Torque Values

Enterasys 800-Series Hardware Installation Guide A-11

Torque Values

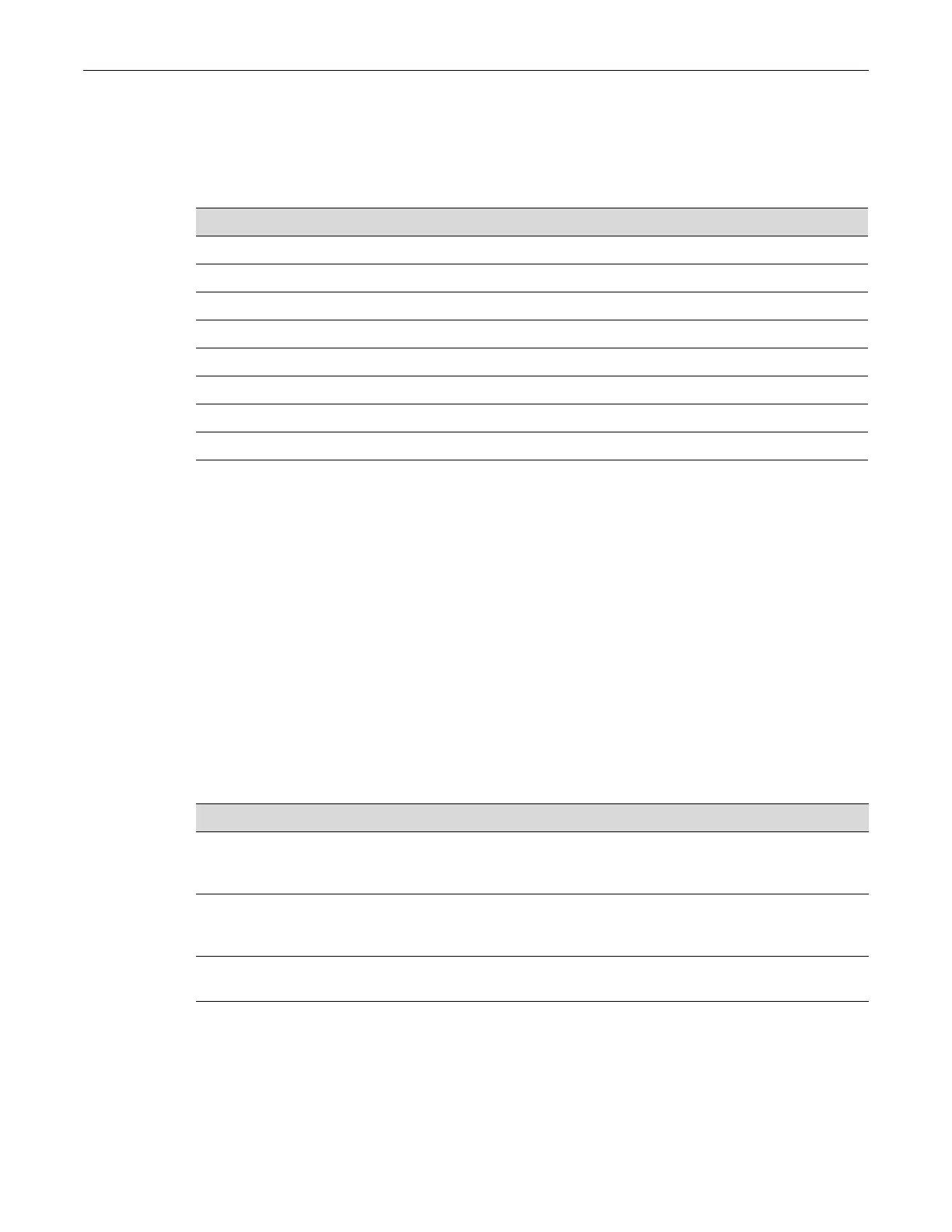

Table A-10 describes the recommended torque values to use when installing the using standard

threaded fastener machine screws and bolts.

Pluggable Transceiver Specifications

For SFP transceiver specifications, refer to the datasheet at

http://www.enterasys.com/products/transceivers-ds.pdf.

Console Port Pinout Assignments

Refer back to Figure 2-28 on page 2-33 for information about console port pinout assignments.

