19

®

GENERAL

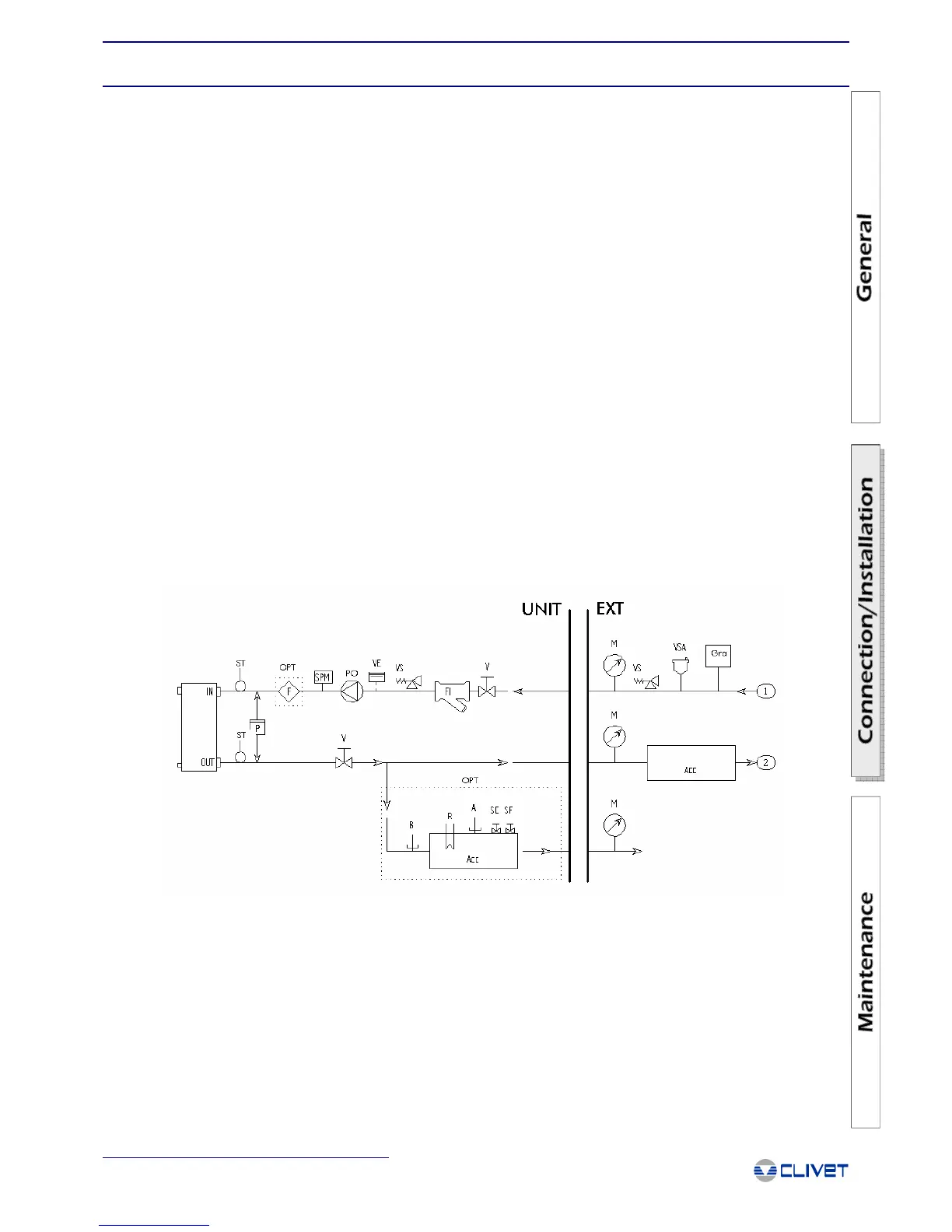

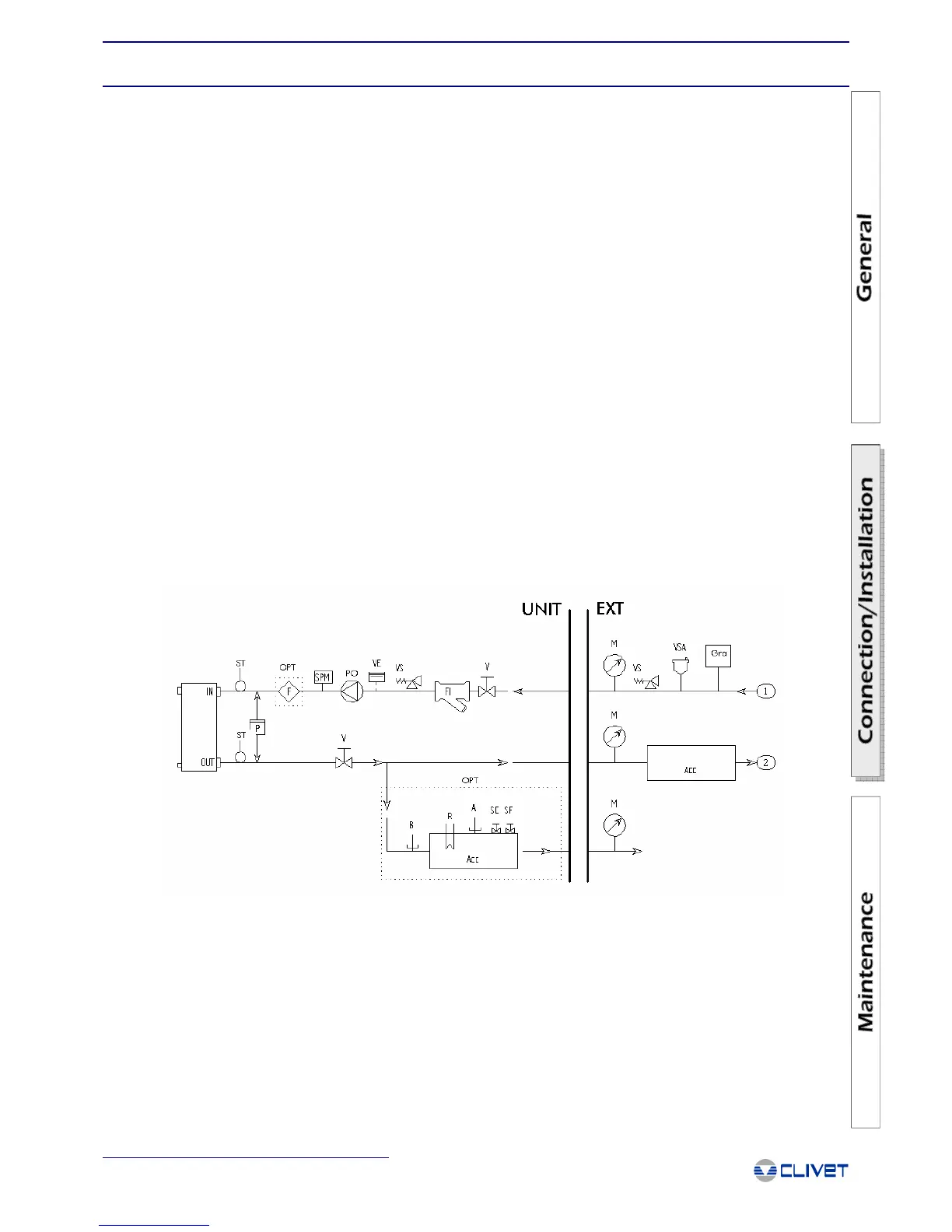

- WATER /AERAULIC CONNECTIONS -

Install ON/OFF valves next to the parts that are subject to maintenance. This allows their replacement without having to empty the

system.

The pipework must be designed with the minimum possible difference in height. Install automatic or manual vents in the high points of

the piping to allow the outlet of the air in the circuit. The system can be kept at the right pressure by means of an expansion vessel or

of a combined pressure reduction-discharge valve.

All the water pipes must be insulated in order to prevent condensation and heat dispersions along the piping itself. Make sure that the

insulation is vapour seal type.

Check for any leaks in the piping before insulating it. Air-venting and draining connections must protrude outside of the insulation so

as to be accessible.

The weight of the water connections must be adequately supported by the outside of the unit. The fittings on the exchanger must not

be subject to stress.

For units with antivibration mounts, flexible joints must be used for the water connections.

It is suggested to install thermometers, pressure gauges and bleed valves at the inlet/outlet of the unit, as this will help in the routine

checking and maintenance of the unit.

ATTENTION:

The installation of a steel mesh strainer on the inlet of the exchangers must be scheduled in order to protect them from foreign

materials.

