EPSON Stylus C67/C68/D68 Revision A

ADJUSTMENT Adjustment by Using Adjustment Program 84

5.2.6 PF Adjustment

[Adjustment Procedure]

1. Select PF adjustment in the adjustment program.

2. Click the [Print] button to PF adjustment pattern.

3. Select the pattern that has the smallest displacements in each variable dot,

4. Click the [Input] button to write the adjustment value of checked items.

5. If the smallest displacements is [*] or [**], and click the corresponded button.

6. Check that [*] or [**] is best of the three, input 4 in case of [*] and

-4 in case of [**].

[Treatment procedure for NG product]

Step1) Replace the repaired (replaced) part with new one.

Step2) Print the check pattern, and check the adjustment result.

Step3) If the result is NG level, confirm the installation condition of removed parts

during disassembly.

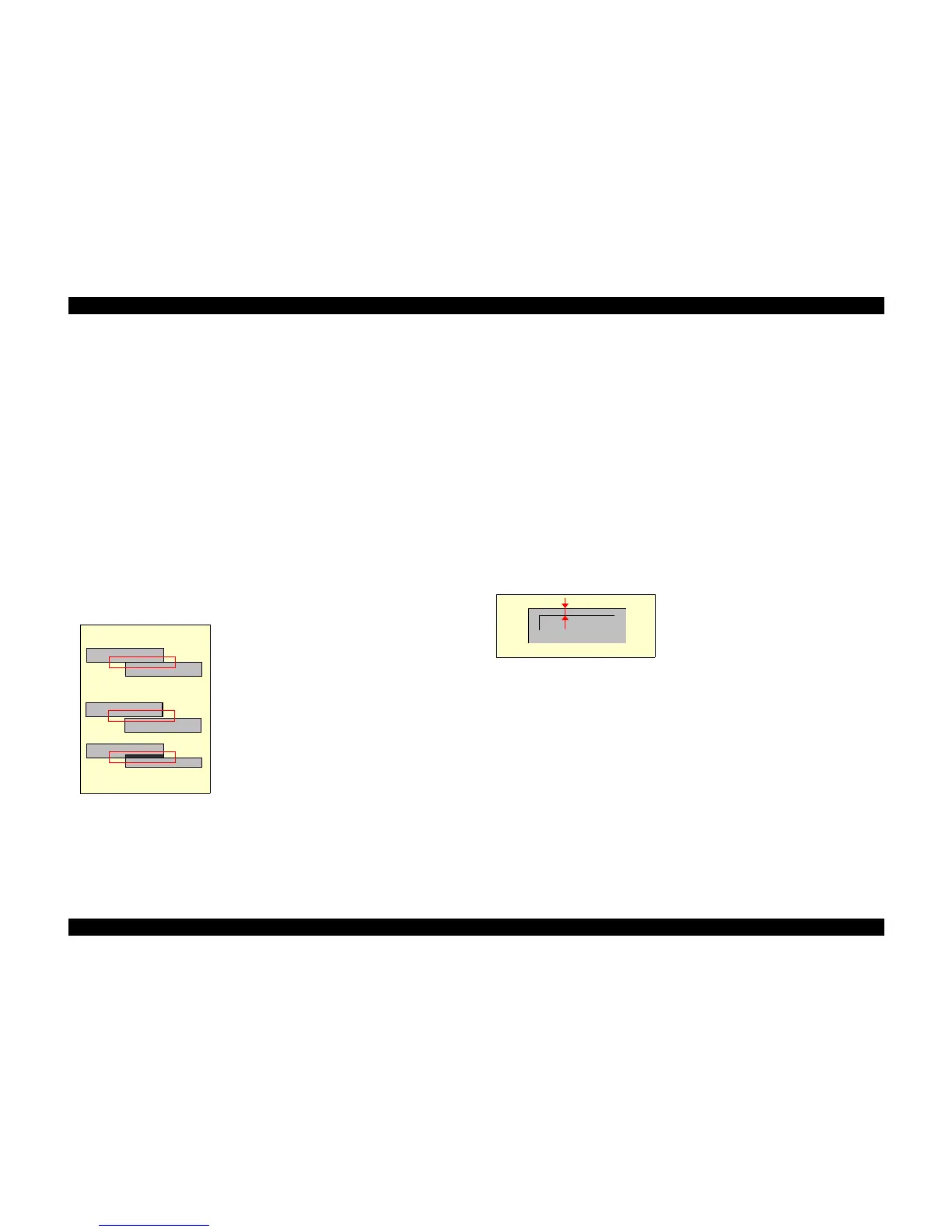

Figure 5-3. PF Adjustment Pattern

5.2.7 First Dot Adjustment

[Adjustment Procedure]

1. Select First Dot adjustment in the adjustment program.

2. Click the [Print] button to print First Dot adjustment pattern.

3. Determine the adjustment value in the shifting direction for the pattern printed on

the left margin. Input can be made in 0.0176mm increments for the adjustment

value of 1.

