For more information visit: www.cutler-hammer.eaton.com

Page 9-3

Effective 10/02 IL17562BH04

• Locked-rotor amperes of 6.1 times FLA

• Maximum allowable stall or locked-rotor time of 15 seconds, cold

start

• Ultimate trip level of 100 percent of FLA (service factor = 1.0)

• Motor running; normally loaded at 90 percent of FLA

• Underload protection at 60 percent of FLA with a 5-second run delay

• Jam protection at 180 percent of FLA with a 5-second run delay

The MP-3000 recognition of the transition from start to run has no

impact on this protection curve, but defines when the displays and

indications change from START to RUN. For a reduced-voltage starter,

the transition function also defines when the AUX2 output relay

switches the starter from reduced to normal running voltage. See 9.2.1

below. The user might elect to transition on time (e.g. set P5L7 to TRN

TIME and P5L6, TRNT=10 seconds) or current (e.g. set P5L7 to TRN I

and P5L5, TRNC to 130 % of FLA), among other options.

Figure 9.5 shows the impact of a stator RTD measurement. Look at the

time period after 60 seconds (near the top). When RTDs report low

stator temperature, the motor can run continuously with current well

above (to the right of) the UTC line. The lower the stator temperature,

the higher the acceptable sustained current moves beyond UTC -

200% of FLA in the example. A hotter stator, perhaps caused by a high

ambient temperature or a cooling blockage, shifts the curve to the left

and lowers the acceptable level of I

2

t. Be sure to set a suitable RTD

temperature trip value (WD T) according to 9.1.8 below; a setting of

OFF causes the relay to revert to the non-RTD algorithm even if RTDs

are connected.

9.1.5 Load Shedding Function

In some applications, the MP-3000 can forestall a jam alarm or trip, or

a thermal trip, by sending a signal to the process to reduce loading.

The load-shedding function, if enabled, will close or open the AUX1

contact to shed process load when the motor load current goes above

the load-shed threshold LSPU, P9L1, for a time exceeding the load-

shed run delay LSDL, P9L3. This could, for example, be connected to

stop flow of material into the driven process until the load current drops

below the load-shed dropout threshold LSDO, P9L2 for time LSDL,

P9L3.

Set the load-shed pickup current LSPU, P9L1 comfortably below the jam

trip level. It may be useful to set it below UTC, P1L4, particularly if RTDs

are not used. See Section 5 explanation for settings P9L1 to P9L3, and

for imposed relationship rules on load shedding pickup, dropout, and time

delay settings.

9.1.6 Long Acceleration Time

The user can temporarily defeat the I

2

t thermal protection limit after a

start by setting a Long Acceleration Time delay (LAT, P5L10). This can

be a dangerous setting which blocks thermal tripping and holds the

bucket at a 100% level if the load takes a long time to reach running

speed. An example is a motor spinning a large centrifuge. In using

LAT, the user is taking advantage of the partial cooling from airflow

produced by motor spinning at below-normal speed, as compared to

unfanned heating of a locked rotor. The motor must be rated for this

severe starting duty. Also, the user must insure that the motor actually

has begun to spin well before the locked-rotor time has expired. This

is accomplished by connecting a zero-speed switch to Discrete Input 1

and setting P5L11 ZSW = ON. The zero-speed switch is a contact that

is closed when the motor is at rest, and opens as the motor begins to

spin, usually at 5-10% of running speed. If ZSW is set to ON and the

MP-3000 does not see the contact open in ½ the locked-rotor time

setting, it trips the motor.

WARNING

TURN OFF LAT UNLESS THE APPLICATION SPECIFICALLY

DEMANDS IT. USE A ZERO-SPEED SWITCH WITH LAT. USING AN

LAT SETTING GREATER THAN LOCKED-ROTOR TIME WITHOUT A

ZERO-SPEED SWITCH WILL TEMPORARILY DEFEAT THERMAL

PROTECTION, AND RUIN THE MOTOR IF THE ROTOR ACTUALLY

IS LOCKED.

If LAT is used, check the settings of transition time TRNT, P5L6 and jam

start delay JMSD, P3L7 to be sure they are coordinated with the

prolonged starting cycle.

9.1.7 Using The Starting Current Profile Function

If the MP-3000 is communicating with a Cutler-Hammer PowerNet host

computer, the user can upload the actual time history of the starting

current from the moment of a particular start to a time well past the set

locked-rotor time. The actual current-versus-time profile can be

visually checked against the cold-start protection curve, which

PowerNet plots for comparison. The PowerNet plot also includes the

long-acceleration extension of the thermal curve, and the jam trip limit.

The profiled starting current is the average rms phase current.

The MP-3000 stores the last four starting current profiles. This profile

data cannot be read on the front-panel display.

