3-77 Ramp 4 S-ramp Ratio at Decel. Start

Range: Function:

50 %* [ 1 - 99 %] Enter the proportion of the total

ramp-down time

(parameter 3-72 Ramp 4 Ramp Down

Time) where the deceleration

torque increases. The larger the

percentage value, the greater the

jerk compensation achieved, and

thus the lower the torque jerks in

the application.

3-78 Ramp 4 S-ramp Ratio at Decel. End

Range: Function:

50 %* [ 1 - 99 %] Enter the proportion of the total

ramp-down time

(parameter 3-72 Ramp 4 Ramp Down

Time) where the deceleration

torque decreases. The larger the

percentage value, the greater the

jerk compensation achieved, and

thus the lower the torque jerks in

the application.

4.4.7 3-8* Other Ramps

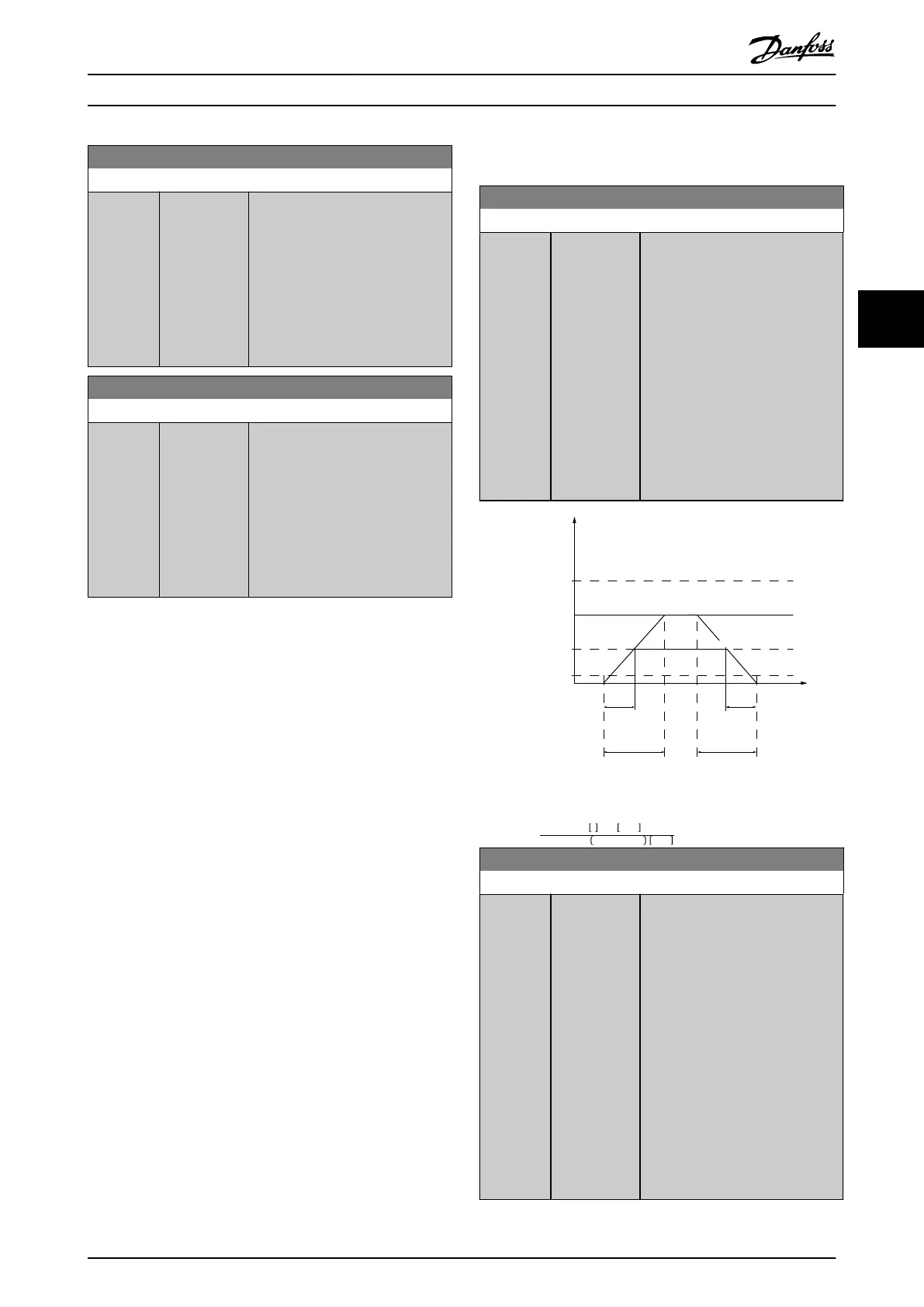

3-80 Jog Ramp Time

Range: Function:

Size

related*

[0.01 - 3600

s]

Enter the jog ramp time, that is the

acceleration/deceleration time

between 0 RPM and the rated

motor frequency n

s

. Ensure that the

resulting output current required

for the given jog ramp time does

not exceed the current limit in

parameter 4-18 Current Limit. The

jog ramp time starts after activation

of a jog signal via the LCP, a

selected digital input, or the serial

communication port. When jog

state is disabled, then the normal

ramping times are valid.

130BA070.10

Time

P 3-80

RPM

P 4-13 RPM

high limit

P 1-25

Motor speed

Jog speed

P 3-19

P 3-80

Ramp up

(acc)

Ramp down

(dec)

t jog t jog

P 4-11 RPM

low limit

Illustration 4.20 Jog Ramp Time

Par . 3 − 80 =

t

jog

s xn

s

RPM

Δ jogspeed par . 3 − 19 RPM

3-81 Quick Stop Ramp Time

Range: Function:

Size

related*

[0.01 - 3600

s]

Enter the quick–stop ramp-down

time, that is the deceleration time

from the synchronous motor speed

to 0 RPM. Ensure that no resulting

overvoltage occurs in the inverter

due to regenerative operation of

the motor required to achieve the

given ramp-down time. Ensure also

that the generated current required

to achieve the given ramp-down

time does not exceed the current

limit (set in parameter 4-18 Current

Limit). Quick stop is activated with

a signal on a selected digital input,

or via the serial communication

port.

Parameter Descriptions Programming Guide

MG06J202 Danfoss A/S © 03/2019 All rights reserved. 59

4 4

Loading...

Loading...