T3-B T6-B Maintenance 18. Error Code Table

146 T-B series Maintenance Manual Rev.1

18. Error Code Table

For details, refer to the following manual.

Status Code / Error Code List

19. Maintenance Parts List

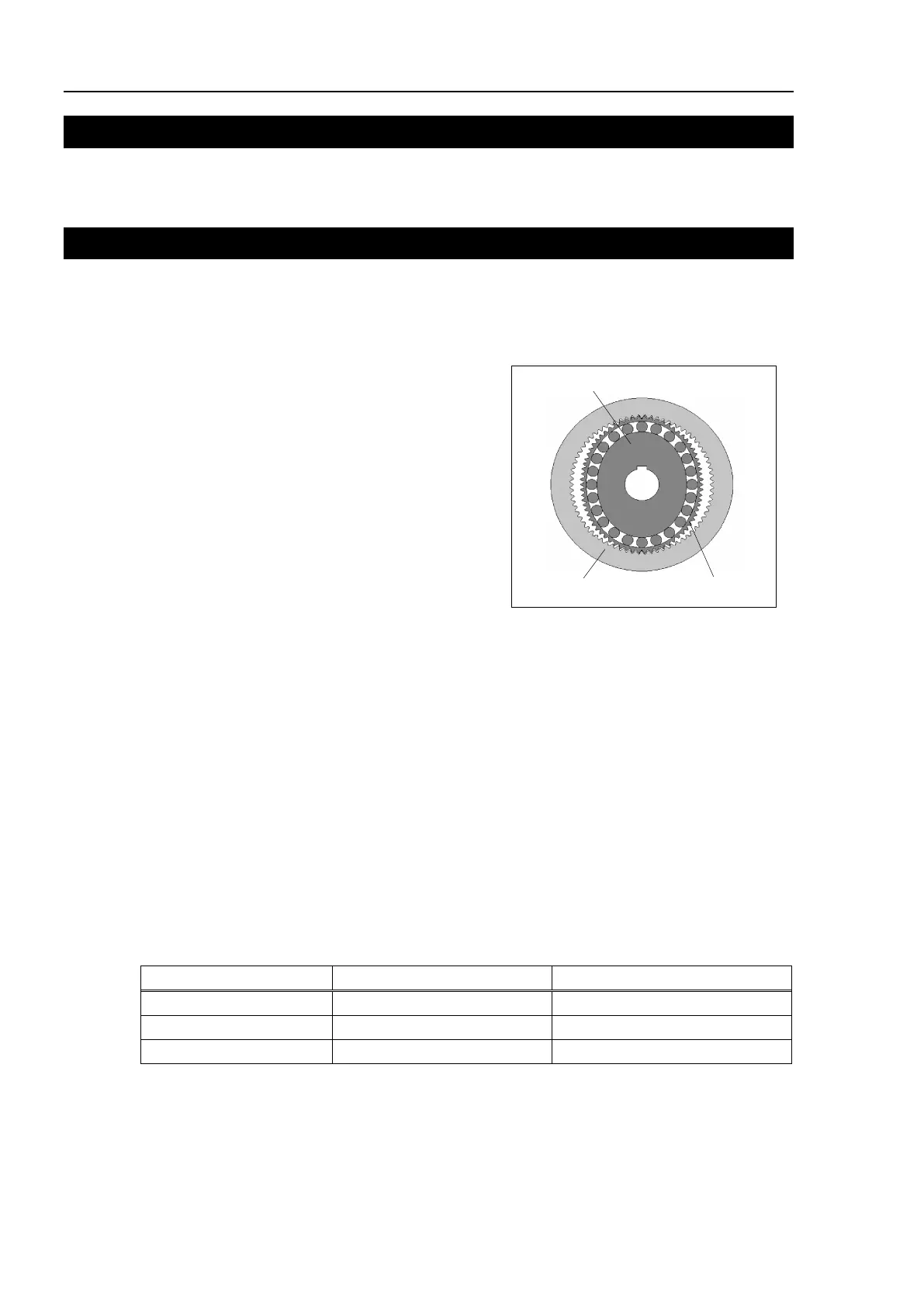

*1 Reduction Gear Unit

A reduction gear unit consists of the following three parts. When replacing the reduction

gear units, be sure to always replace the waveform generator, flexspline, and circular spline

all together as one set.

cam bearing

This waveform generator consists of an

elliptic cam with ball bearings on its outer

circumference.

The inner ring of bearings is secured to the

cam, while the outer ring is capable of

flexible deformation through the ball

bearings.

A thin, elastic, cup-shaped metal body with

gear teeth around the outer circumference of

the opening.

A rigid, ring-shaped body with gear teeth on

the inner circumference. The circular spline

has more teeth than the flex gear does.

Elliptic cam bearing, flex gear, and internal gear are greased. Be careful not to let grease

adhere to clothes.

*2 Regarding purchase of grease and adhesive

Due to the chemicals regulations of individual countries (the UN GHS), we are requesting

our customers to purchase the grease required for maintenance from the manufacturers listed

in the table below as of April 2015.

Regarding purchase of the grease, please contact the following manufacturers. If there is

anything unclear, please contact the supplier of your region.

https://www.nidec-shimpo.co.jp/

* 3 Overhaul

As a rough indication, perform the overhaul (parts replacement) before reaching 20,000

operation hours of the Manipulator.

The operation hours can be checked in EPSON RC+ - [Controller Status Viewer] dialog -

[Motor On Hours].

For details, refer to “2.2 Overhaul (Parts Replacement)”.

Loading...

Loading...