4. Click the [Input] button to write the adjustment value of checked items.

[Treatment procedure for NG product]

Step1) Replace the repaired (replaced) part with new one.

Step2) Print the check pattern, and check the adjustment result.

Step3) If the result is NG level, confirm the installation condition of removed parts

during disassembly.

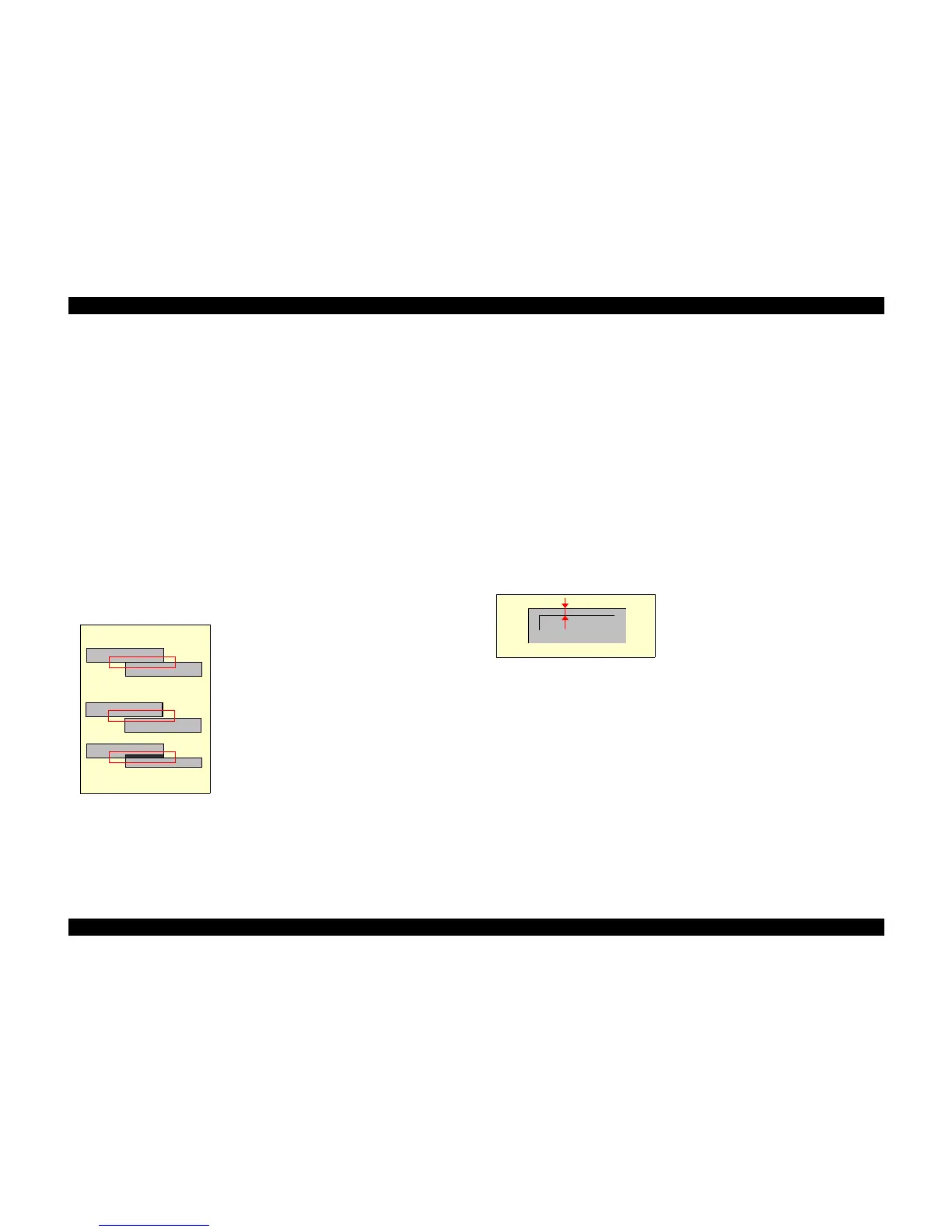

Figure 5-4. First Dot Pattern

OK pattern

NG pattern

[Judging Standard]

- No gap/overlap between short block

pattern and long one.

[Reference:Standard value in manufactory]

- Standard :

±

35µm

[Judging Standard]

- Standard : 3.6

±

1.0 mm away from top edge.

Loading...

Loading...