MAINTENANCE

7-81

10

Check Air Conditioner --- daily

1. Check pipe connections for refrigerant gas leakage.

If oil seepage is found around pipe connections, it indi-

cates possible gas leakage.

2. Check the condenser.

If the condenser fins become clogged with dirt or insects,

the cooling effect will be decreased. Be sure to keep it

clean at all times. (Refer to “Clean Radiator Core” in Main-

tenance Section.)

3. Check the compressor

After operating the air conditioner for 5 to 10 minutes,

touch the high-pressure side and low-pressure side pipes

with your hand. If normal, the high-pressure side pipe will

be hot, and the low-pressure side cold.

4. Check mounting bolts for looseness.

Confirm that the compressor mounting bolts and other

mounting/fastening bolts are securely tightened.

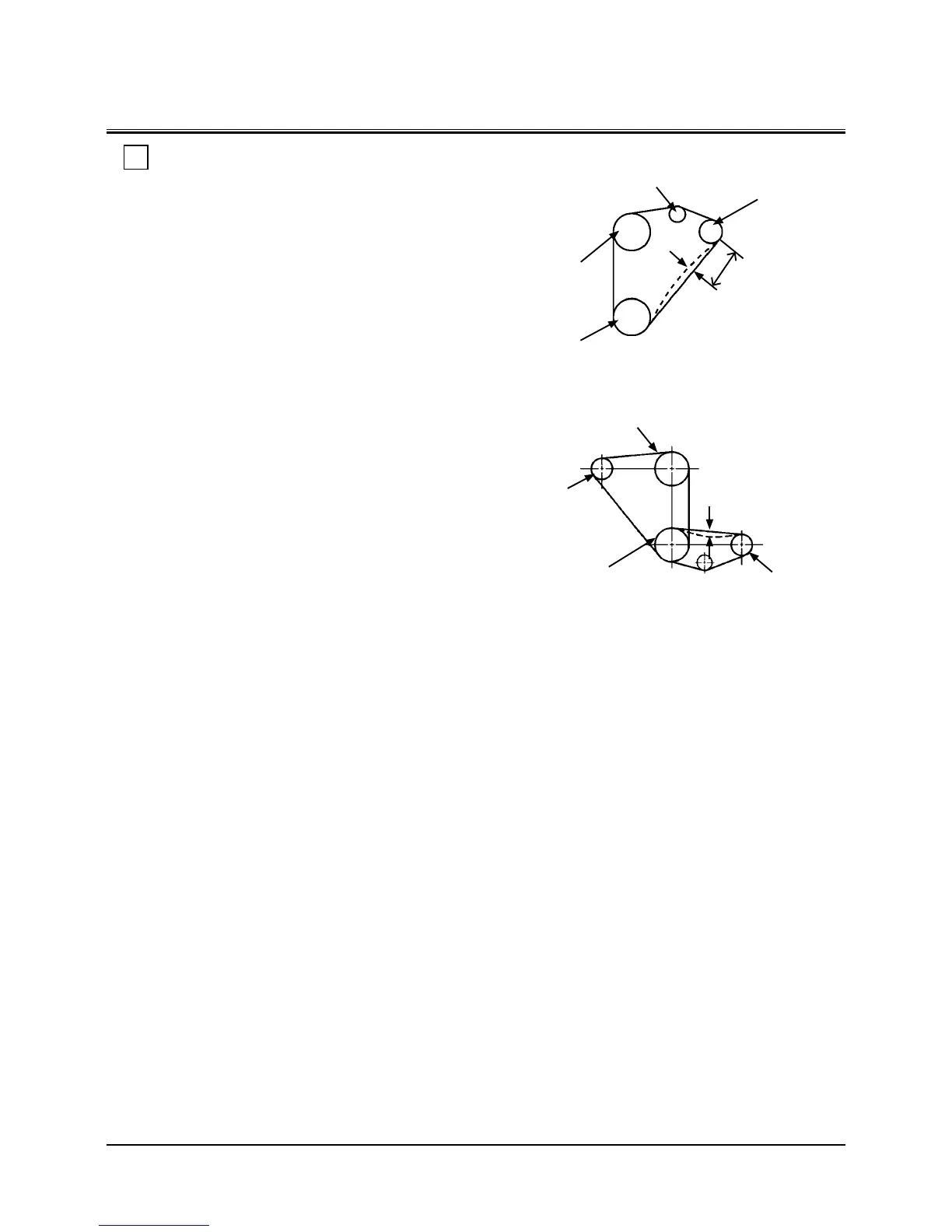

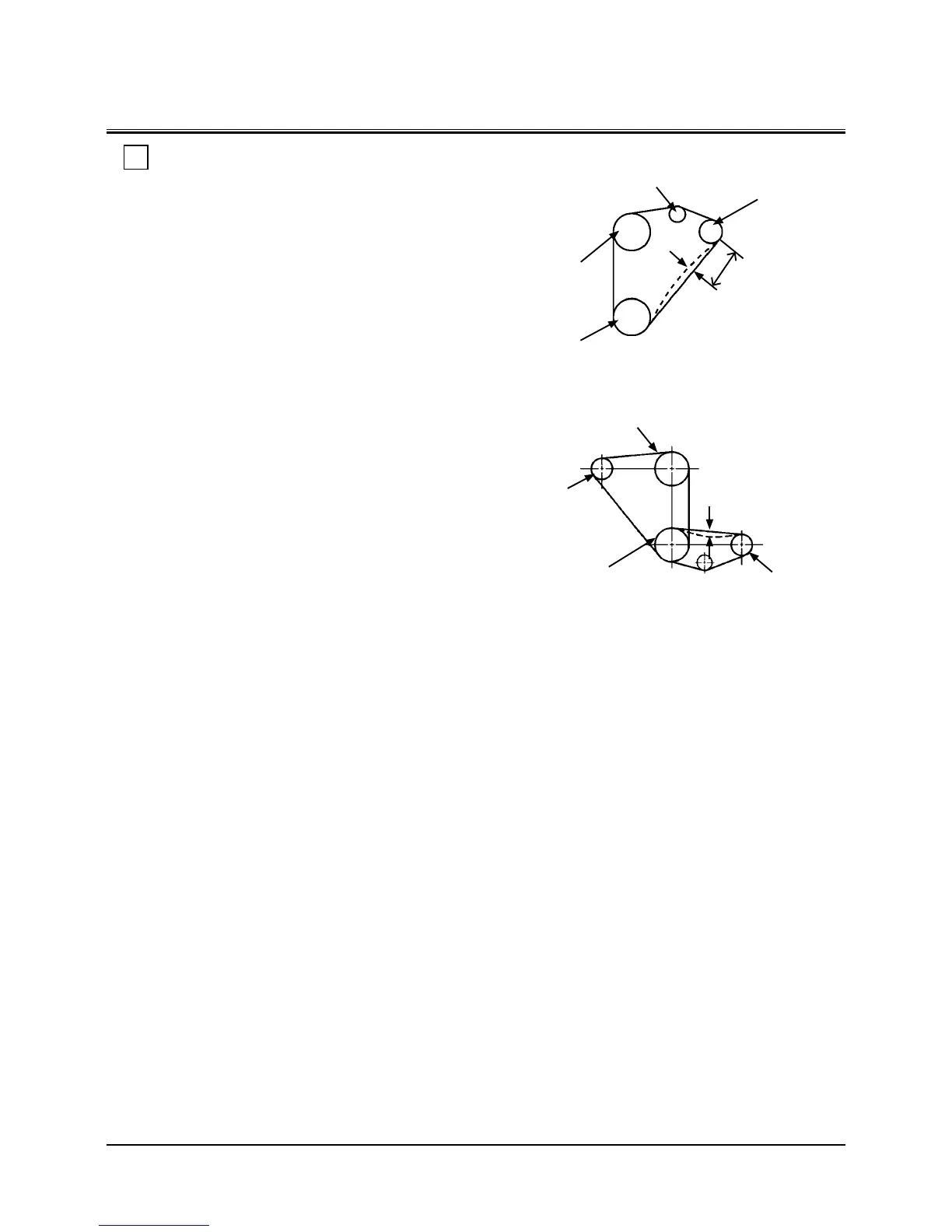

5. Inspect belt, check and adjust tension.

Visually check the compressor and fan belts for wear.

Check and adjust belt tension, referring to the illustration

(right).

If cool air does not come out, or any other abnormalities are

found in air conditioner system, see your authorized dealer

for inspection.

M1U1-07-086

Fan Pulley

Crank Pulley

Compressor Pulley

Tension Pulley

8 to 12 mm (0.32 to 0.47 in)

98 N (10 kgf, 22 lbf)

M1GR-07-007

Fan Pulley

Crank Pulley

Compressor Pulley

Alternator Pulley

5 to 6 mm (0.2 to 0.24 in)

98 N (10 kgf, 22 lbf)

150 mm

ZX200-3, 270-3 , 330-3 Class

ZX120-3, 180-3 Class

Loading...

Loading...