Page 5-2

Effective 10/02For more information visit: www.cutler-hammer.eaton.comIL17562BH04

CAUTION

MANY OF THE PROTECTION FUNCTIONS OF THE MP-3000

INCLUDING THE MOTOR THERMAL PROTECTION ALGORITHM,

USE THE FLA SETTING VALUE TO CALCULATE TRIP POINTS. IF

THE USER ENTERS AN INCORRECT SETTING, MANY PROTEC-

TION FUNCTIONS MAY NOT OPERATE AS DESIGNED AND THE

MOTOR MAY BE DAMAGED.

5.1.2 Setting P1L2, Locked-Rotor Current (LRC)

Set to the locked-rotor current (the current the motor draws when

stalled), in percent of FLA (see P1L1). Use motor nameplate or

manufacturer’s data.

5.1.3 Setting P1L3, Maximum Allowable Stall or Locked-Rotor

Time (LRT)

Specifies how long a locked-rotor or stall condition can be maintained

before the motor is damaged, in seconds, for a cold start. Use motor

nameplate or manufacturer’s data.

LRC and LRT combine to specify a point on the motor damage curve

(Figure 9.4) which, when reached during a start, causes a locked-rotor

trip. Refer to subsection 9.1.3 for a detailed explanation.

CAUTION

INCORRECT SETTING VALUES FOR THESE FUNCTIONS CAN RESULT

IN EXCESSIVE ROTOR TEMPERATURES AND MOTOR DAMAGE.

5.1.4 Setting P1L4, Ultimate Trip Current (UTC)

Sets the current level above which a trip will eventually occur when no

RTD stator temperature data is available, in percent of FLA. This value

represents the limit line on the running (upper) portion of the non-RTD

motor damage curve of Figure 9.4.

NOTE: This UTC setting is where the user considers the service factor

rating of the motor. Never adjust the FLA setting P1L1

according to the service factor (see subsection 9.1.3.3).

For normal use, set UTC to service factor times 100%. The available

range is 85% to 150%. The service factor is found on the motor

nameplate or in manufacturer’s data.

Note that the relay will not trip at the moment the current goes above

UTC during motor running. Instead, it models the gradual stator

heating for currents above UTC, and will trip only after some time has

passed. The trip time depends on a variety of setting and operating

factors, including motor nameplate data contained in other setting values.

Use a conservative, or lower, value of UTC than that dictated by the

service factor if motor ambient temperatures may rise above 40ºC and

the optional URTD Module is not used (see Subsection 9.1.1). Also,

consider lowering the UTC if the motor is suitably rated, yet additional

safety is critical for the application.

CAUTION

IF UTC IS SET ABOVE 100 PERCENT TIMES THE SERVICE

FACTOR, MOTOR DAMAGE COULD RESULT.

5.1.5 Setting P1L5, Phase Current Transformer Ratio (PCT)

Specifies the numerator of the turns ratio of the main phase current

transformers. Obtain from the Ct nameplate or from the installation drawings,

watching for the use of ratio taps on Cts which have tapped windings.

