T3-B T6-B Maintenance 12. Joint #4

T-B series Maintenance Manual Rev.1 107

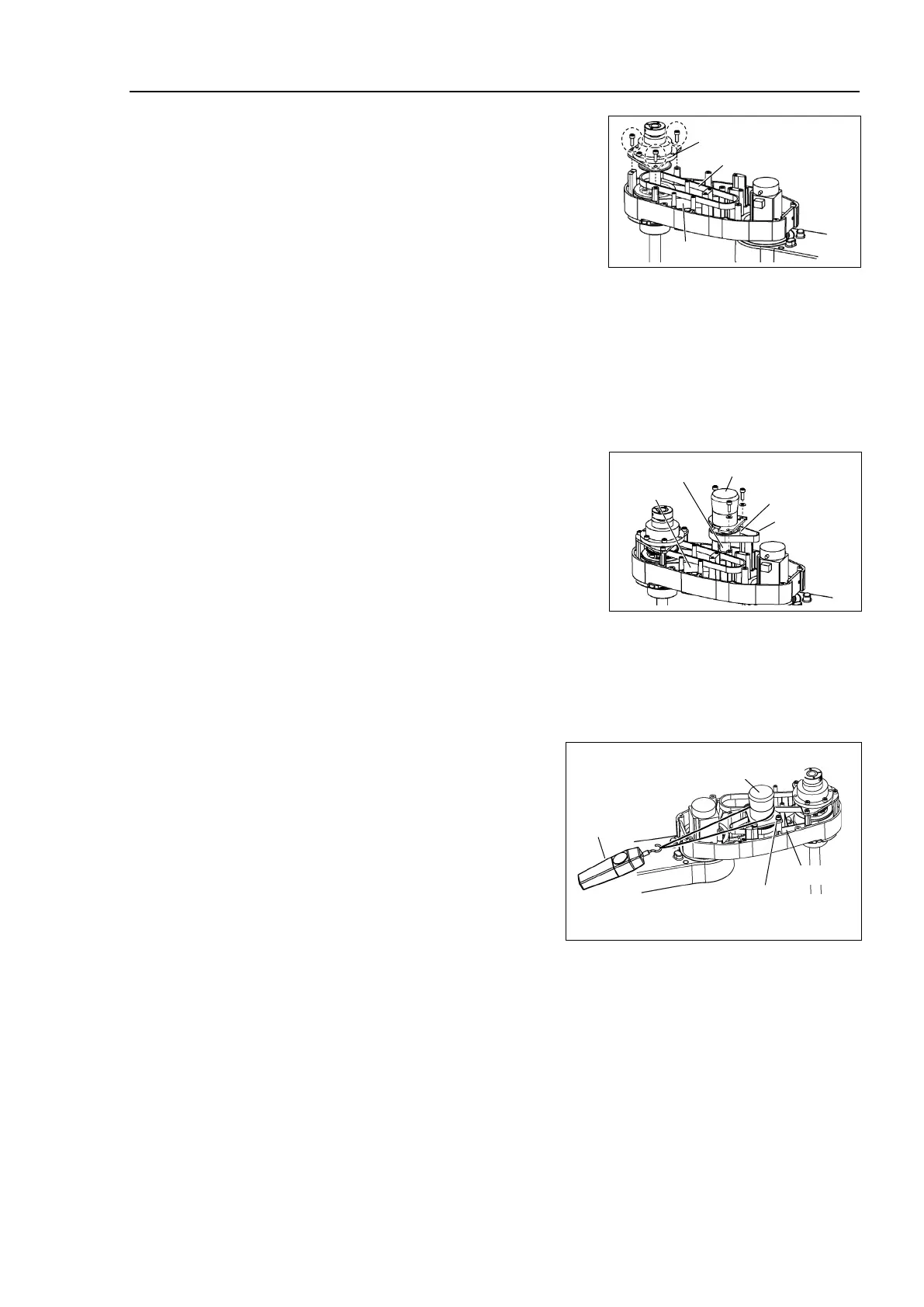

Hold up the spline plate and set a new U2 belt

around the U3 pulley.

grooves of the belt are fit

into those of the pulleys completely.

Hold up the spline plate and set the Z belt around the Z2 pulley.

Make sure the gear grooves of the belt are fit into those of the pulleys

completely.

Secure temporarily the spline plate on the Arm #2 and move the shaft up and down

several times before securing the spline plate.

