12

Compressor Start Circuit

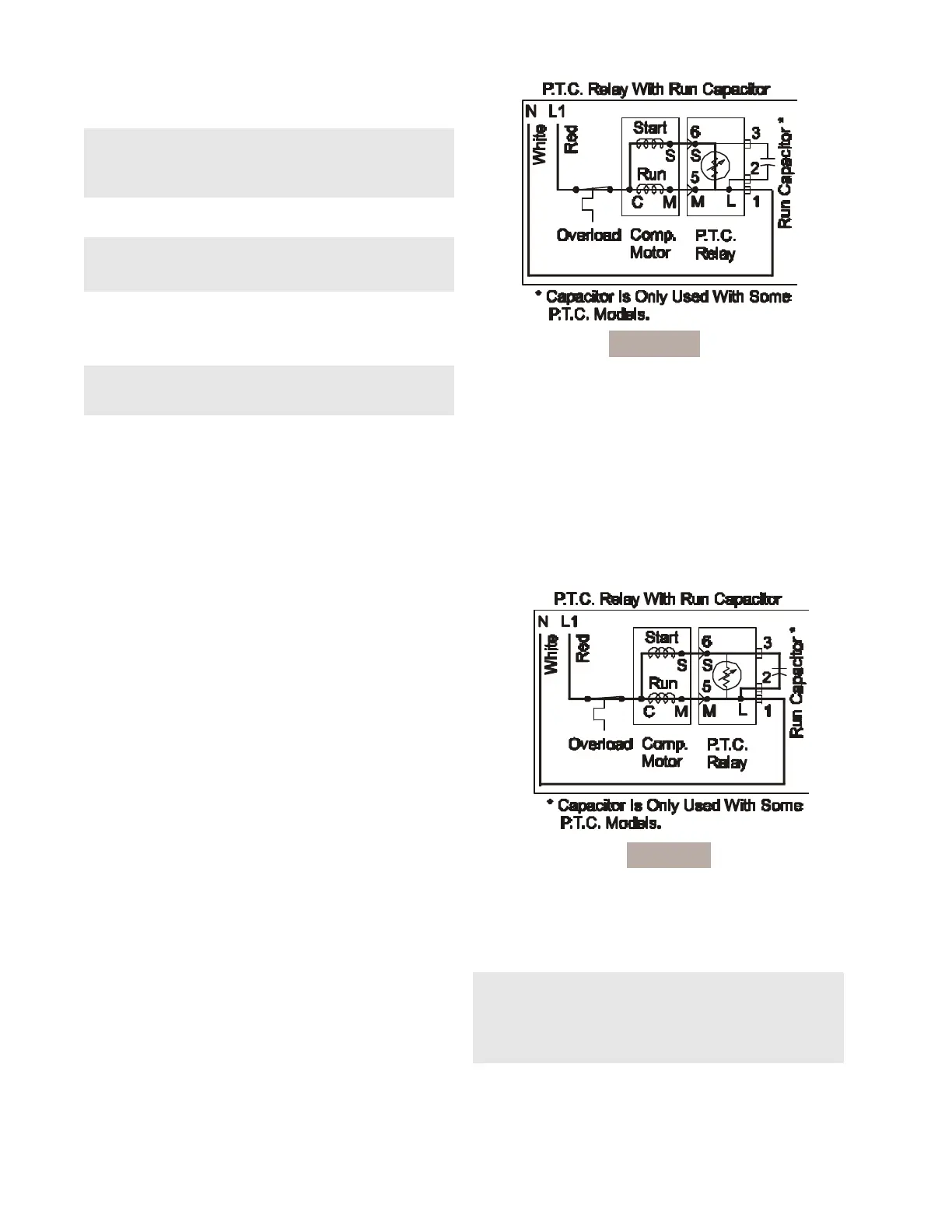

When the compressor circuit is first energized, the solid

state relay has low resistance (3-12 ohms), and both the

run and start windings are energized to start the

compressor. The run capacitor

1

is being bypassed by

the relay, and it has a minor function during compressor

starting (See Figure C3).

