TP-7070 7/1880 Section 3 Scheduled Maintenance

3.6 Lubrication System

3.6.1 Oil Change

The engine oil change interval varies for different

engines, applications, and oil type. Identify the following

for your application and then refer to the Engine

Operation and Maintenance Manual for oil change

intervals and oil specifications.

D Engine model. See the engine nameplate or the

generator set specification sheet to identify the

engine.

D Engine oil type (category 1, 2, 3). See the engine

Operation Manual for definitions.

D Generator set engine type (fuel-optimized or

emission-optimized). Generator set models with a -F

in the model designation are fuel-optimized.

D Generator set application (standby, p rime, or

continuous).

Note: Change both the oil filters and centrifugal oil filter

(if applicable) during the oil change.

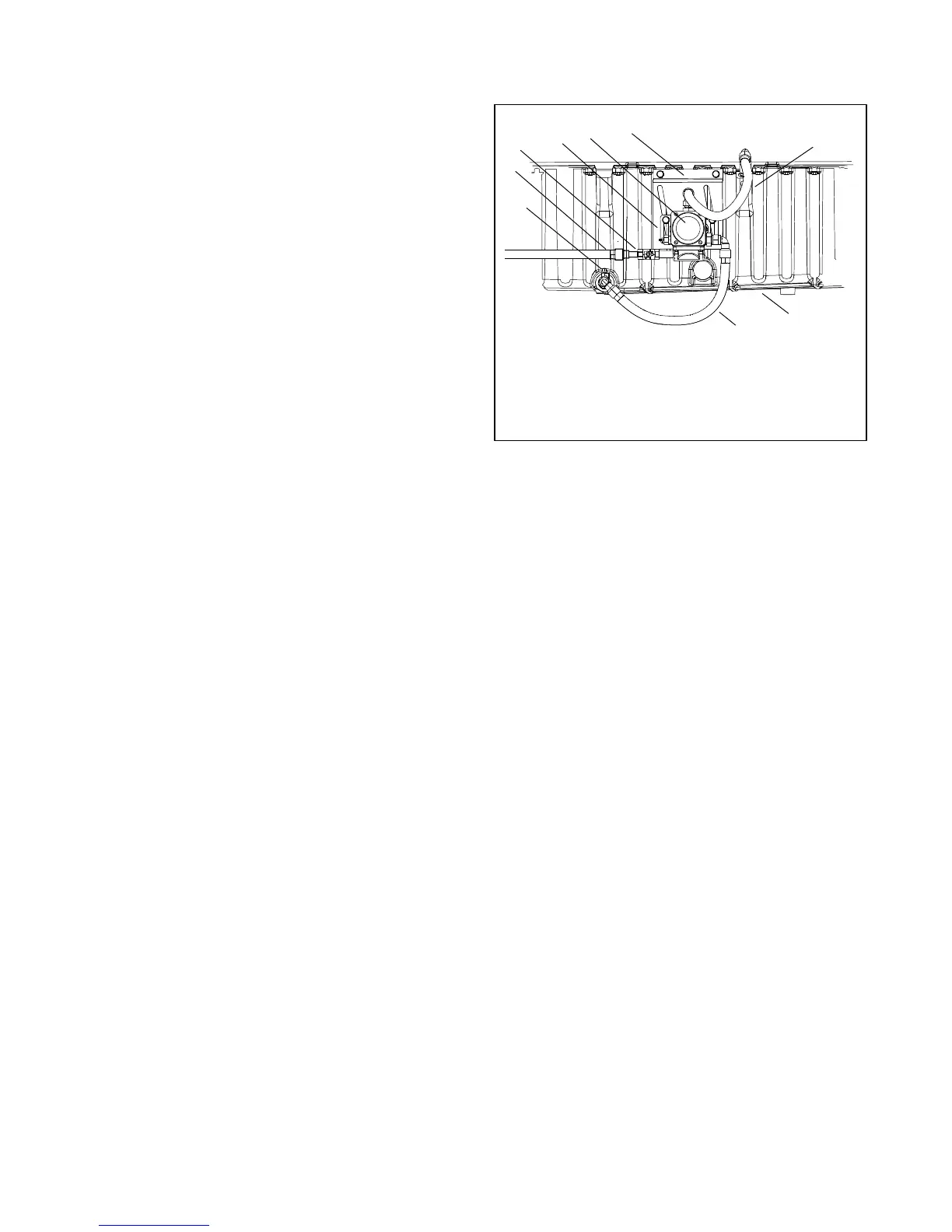

3.6.2 Automatic Oil Replenishment

System (Optional Kit)

1. Shutoff valve

2. Regulator supply line

(inlet port)

3. Shutoff valve

4. Oil level regulator

5. Sight glass

6. Bracket

7. Vent line

8. Oil pan

9. Engine supply line

10404000145-KA

8

6

7

9

5

1

3

2

4

Figure 3-5 Automatic Oil Replenishment System

The oil replenishment system typically works with an oil

reservoir to maintain a constant oil level in the engine

crankcase. As the oil level in the crankcase drops, the

valve inside the oil level regulator opens to supply fresh

oil from the oil reservoir.