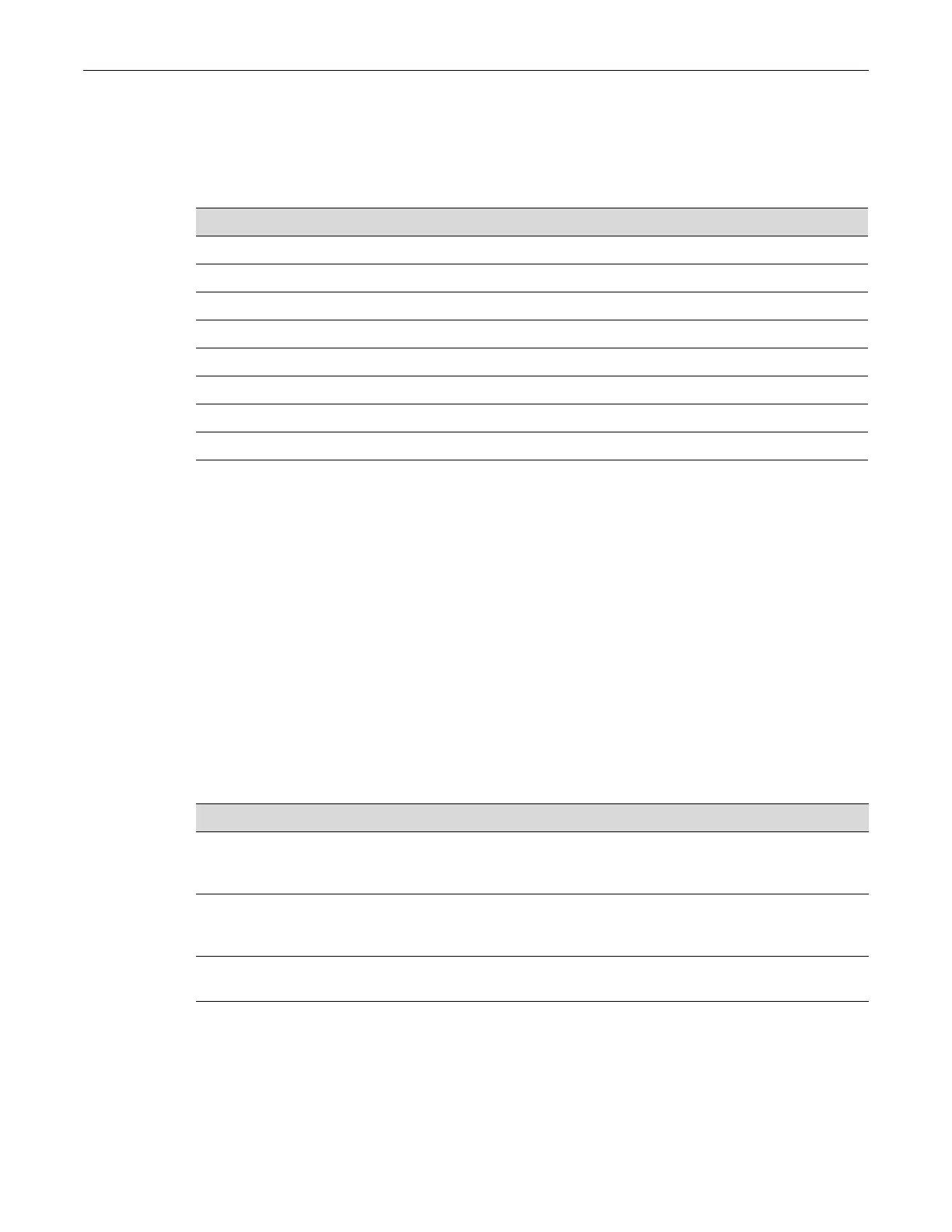

Regulatory Compliance

This product meets the safety, electromagnetic compatibility (EMC), and environmental

requirements listed in Table A-11.

Table A-10 Recommended Torque Values by Screw Size

Screw Size Torque in Pounds Bit Size

English Metric -%5 Nominal +%5

N/A N/A 1.42 1.5 1.57 0

2 – 56 1.5 2.85 3.0 3.15 0

4 – 40 2.5 4.75 5.0 5.25 0/1

6 – 32 3.5 8.55 9.0 9.45 1

8 – 32 4.5 17.10 18.0 18.90 2

10 – 32 5 30.40 32.0 33.60 2

1/4 – 20 6.5 63.65 67.0 70.35 3

Table A-11 Compliance Standards

Regulatory Compliance Standard

Safety UL 60950-1, FDA 21 CFR 1040.10 and 1040.11, CAN/CSA C22.2

No. 60950-1, EN 60950-1, EN 60825-1, EN 60825-2,

IEC 60950-1, 2006/95/EC (Low Voltage Directive)

Electromagnetic Compatibility (EMC) FCC 47 CFR Part 15 (Class A), ICES-003 (Class A), EN 55022

(Class A), EN 55024, EN 61000-3-2, EN 61000-3-3, AS/NZ

CISPR-22 (Class A). 2004/108/EC (EMC Directive)

Environmental 2002/95/EC (RoHS Directive), 2002/96/EC (WEEE Directive),

Ministry of Information Order #39 (China RoHS)

Loading...

Loading...