5.1.3 Materials in the cooling cicuit

• For all metallic elements in contact with the coolant (electrolyte) in the cooling cir-

cuit, select a material which generates a low voltage difference to the heat sink

(see electrochemical voltage series). This prevents contact corrosion and/or pitting

corrosion.

• Other materials must be examined in each case before employment.

• Thespeciccaseofapplicationmustbecheckedbythecustomerintuningofthe

completecoolingcircuitandmustbeclassiedaccordingtotheusedmaterials.

• With hoses and seals take care that halogen-free materials are used.

• For liquid coolers with stainless steel tube, we recommend the use of stain-

less steel or nickel plated brass cable glands.

• For liquid coolers as extrusion casting heat sink, we recommend the use of

aluminium or ZnNi coated steel tubes.

ATTENTION

A liability for occuring damages by wrongly used materials and from

this resulting corrosion is not taken over!

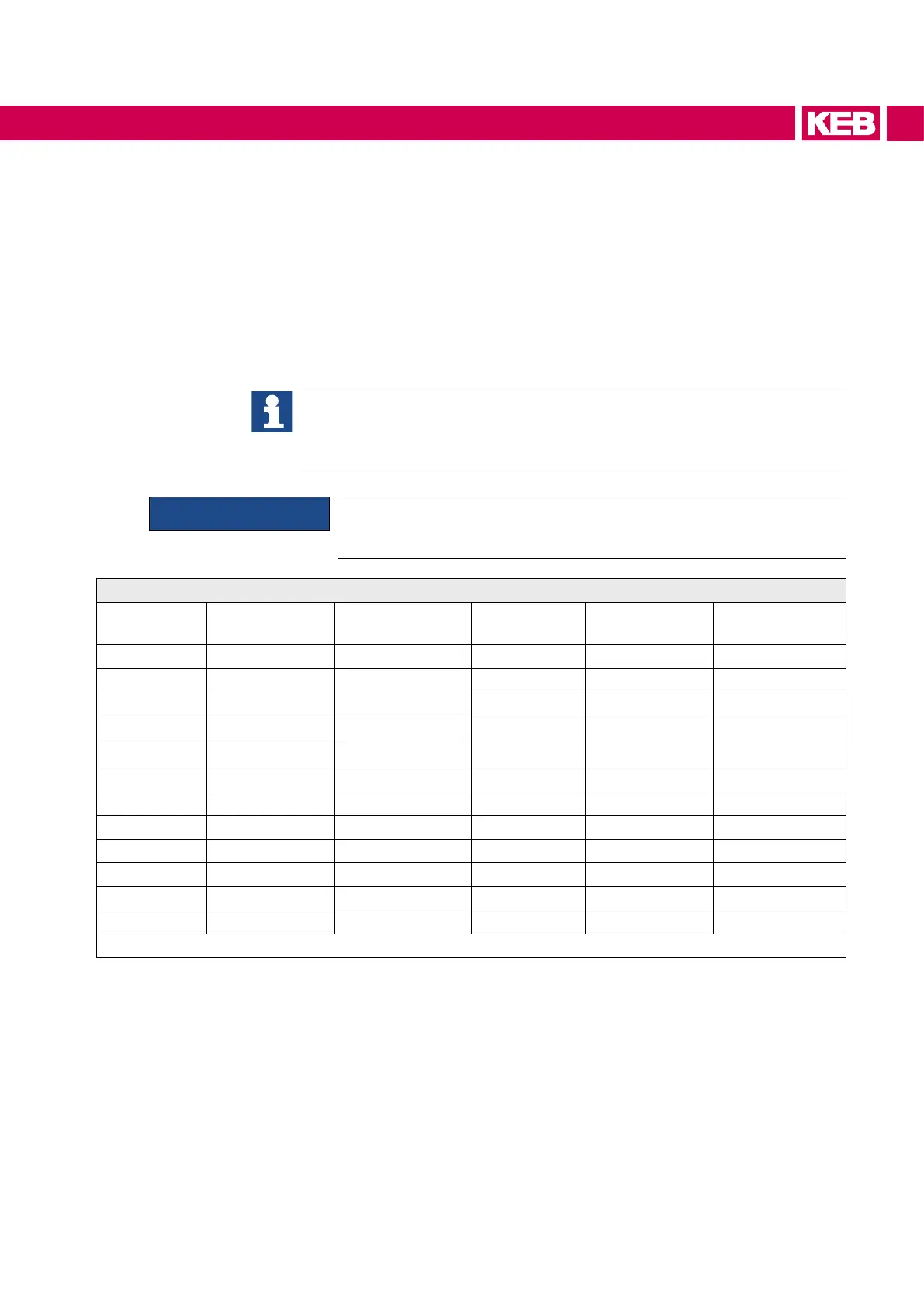

Electro-chemical voltage series / standard potentials against hydrogen

Material generated Ion Standard poten-

tial

Material generated Ion Standard poten-

tial

Lithium Li

+

-3.04 V Cobald Co

2+

-0.28 V

Potassium K

+

-2.93 V Nickel Ni

2+

-0.25 V

Calcium Ca

2+

-2.87 V Tin Sn

2+

-0.14 V

Sodium Na

+

-2.71 V Lead Pb

3+

-0.13 V

Magnesium Mg

2+

-2.38 V

Iron Fe

3+

-0.037 V

Titan Ti

2+

-1.75 V Hydrogen 2H

+

0.00 V

Aluminium Al

3+

-1.67 V Copper Cu

2+

0.34 V

Manganese Mn

2+

-1.05 V Carbon C

2+

0.74 V

Zinc Zn

2+

-0.76 V Silver Ag

+

0.80 V

Chrome Cr

3+

-0.71 V Platinum Pt

2+

1.20 V

Iron Fe

2+

-0.44 V Gold Au

3+

1.42 V

Cadmium Cd

2+

-0.40 V Gold Au

+

1.69 V

Table 15: Electro-chemical voltage series / standard potentials against hydrogen

55

OPERATION OF LIQUID-COOLED DEVICES

Loading...

Loading...