Note: The pressure-equalizing vent line between the oil

regulator and the engine prevents positive or

negative crankcase pressure.

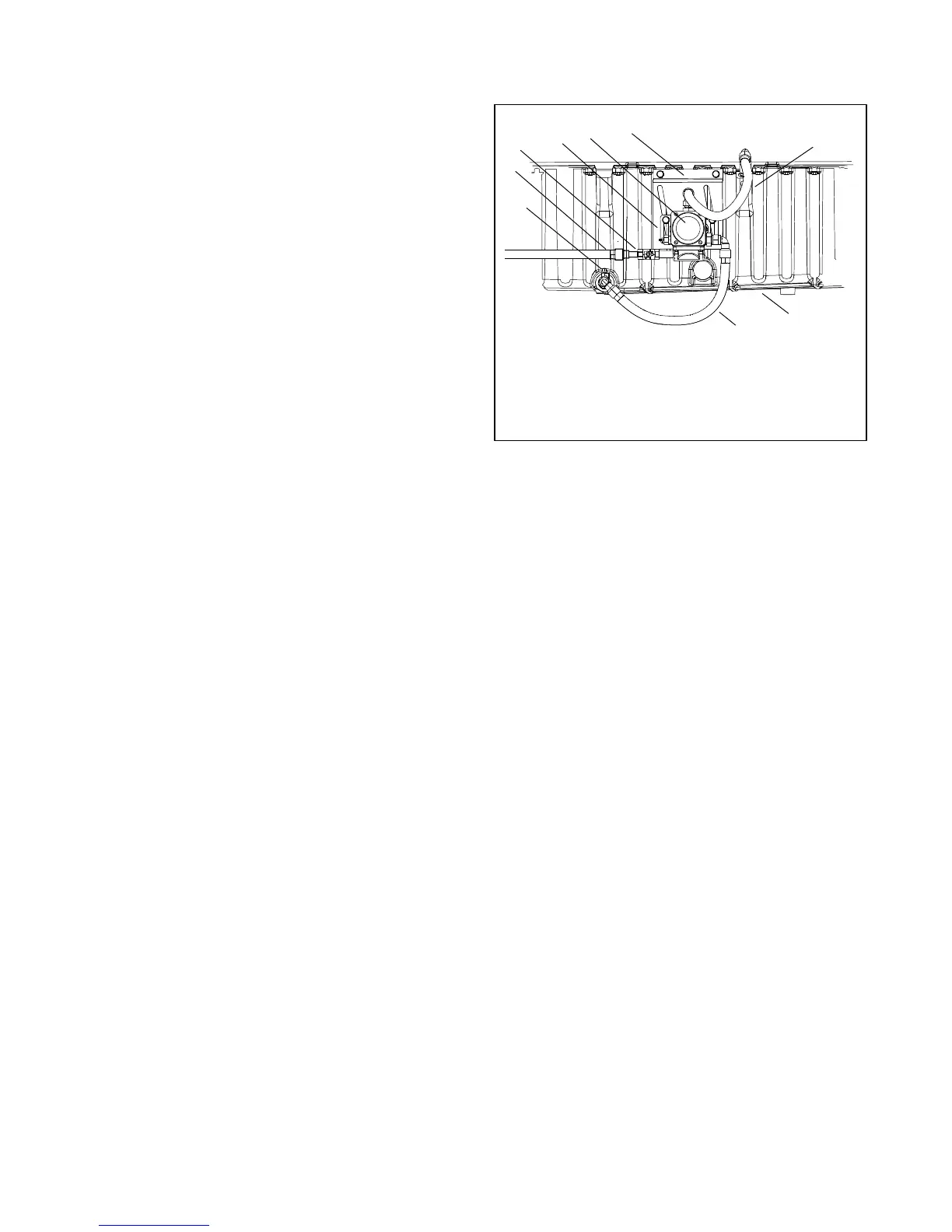

Adjusting the oil level regulator position

The oil level regulator can be adjusted by changing the

positioning of the regulator on the mounting bracket.

Use the following procedure:

Note: If the oil level regulator runs continuously, lower

the oil level regulator position approximately

10 mm (3/8 in.) on the bracket to prevent the

excess use of oil.

1. Start the engine and allow the oil level to stabilize.

2. Check the oil level on the dipstick. If the oil level is

low, adjust the regulator higher on the bracket to

allow more oil into the crankcase. If the oil level is

above the full line on the regulator, drain the excess

oil out of the crankcase and move the regulator

down on the bracket.

3. Repeat until desired running oil level is achieved.

Loading...

Loading...