9.1.8 Thermal Protection by Direct Measurement

The effects of the motor winding temperature alarm and trip (P2L2 and

P2L3) settings, which can be used with RTDs, are not shown in

Figure 9.5. These direct temperature functions protect independently

of the I

2

t algorithm. For the thermal algorithm to take advantage of the

stator RTDs, the thermal direct tripping must be turned on by setting a

suitable temperature for trip, not OFF. The settings for these functions

should be based on the recommended maximum stator insulation

temperature, as indicated by the motor manufacturer’s insulation

classification on the nameplate.

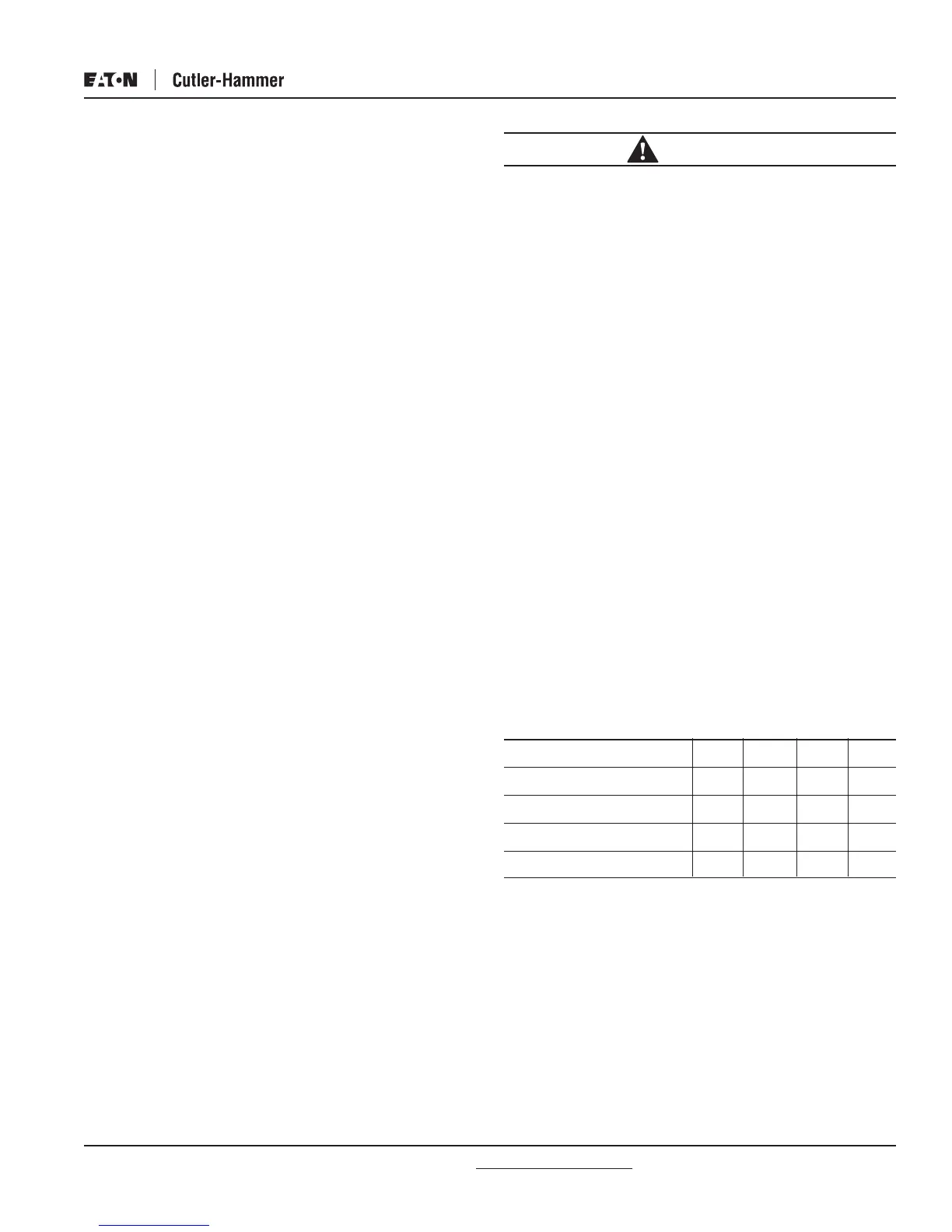

Table 9-1 Example Insulation Temperature Classes (from

NEMA MG-1)

NOTE: Rising winding temperature has to travel through the insulation

and stator iron to heat the RTD. When setting stator tempera-

ture alarm and direct thermal trip temperatures, keep in mind

that the actual hottest-spot insulation temperature may be 5 to

15 degrees C above the hottest RTD measurement. This

additional temperature rise above insulation rating may cause

the insulation to age twice as quickly as it would if kept within

rating. Set thermal trip temperature a little below insulation

rating for longest motor life.

Class A B F H

Ambient Temp., deg. C 40 40 40 40

Allowable Rise, deg. C 60 80 105 125

Hot Spot Allowance, deg. C 5 10 10 15

Hot Spot Temp., deg. C 105 130 155 180

Loading...

Loading...