Danger of frost.

If the unit and its water connections are subject to temperatures lower than 0°C, specific actions must be taken to avoid frost on the

exchanger and in the corresponding water circuit.

If the unit is fitted with an antifreeze heater (standard oR optional, depending on the model) on the exchanger side, this must always

be powered together with the heaters in the water circuit.

An antifreeze solution can be used (e.g. Ethylene Glycol) in the required percentage (see the Technical bulletin).

The water circuit (including the exchanger) can be drained during for seasonal shut-down.

Carefully check that there are no leaks from the pipes when filling the system.

Water/Aeraulic Connections

If the flow switch is not installed on the unit, it must be fitted in the system.

For units operating in parallel with on-board hydronic assemblies, a non-return valve should be fitted, to prevent the circulation of

water.

UNIT = unit

EXT = exterior

VS = water side safety valve

SPM = water side minimum pressure switch

SF = air vent stop valve

SC = discharge stop valve

P = differential pressure switch

B = water side low temperature switch

VE = expansion tank

V = cock

VSA = automatic air vent

ST = water inlet and outlet probes

F = optional flow switch

PO = pump

A = water side high temperature switch

R = resistor

FI = water side filter

M = manometer

ACC = storage

GRA = filling valve

OPT = optional

SUGGESTED WATER CONNECTION DIAGRAM

Loading...

Loading...