12 - Fault finding

69

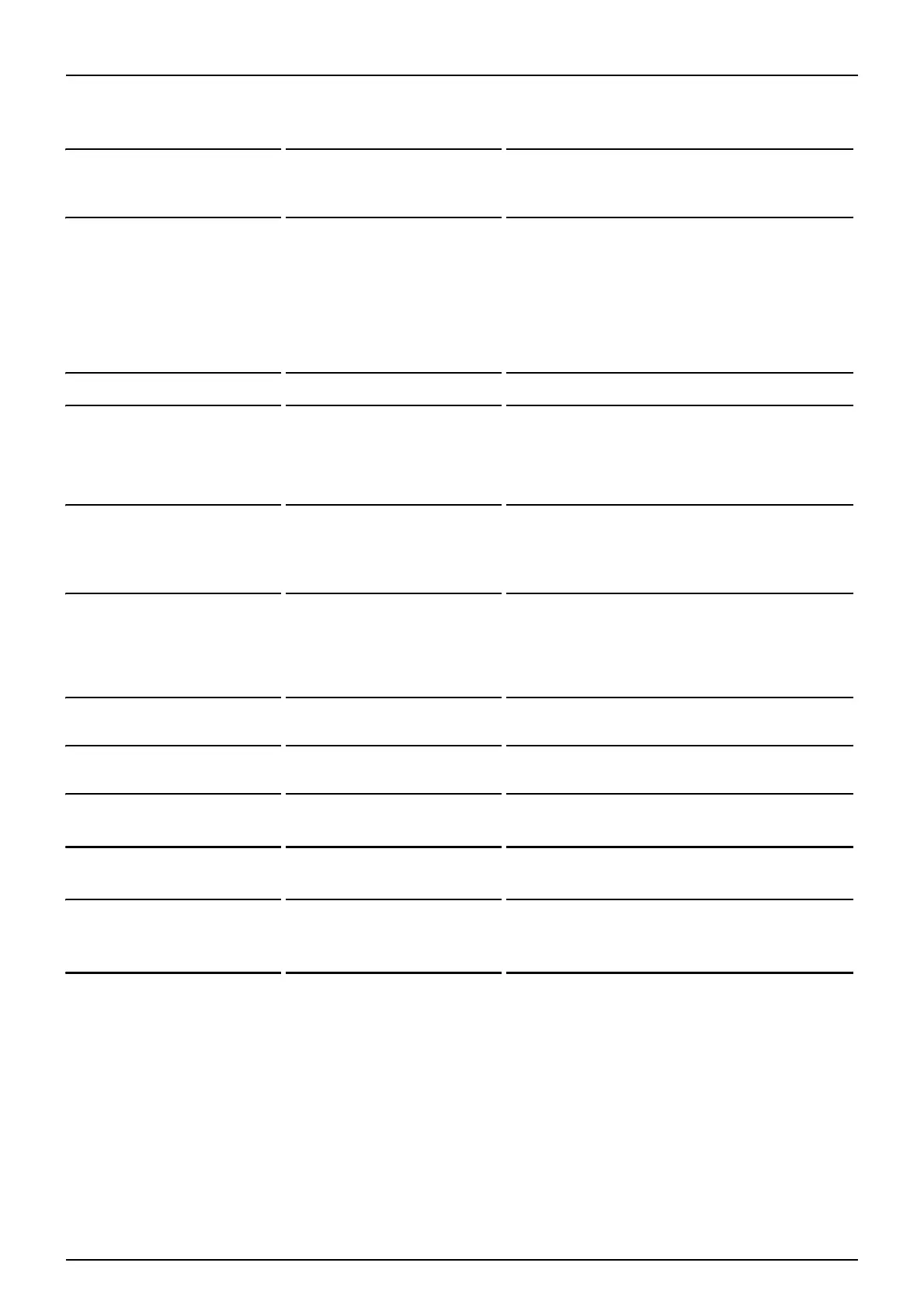

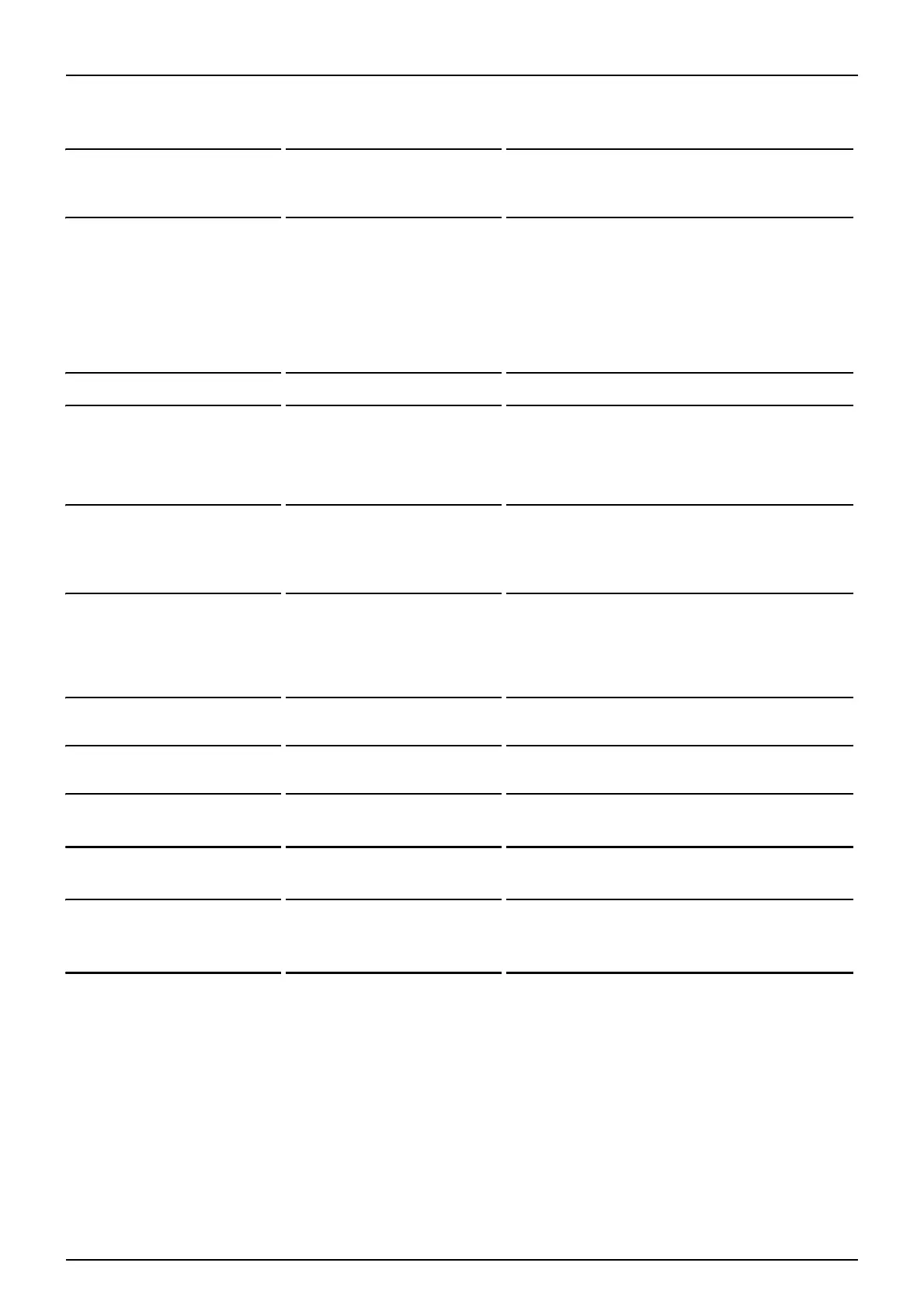

Mechanical faults

FAULT PROBABLE CAUSE CONTROL/REMEDY

No speed readout. Incorrect speed sensor location chosen. Select the correct sensor on Sprayer, Tractor or Radar in menu [3.1.1 ,

3.1.2 or 3.1.3].

Defect sensor or cable. Check sensor using menu [4.5.2 Speed].

Error message that fuse is active. Short circuit in system. The Spray box has 3

thermal fuses:

Fuse 1 = Section valves to left side of centre

and centre switch.

Fuse 2 = Section valves to right of centre

switch.

Fuse 3 = Short circuit in options and

pressure regulation.

Turn power OFF and locate problem.

When fuses has cooled down the system can be powered on again.

Error message “Low voltage”. Voltage below 9 Volts. Check battery and connections.

Speed readout not stable. Perforated wheel transducer plate fitted

back the front.

Speed transducer set to close to upper or

lower sides of perforated wheel sensor

plate.

Relocate transducer.

Attempt to release lock, but no “release”

signal from lock sensor.

No hydraulic pressure. No hydraulic pressure.

Misadjusted lock sensor. Misadjusted lock sensor.

Mechanical defect. Mechanical defect.

Attempt to lock, but no “lock” signal on

sensor input.