3-M4x12

Tightening torque: 4 ± 0.2 N·m

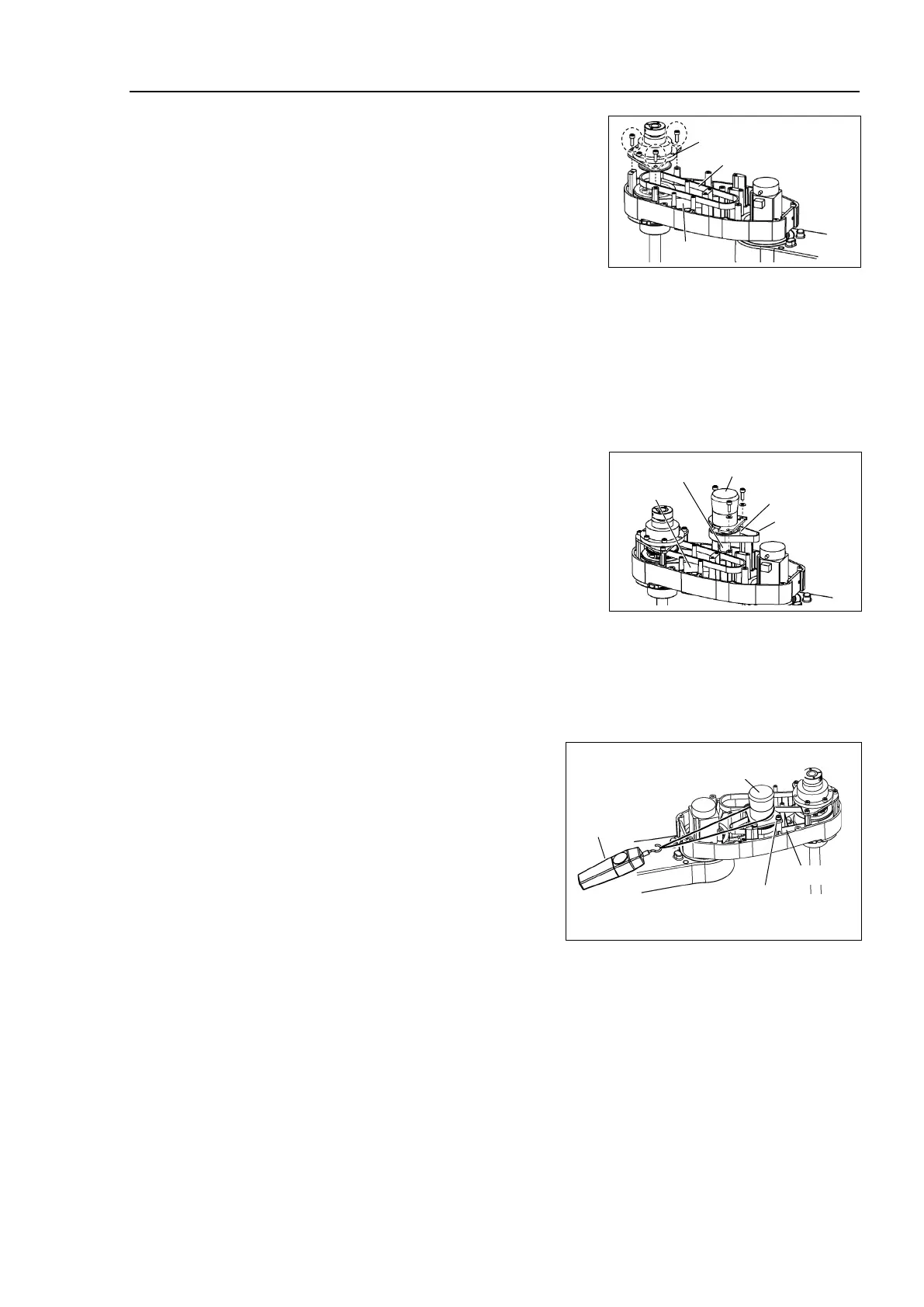

While the U1 belt is set around the large pulley

of Joint #4

intermediate unit, set the U2 belt

inside the arm #2 around the small pulley and

put on the upper surface of the arm #2.

Make sure the gear grooves of the belt are fit

into those of the pulleys.

Joint #4 intermediate

unit

temporarily the Joint #4 intermediate unit by screws.

3-M4x12+M4 washer

Check that the Joint #4 intermediate unit can be moved by hand, and it will not tilt when

pulled. If the unit is secured too loose or too tight, the belt will not have the proper

tensi

on.

Apply the proper tension to U2 belt,

and secure the Joint #4 intermediate

unit.

Set a suitable cord or string around the

part near the plate of the Joint #4

intermediate unit near its mounting

plate. Then, pull the cord using a force

gage or

similar tool to apply the

specified tension shown below.

U2 belt tension:

51 N (5.2 ± 0.75 kgf)

Axial force (when pulling):

102.0 N (10.4 ± 0.75 kgf)

Apply the following torque to secure

the plate.

Tightening torque: 4 ± 0.2 N·m

Joint #4 intermediate unit

Loading...

Loading...