GMV5 Home DC Inverter Multi VRF Units

159

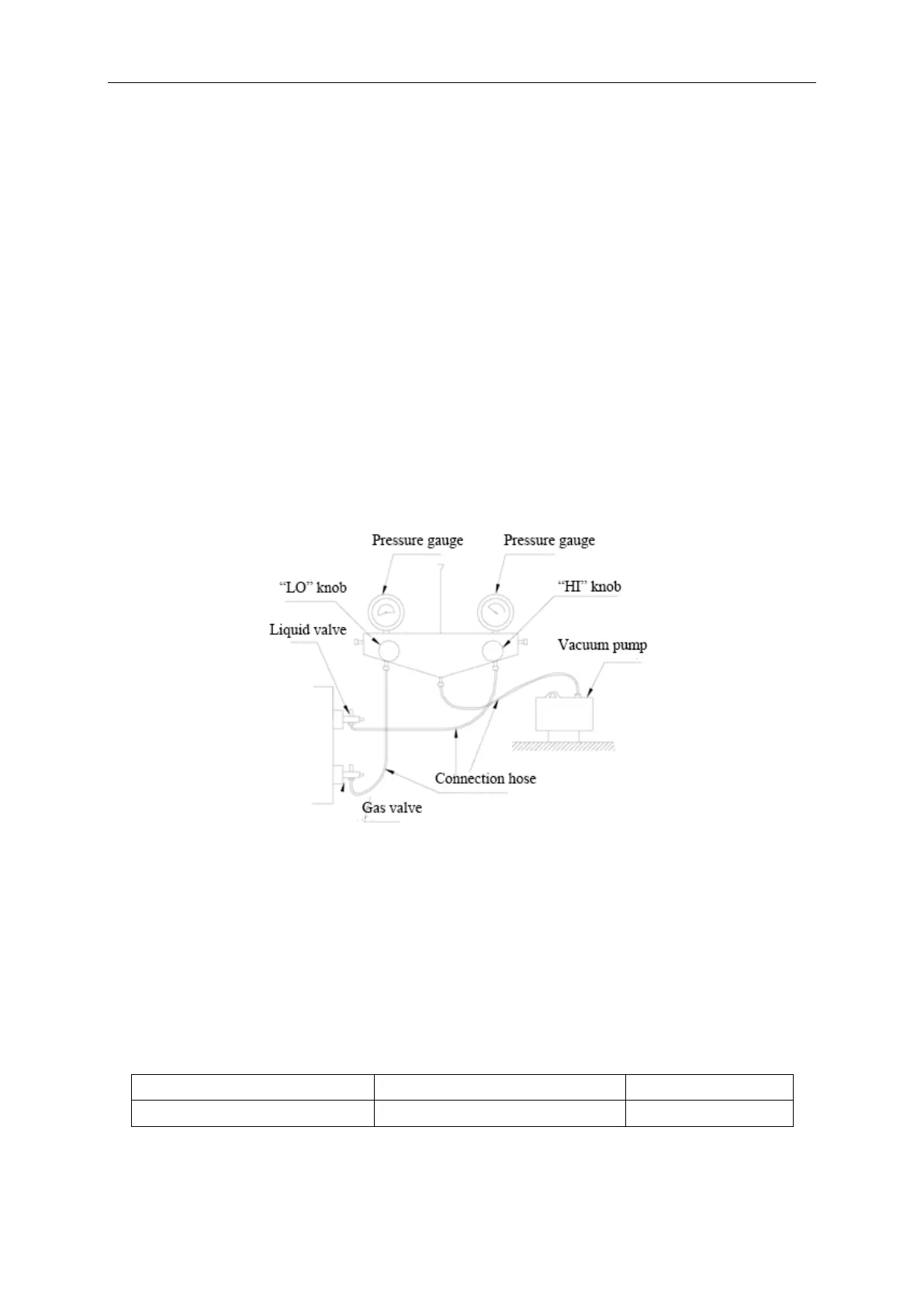

2)Use the perfusing duct to connect the regulator valve and vacuum pump to detection

connectors of the gas pipe valve, liquid pipe valve and high-pressure gas pipe valve.

3)Vacuumize for 4 hours and check whether the vacuum degree reaches -0.1MPa or more. If

not, leakage may exist. Perform leakage check again. If no leakage exists, continue to vacuumize

for 2 hours.

4)If the vacuum degree cannot be kept after vacuumization is performed for twice, there may

be water in the pipe when it is confirmed that no leakage exists. In this case, discharge water by

means of vacuum breaking. Perfuse nitrogen at 0.05MPa to the pipe. Vacuumize for 2 hours and

keep vacuuming for 1 hour. If the vacuum degree of -0.1MPa cannot be reached, repeat this

operation till water is discharged.

5)After vacuumization, turn off the regulator valve and keep for 1 hour. Ensure that the

pressure of the regulator valve does not increase.

9.5.1.4.2 Precautions:

1) Arrange vacuumization from the gas pipe and liquid pipe simultaneously and then arrange

vacuumization from the high-pressure gas pipe.

Check if the gas pipe valve, liquid pipe valve and high pressure gas pipe valves of ODU

connected with IDU and hydro box are fully closed.

As shown below, discharge air with vacuum pump from the gas pipe valve, liquid pipe valve

and high pressure gas pipe valves of ODU. If all IDUs and ODU are energized, the unit can enter

vacuum pumping mode of IDUs, ensuring that the valves of IDU and hydro box are open.

2)Turn off the valve before powering off the vacuum pump.

3)Keep vacuuming for 2 hours. The vacuum meets the requirement if the pressure displayed

by the vacuum gauge does not increase.

9.5.2 Insulation for the refrigerant system pipe

9.5.2.1 Insulation materials

Use closed-cell foam insulation materials with flame retardant grade of B1.

The heat conductivity is not greater than 0.035 w/(m·k) when the average temperature is 0°C.

9.5.2.2 Thickness of the insulation layer

External Diameter of the Pipe (mm)

Thickness of the Insulation Layer (mm)

Use sunblock, anti-weathering, and non-cracking insulation materials for outdoor pipes.

9.5.2.3 Procedure of insulation

1)Select insulation materials based on design requirements.

Loading...

Loading...