.

MAINTENANCE

SERVICE PROCEDURE

7. When installing, tighten until the packing surface contacts the seal surface of the filter holder, then tighten it up

1/2 to 3/4 of a turn.

If the filter cartridge is tightened too far, the packing will be damaged and this will lead to leakage of fuel. If the

filter cartridge is too loose, fuel will also leak from the packing, so always tighten to the correct amount.

8.

After replacing filter cartridge (1), loosen air bleed plug (2).

9.

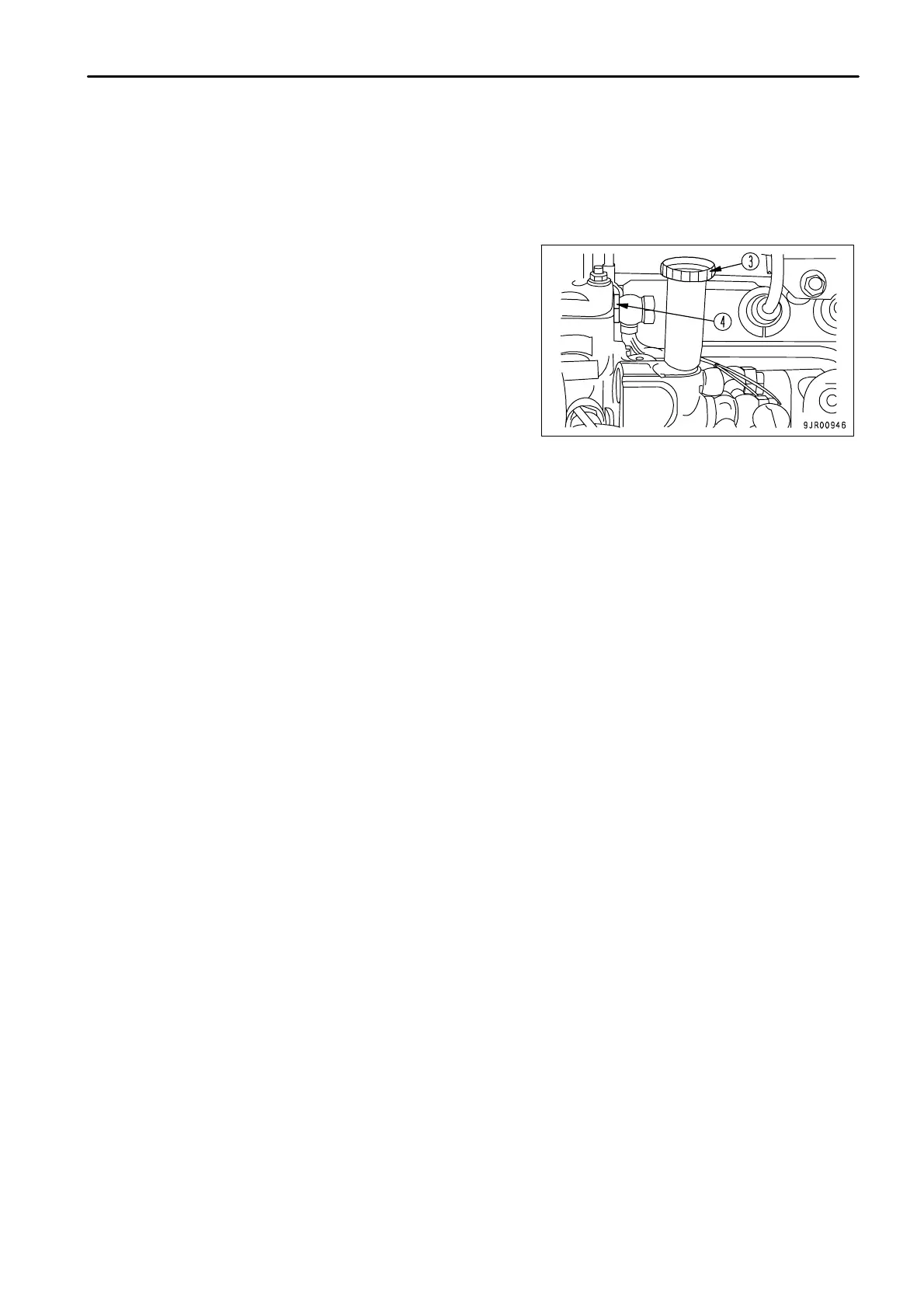

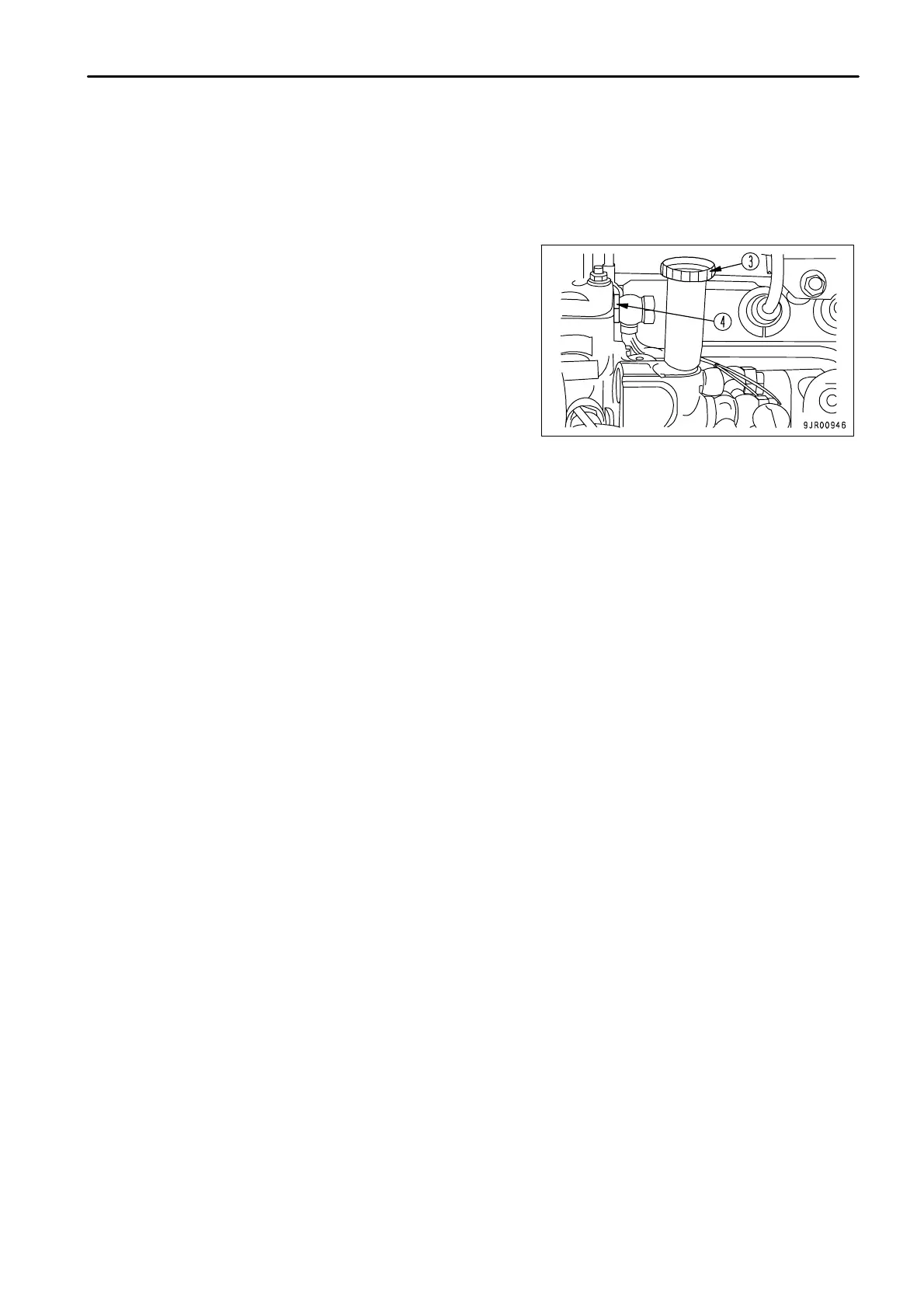

Loosen the knob of priming pump (3), then pump the knob and

check that fuel comes out from air bleed plug (2).

10.

Tighten air bleed plug (2).

Tightening torque: 7.8 to 9.8 Nm (0.8 to 1 kgm , 5.8 to 7.2 lbft)

11. Loosen air bleeder (4) of the supply pump.

12.

Pump priming pump (3) (approx. 90 to 100 times) until no more

bubbles come out with the fuel from air bleeder (4), then tighten

air bleeder (4).

Tightening torque: 4.9 to 6.9 Nm (0.5 to 0.7 kgm , 3.6 to 5.1 lbft)

13. Continue pumping until priming pump (3) becomes stiff.

14.

Push the knob of priming pump (3) in and tighten it.

15.

After replacing the filter cartridge, start the engine and check that there is no leakage of fuel from the filter seal

surface. If any leakage of fuel is found, check that the filter cartridge is tightened properly. If the fuel still leaks,

repeat Steps 1 and 2 to remove the filter cartridge, then check the packing surface for damage or embedded dirt.

If any problem is found, replace the cartridge with a new part, then repeat Steps 3 - 15 to install the new cartridge.

4 - 55

Loading...

Loading...