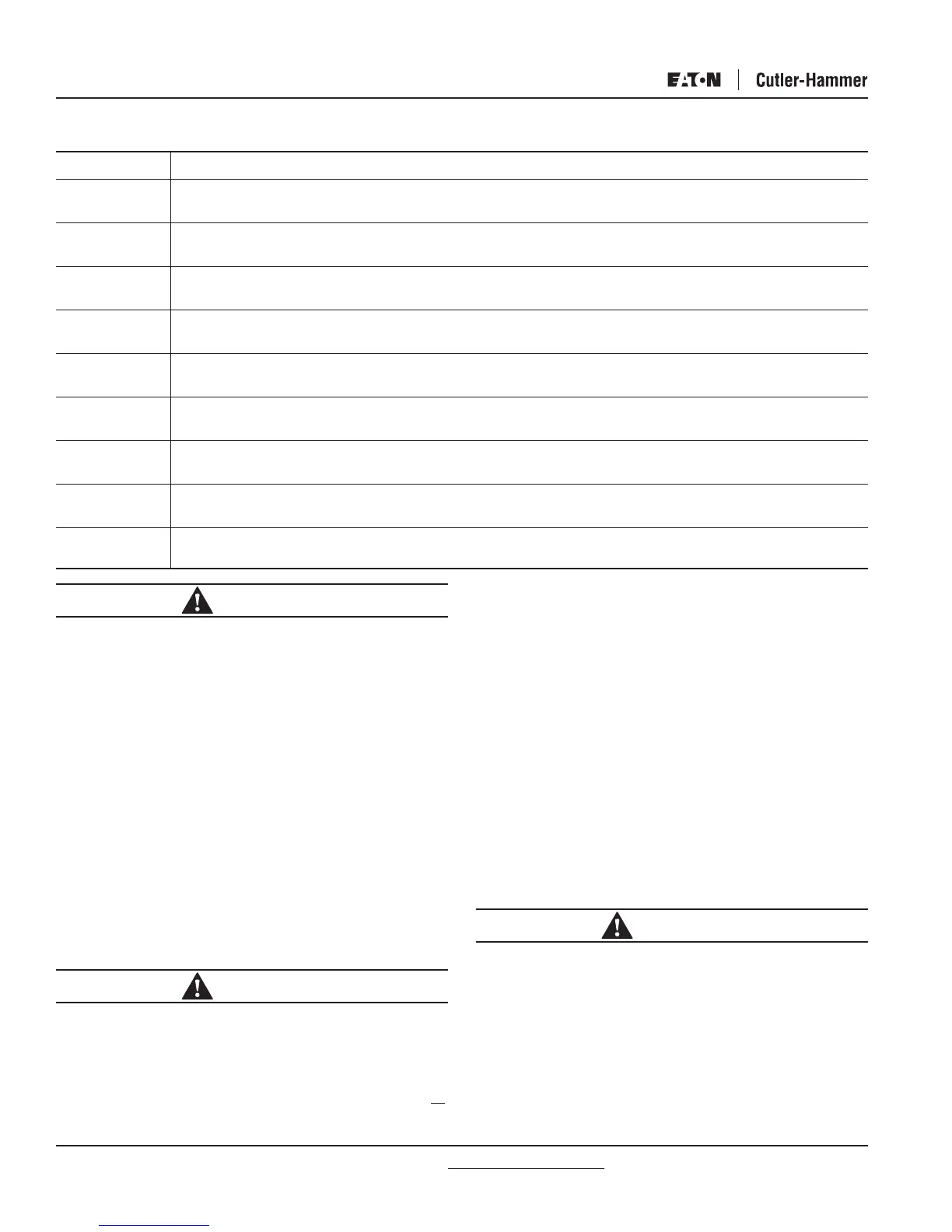

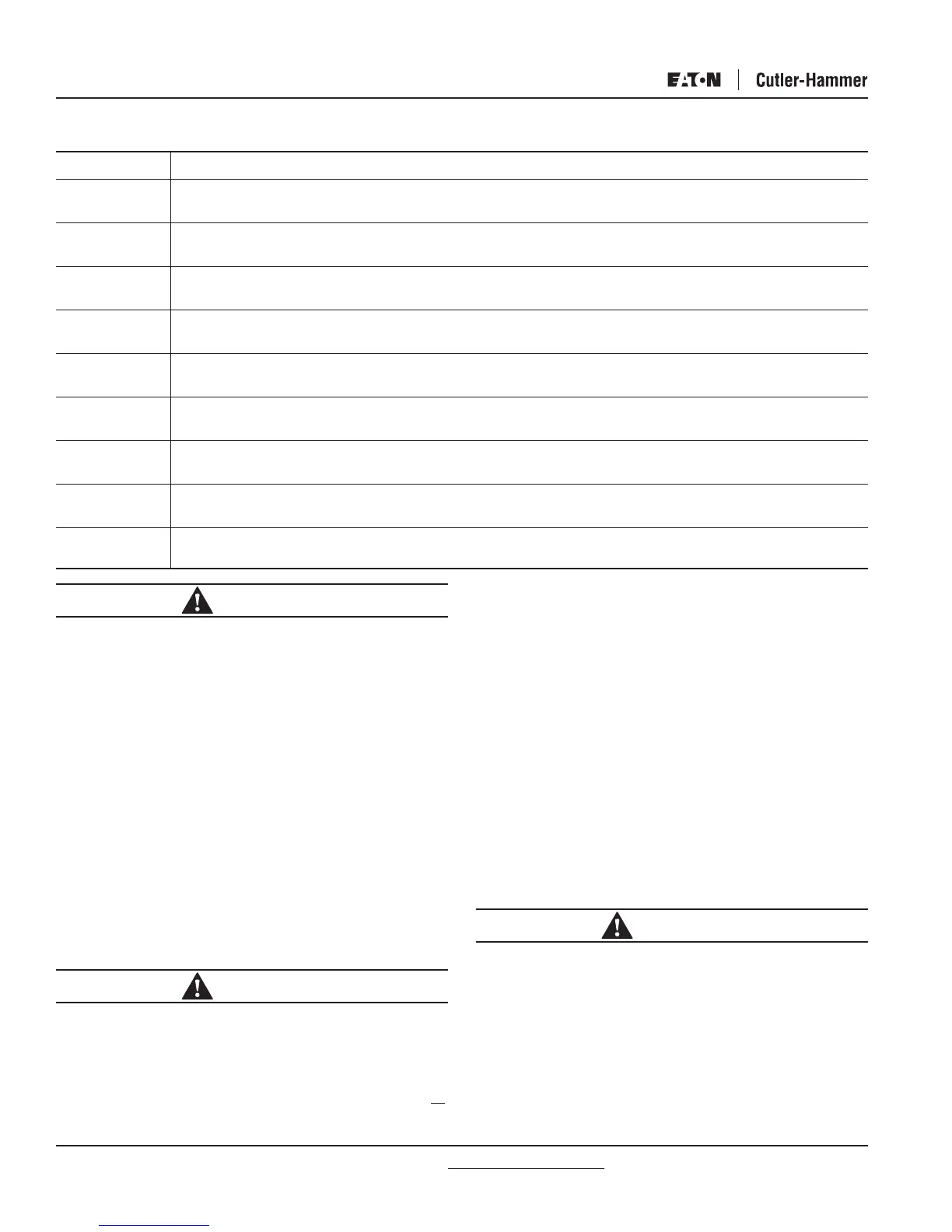

Display Complete Help Message

FLA CT L THE RATIO OF FLA TO CT RATIO IS BELOW .25—INCREASE FLA OR DECREASE CT RATIO—PRESS

PROGRAM TO CONTINUE

FLA CT H THE RATIO OF FLA TO CT RATIO IS ABOVE 1.5—DECREASE FLA OR INCREASE CT RATIO—PRESS

PROGRAM TO CONTINUE

IOC OUT IOC SETTING IS OUT OF RANGE—DECREASE IOC OR DECREASE FLA OR INCREASE CT RATIO—PRESS

PROGRAM TO CONTINUE’

JAMT OUT JAM TRIP SETTING IS OUT OF RANGE—DECREASE JAM TRIP OR DECREASE FLA OR INCREASE CT

RATIO—PRESS PROGRAM TO CONTINUE

JAMA OUT JAM ALARM SETTING IS OUT OF RANGE—DECREASE JAM ALARM OR DECREASE FLA OR INCREASE

CT RATIO—PRESS PROGRAM TO CONTINUE

ULT LOW UNDERLOAD TRIP SETTING IS LESS THAN STOP CURRENT LEVEL — DECREASE STOP CURRENT

LEVEL OR INCREASE UNDERLOAD TRIP LEVEL — PRESS PROGRAM TO CONTINUE

ULA LOW UNDERLOAD ALARM SETTING IS LESS THAN STOP CURRENT LEVEL — DECREASE STOP CURRENT

LEVEL OR INCREASE UNDERLOAD ALARM LEVEL — PRESS PROGRAM TO CONTINUE

STP HIGH STOP CURRENT LEVEL IS ABOVE THE START LEVEL — DECREASE STOP CURRENT LEVEL — PRESS

PROGRAM TO CONTINUE

TRNS LOW STOP CURRENT LEVEL IS ABOVE THE TRANSITION LEVEL — DECREASE STOP CURRENT LEVEL OR

INCREASE TRANSITION LEVEL — PRESS PROGRAM TO CONTINUE

Table 5.1 Inconsistent Settings Messages

Loading...

Loading...