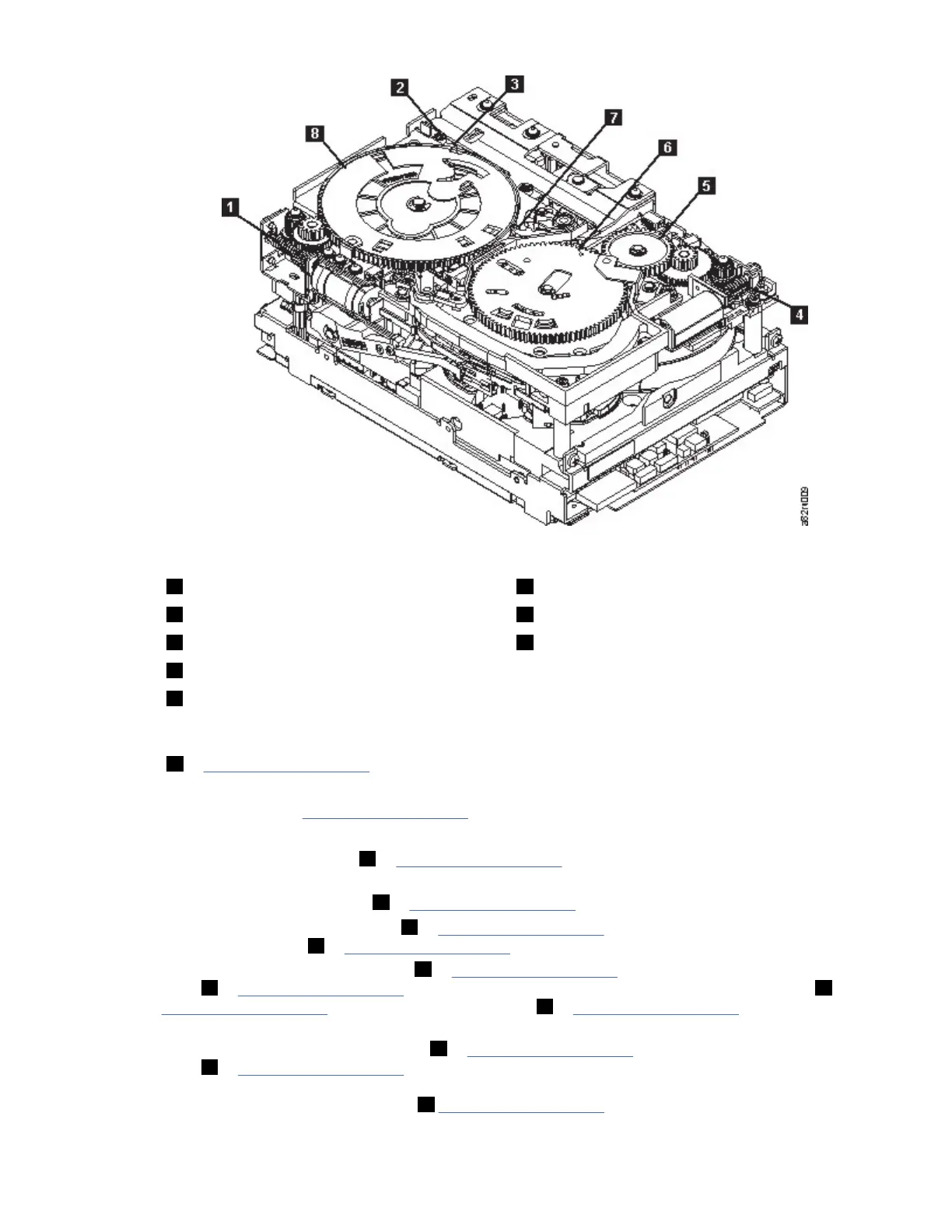

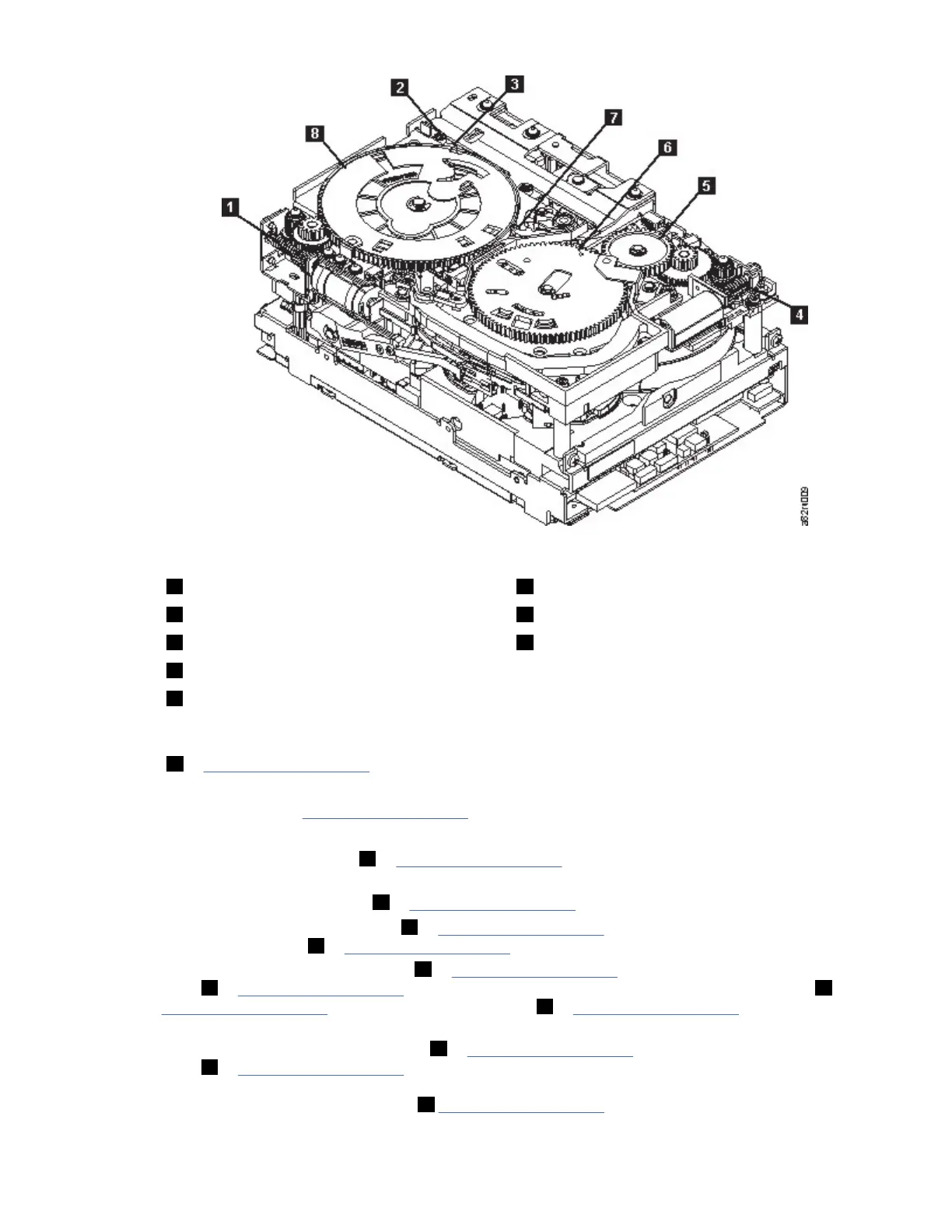

Figure 123. Drive with cover removed to reveal gear train.

1 Loader motor worm gear 6 Threader mechanism gear

2 Cartridge loader tray guide bearing 7 Lever

3 Rotator stub 8 Loader mechanism gear

4 Threader motor worm gear

5 Threader intermediate gear

7. As the tape leader block assembly (LBA) is secured in the cartridge, you hear the LBA retention spring

clips click into place. If you do not hear the click, continue rolling until the threader motor worm gear

(4 in Figure 123 on page 237) stops. The LBA is in the correct position.

Note: Be sure to keep tension on the tape as the LBA is drawn into the cartridge by using a hex

wrench as shown in Figure 122 on page 236.

8. Notice these mechanisms:

a) Loader mechanism gear (6 in Figure 123 on page 237) nearest the front of the drive that actuates

the cartridge loader mechanism.

b) Position of the rotate stub (3 in Fig

ure 123 on page 237

).

c)

Front loader motor worm gear (

1 in Fig

ure 123 on page 237

). Rotating this gear allows the loader

mechanism g

ear (

8 in Fig

ure 123 on page 237

) to turn.

9.

Rotate the loader motor worm gear (

1 in Fig

ure 123 on page 237

) to turn the threader mechanism

g

ear (

6 in Fig

ure 123 on page 237

) counterclockwise. Continue turning until the rotator stub (3 in

Fig

ure 123 on page 237

) loses contact with the lever (7 in Fig

ure 123 on page 237

). This action

r

eleases the LBA leader pin.

10. Rotate the threader motor worm gear (

4 in Fig

ure 123 on page 237

) to turn the threader mechanism

g

ear (

6 in Fig

ure 123 on page 237

) counterclockwise. This action moves the LBA out of the cartridge

and pas

t the read/write head. Stop this rotation when the LBA is near the tape guide roller nearest

the rear of the drive that is shown as

1 Fig

ure 124 on page 238

.

IBM Condential

Appendix I. Manual cartridge removal procedure237

Loading...

Loading...