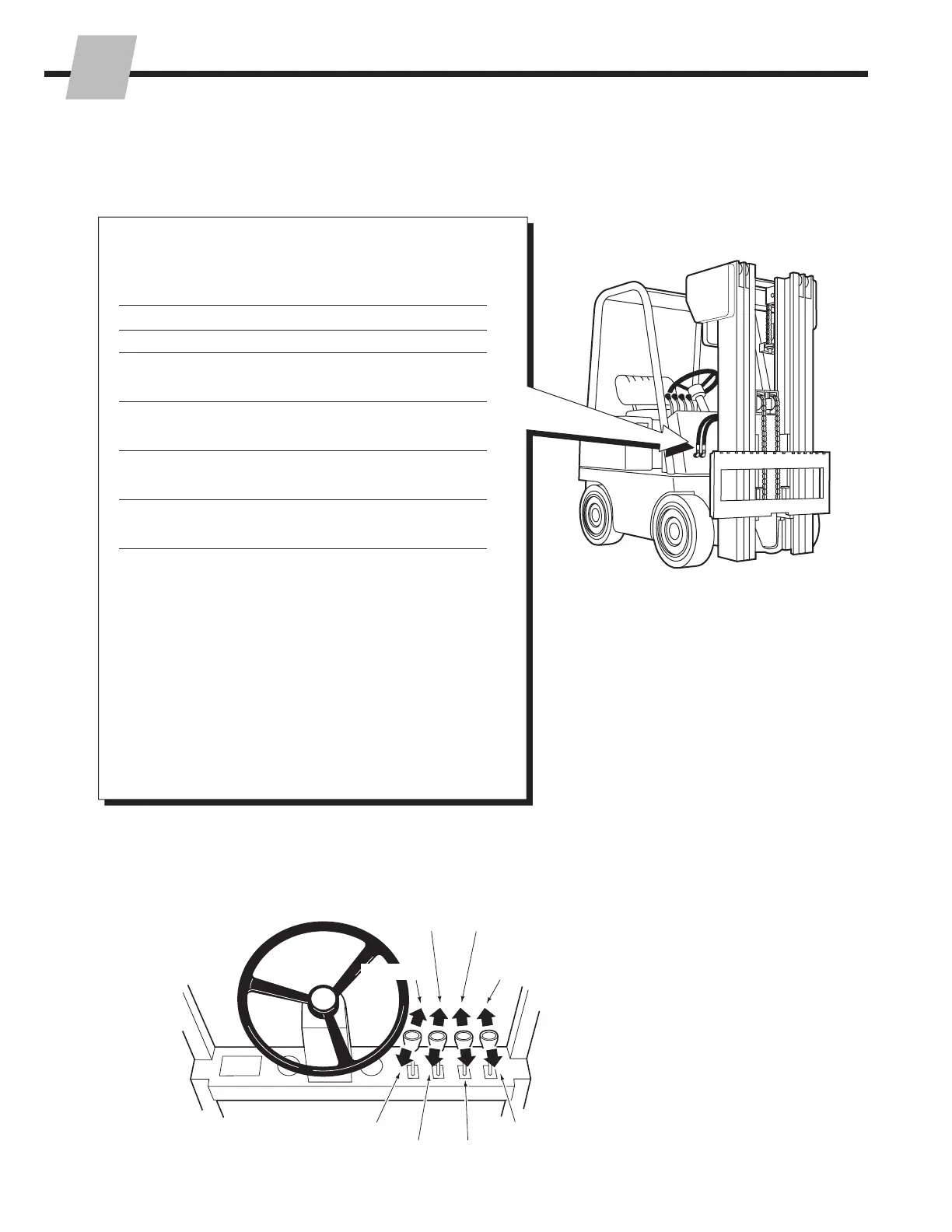

GA0082.eps

Hoist Down

Hoist Up

Tilt Forward

Tilt Backward

Sideshift Left

Sideshift Right

Open

Clamp

Loading...

Loading...