Lock sensor misadjusted. Adjust lock sensor gap to max. 5 mm.

Mechanical defect prevents lock to

penetrate hole.

Change defected parts.

Misadjusted rear angle sensor. Adjust rear angle sensor to center.

Lock is detected released unintentionally. Poor lock sensor adjustment. Lock cylinder

fallen off.

Re-fit new lock cylinder. Adjust lock sensor gap to max. 5 mm.

Lock is detected released. Hydraulic pressure established. Misadjusted

lock sensor.

Adjust lock sensor gap to max. 5 mm.

Lock is detected locked unintentionally. Missing hydraulic pressure on lock cylinder. Check pressure from tractor.

Misadjusted lock sensor. Adjust sensor gap to lock to max. 5 mm.

No lock release when hydraulic pressure is

established, and the HC 5500 is powered up.

Hydraulic pressure hoses P and T are turned

around.

Turn hydraulic pressure around.

T = blue P = red.

Power to Jobcom. Power supply not sufficient. The cable from the battery to Jobcom has to be 6 square millimetres.

The power cable to the Jobcom has to be a

unbroken power line from the battery.

Fit 72266300 tractor power cable.

The fuse on the cable has to be 25A.

Rear angle sensor alarm. In menu 4.7 the rear angle sensor will read

app. 0.02 Volt.

Check 10A fuse on DAH PCB in the Jobcom.

Check sensor cables for damage.

Loading...

Loading...