Compressor Run Circuit

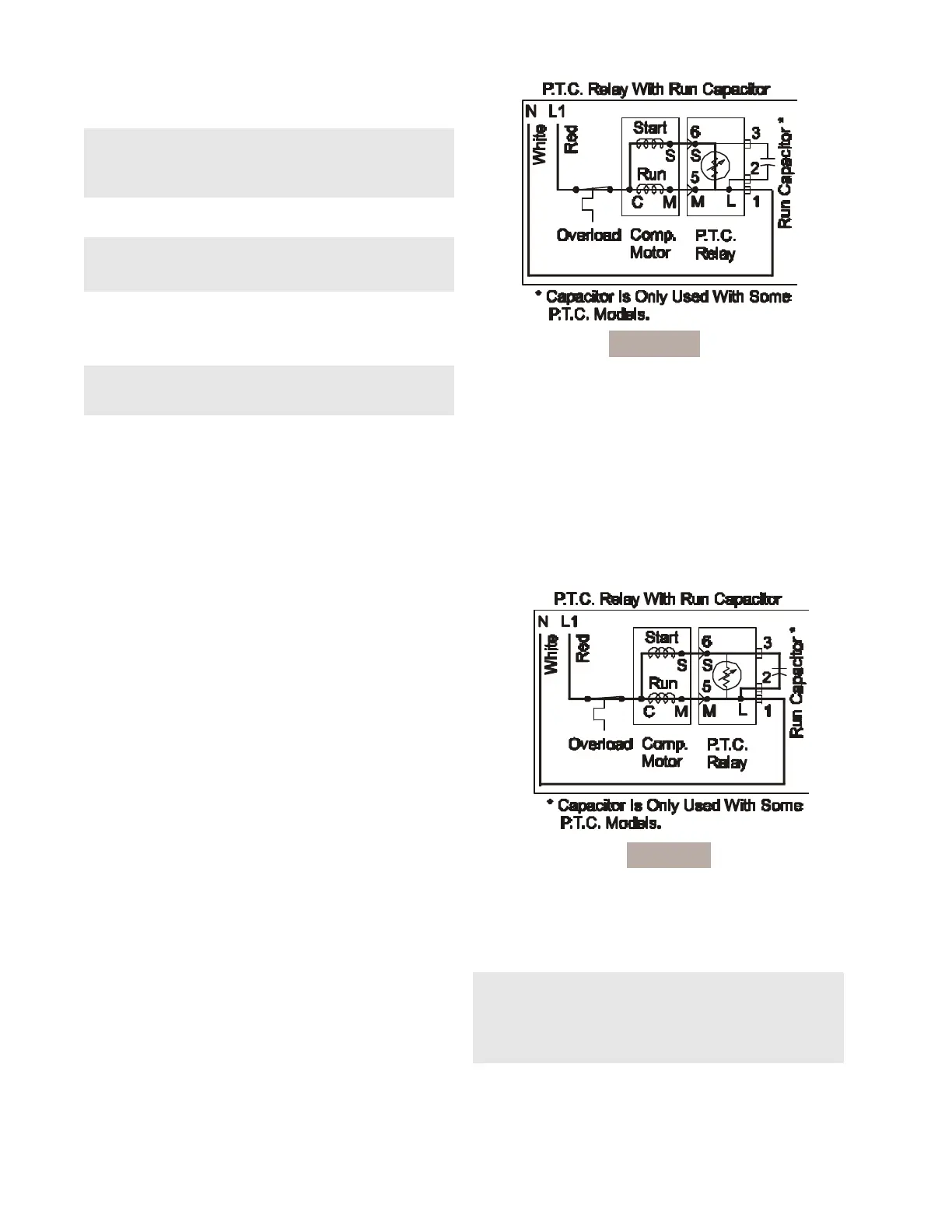

When the self-heating solid state relay has reached

sufficient temperature, it will abruptly change from low

resistance (3-12 ohms) to very high resistance (10-20K

ohms) and, in effect, switches off the start windings.

The relay no longer shunts the run capacitor. The run

capacitor is now in series with the start windings. The

only purpose of the run capacitor is to improve

compressor operating efficiency, which it does by cor-

recting the power factor of the compressor motor (See

Figure C4).

Figure C4

7. If ohm readings are out of range, install new

Starter/Overload Assembly.

NOTE: The Overload Protector is built into the

Starter Overload Assembly. It cannot be read

independently from the Starter.

8. Reverse this procedure to re-assemble.

NOTE: When replacing leads to the PTC Relay,

ensure the locking tabs snap back into the terminal.

Run Capacitor

The run capacitor has permanently attached terminals

which are connected to relay terminals 2 and 3.

To Check/Replace The Run Capacitor

1. Disconnect electrical supply to refrigerator.

2. Remove bale wire holding relay to compressor.

2. Use small, flat-bladed screwdriver to disconnect

leads to relay assembly.

3. Use flat-bladed screwdriver and gently pry

capacitor from relay assembly.

4. Discharge capacitor by shorting across terminals

with 500K (1 watt) resistor for one minute.

5. Use ohmmeter set on the “Ohms times 1000”

scale (if available), to check resistance across

capacitor wire terminals.

• The needle should jump towards zero ohms

and quickly move back to infinity.

• If the needle does not move, the capacitor is

open.

• If the needle reads a constant value at or near

zero ohms, the capacitor is shorted out.

• If the needle jumps toward zero and then

moves back to constant high resistance (not

infinity), the capacitor has a high resistance

leak.

6. If ohm readings are out of range, replace capacitor.

7. Reverse procedures to re-assemble.

Figure C3

NOTE: Some models are not equipped with a Run

capacitor

COMPRESSOR OPERATING CHARACTERISTICS

• When the compressor electrical circuit is energized,

the start winding current causes the relay to heat

and switch off the start winding circuit.

NOTE: The relay will switch off the start winding

circuit even though the compressor has not started

(as when attempting to re-start after momentary

power interruption).

• The overload protector is designed and calibrated

to open the compressor electrical circuit with locked

rotor run winding current only.

Loading...

Loading...