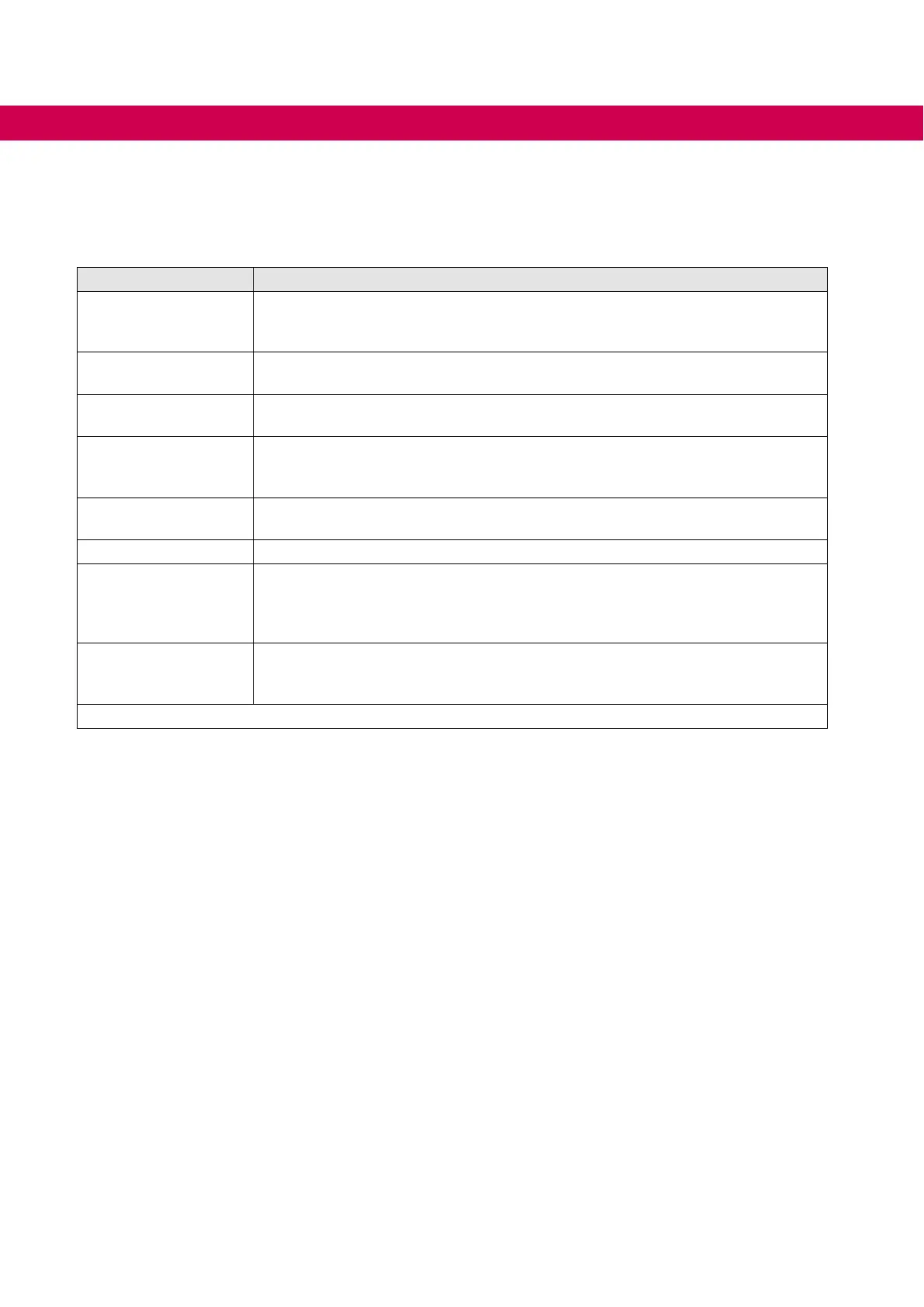

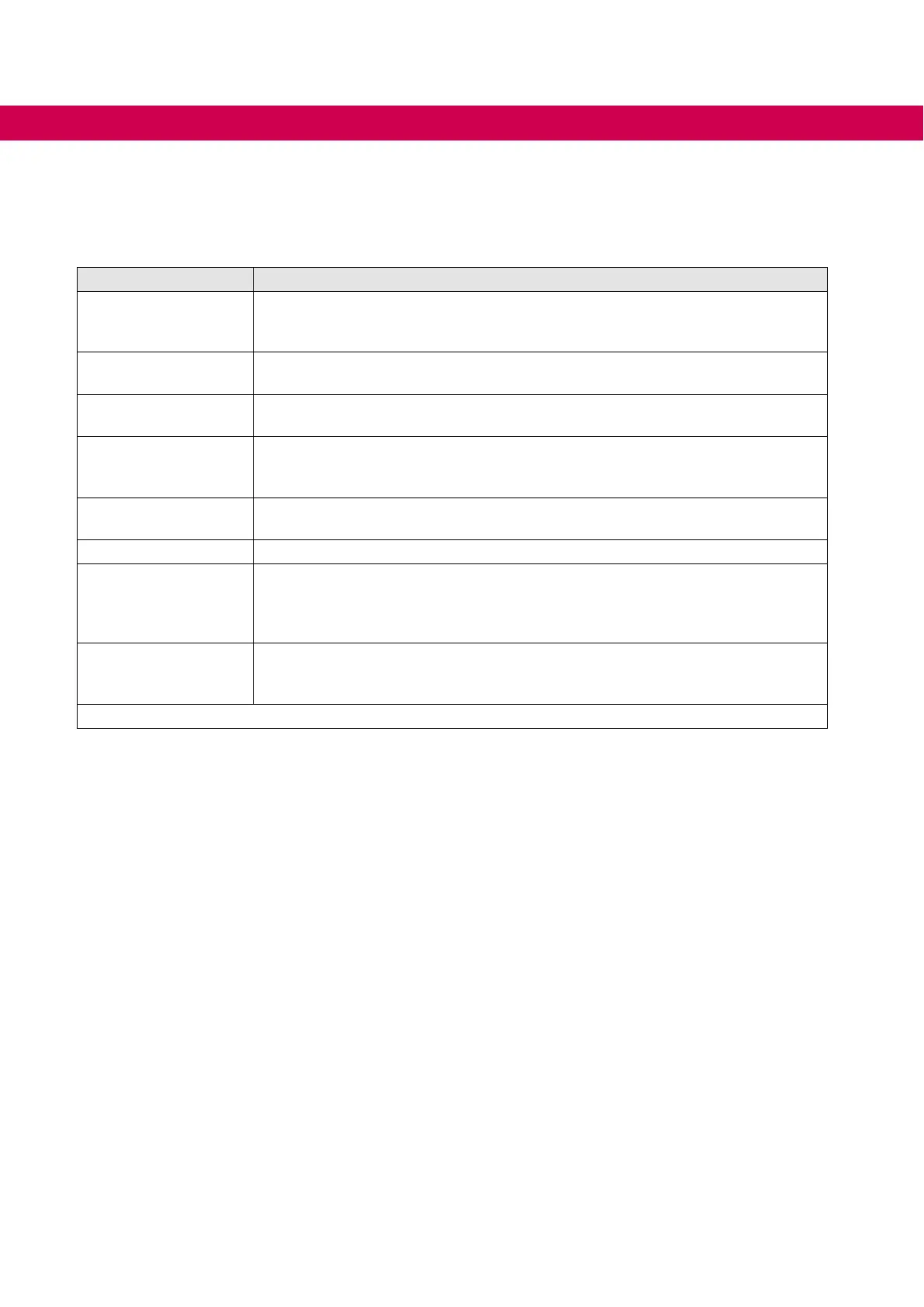

5.1.4 Requirements on the coolant

The requirements on the coolant are depending on the ambient conditions, as well as

from the used cooling system. General requirements on the coolant:

Requirements Description

Suspended particles

The size and the proportion of suspended particles in the cooling water should

not exceed the following values:

<100μm<10mgperliter.

pH-value

Aluminum is particularly corroded by lixiviums and salts. The optimal pH value for

aluminum should be in the range of 7,5… 8.0.

Abrasive substances

Abrasive substances as used in abrasive (quartz sand), clogging the cooling

circuit.

Copper cuttings

Copper cuttings can attach the aluminum and this leads to a galvanic corrosion.

Copper should not be used together with aluminum due to electro-chemical volt-

age difference.

Hard water

The cooling water may not cause scale deposits or loose excretions. The total

hardness should be between 7...20 °dH, the carbon hardness at 3...10 °dH.

Soft water Soft water (< 7 °dH) corrodes the material.

Frost protection

An appropriate antifreeze must be used for applications when the heat sink or the

coolant is exposed temperatures below zero. Use only products of one manufac-

turer for a better compatibility with other additives.We recommend the antifreeze

AntifrogenN from the company Clariant with a maximum volume fraction of 52 %.

Corrosion protection

Additives can be used as corrosion protection. In combination with frost protection

the corrosion protection must have a concentration of 20…25 Vol %, in order to

avoid a change of the additives.

Table 16: Requirements on the coolant

56

OPERATION OF LIQUID-COOLED DEVICES

Loading...

Loading...