42

WATER IN THE REFRIGERATION SYSTEM

Even in very small quantities, water in any refrigeration

system can cause the following problems:

• Ice plugs in capillary tubes.

• Copper plating in compressor.

• Reactions with organic materials in systems.

• Corrosion of metals.

R-134a and Ester oil will aggravate the problem of water

in the refrigeration system. Ester oil may react with

water vapor and is hydroscopic (it will absorb water if it

comes in contact with humid air). Water is also more

soluble in R-134a than R-12.

To minimize the water content whenever service work is

performed, the refrigeration system should always be

thoroughly evacuated through process tube adaptors on

both the high and low sides of the system. Evacuation

must be for a minimum of 30 minutes to at least a 29.9

inch (500 micron) vacuum.

VACUUM CHART

Vacuum

Inches Hg.

Microns

Boiling Point

of Water °F

28.940 25000 77.9

29.530 10000 52.0

29.832 4600 32.0

29.882 1000 1.0

29.901 500 -11.2

29.915 150 -32.8

29.917 100 -38.2

29.919 50 -49.0

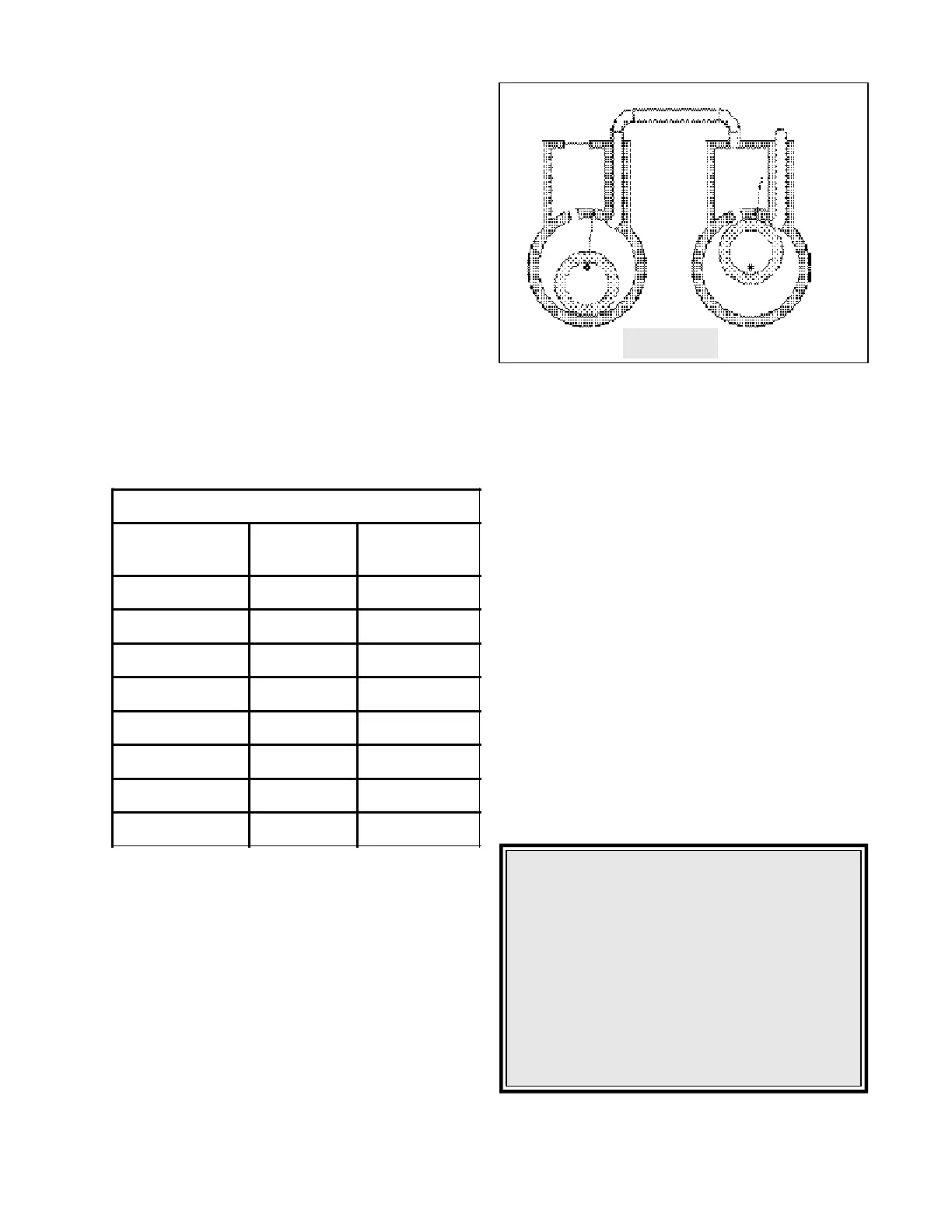

To achieve the required 29.9 inch (500 micron) vacuum,

a properly maintained two-stage vacuum pump in good

condition is required. A two stage pump can reach a

deeper vacuum than a single stage because the exhaust

from the first pumping stage is discharged into the

second pumping stage. This means the second stage

begins pumping at a lower pressure so a lower ultimate

vacuum can be achieved (See 2-Stage Vacuum Pump,

Figure E3).

2-Stage Vacuum Pump

VACUUM PUMP MAINTENANCE

It is absolutely essential to maintain your vacuum pump

according to the manufacturer’s instructions including

required oil changes at the recommended intervals.

Vacuum pump oil should always be changed after

evacuating a contaminated system. Vacuum pump

performance should be checked periodically with a

micron gauge.

Vacuum pump suppliers may or may not recommend

changing the vacuum pump oil to the same type that’s

in the system being evacuated. Some manufacturers

may recommend a vacuum pump that’s dedicated to R-

134a systems.

Robinair has stated that their current and discontinued

vacuum pump models, using mineral oil currently

specified for use in their vacuum pumps, can be used to

evacuate R-134a/Ester oil systems. Robinair also states

that it is acceptable to alternate between evacuating

R-12/mineral oil and R-134a/Ester oil systems without

adversely effecting the vacuum pump’s performance.

For other brands of vacuum pumps, check with the

manufacturer for restrictions and guidelines when using

with R-134a.

CAUTION: If you use a vacuum pump with

mineral oil to evacuate an R-134a system, it is

ABSOLUTELY ESSENTIAL to have a shut-off

valve between pump and your manifold gauge

set as shown in Figure E4. The hand valve

must be closed during all times when vacuum

pump is not operating. This will prevent

migration of mineral oil vapor into R134a/

Ester oil system. If vacuum pump should stop

during evacuation for any reason, the hand

pump shut-off valve must be closed

immediately.

Figure E3

Loading...

Loading...