.

MAINTENANCE

SERVICE PROCEDURE

EVERY 4000 HOURS SERVICE

Maintenance for every 50, 100, 250, 500, 1000 and 2000 hours service should be carried out at the same time.

CHECK WATER PUMP

Check that there is no play in the pulley or any grease leakage, water leakage, or clogging of the drain hole. If any

problem is found, contact your Komatsu distributor for disassembly and repair or replacement.

CHECK VIBRATION DAMPER

Check that there is no drum-shaped deformation of the surface of the damper, and check that there are no traces

of leakage of the damper oil around the damper.

If any abnormality is found, please contact your Komatsu distributor for replacement of the parts.

CHECK FAN PULLEY AND TENSION PULLEY

Check for play of the pulley and leakage of grease. If any problem is found, please contact your Komatsu distributor.

CHECK AIR CONDITIONER COMPRESSOR, ADJUST

As special tool is required for checking and adjusting the parts, request Komatsu distributor for service.

REPLACE INJECTOR

Ask your Komatsu distributor to carry out this work.

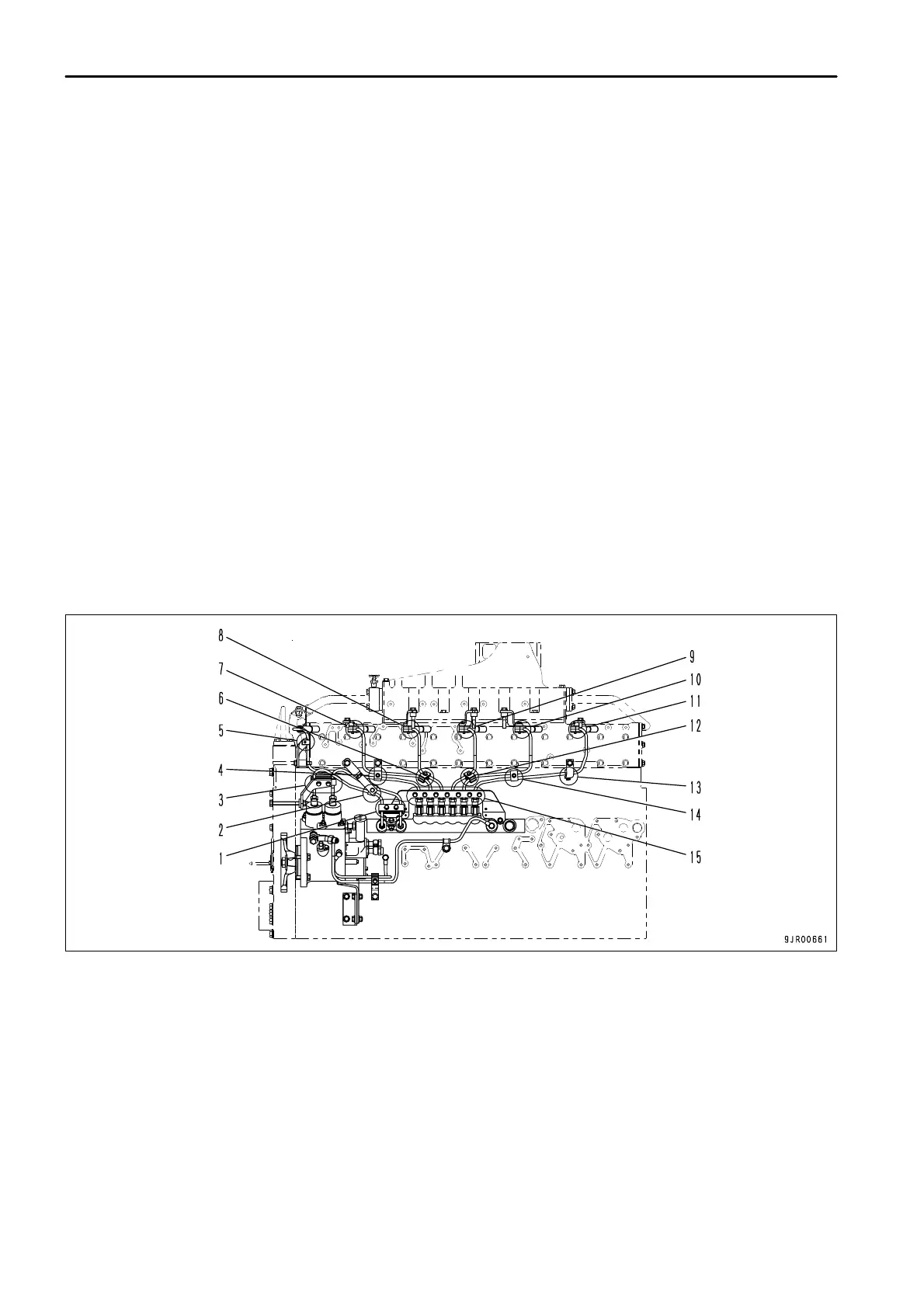

CHECKING FOR LOOSENESS OF HIGH-PRESSURE CLAMP, HARDENING OF RUBBER

Check visually and touch with your fingers to check that there are no loose bolts or hardening of rubber parts at

clamps (1) to (15). If there is any looseness or hardened rubber, contact your Komatsu distributor for replacement.

NOTICE

If the engine continues to be operated when there are loose clamps or hardened or missing rubber, the connections of the

high-pressure piping may be damaged by the friction or vibration.

Always check that the high-pressure piping clamps are fitted correctly.

4 - 68