II - 39

WSM Minor Change II Service Engineering Section

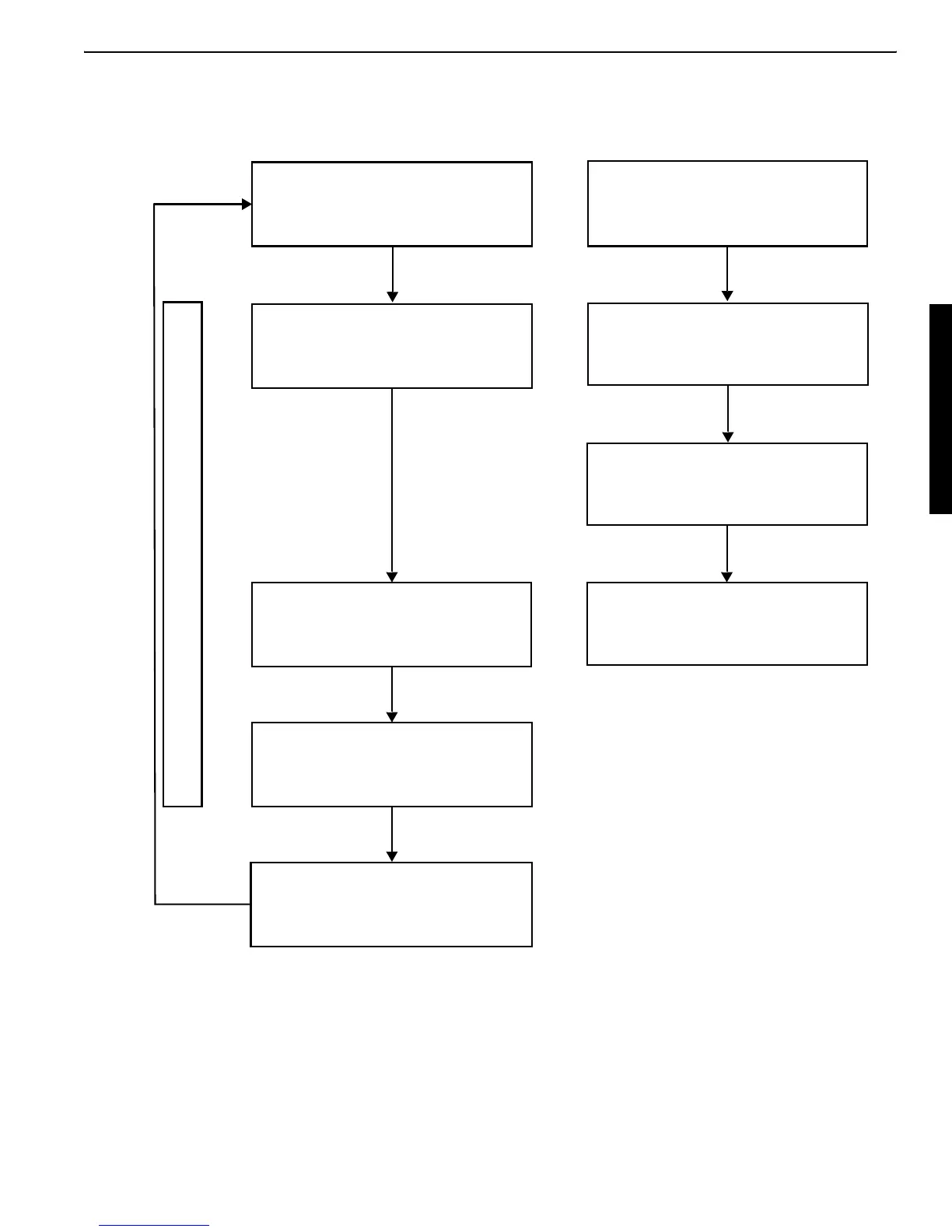

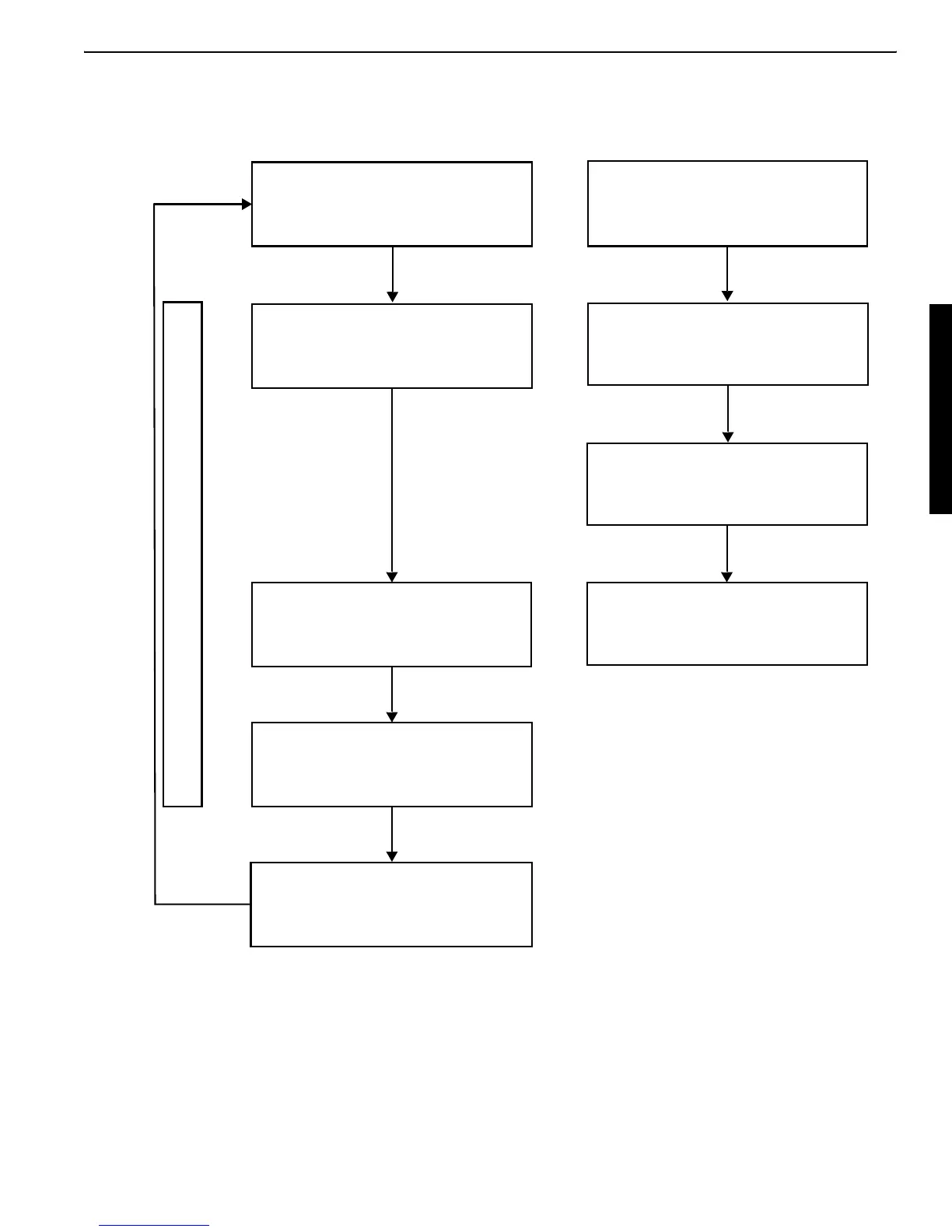

5. S/P valve initial set-up flow chart

For the right direction, enter the

knob's output voltage with the

engine at maximum rpm.

Visually make sure that the cylinder has started moving.

Controller

PWM current is

The proportional control solenoid

valve spool starts shifting.

The main control valve

spool starts shifting.

The thumb cylinder starts moving.

When the thumb cylinder starts

moving, press the service port

button on the panel.

Now the controller's PWM output cur-

rent has been set so that the thumb

cylinder starts moving at a preset

knob position (an input at maximum

rpm). This cylinder behavior occurs

at any engine speed.

Precisely speaking, controller’s out-

put current is the same at a preset

knob position.

Therefore, the solenoid force of the

S/P valve and the secondary pailot

pressure are identical.

So spool shift amount of the main

control value section is the same.

But as the main pump delivery rate

varies and so thumb cylinder’s start-

ing point varies according to the

engine speed to same extent.

Then why do the start-up setting at

max. engine speed?

For safety.

Setting complete.

Do the same for the left direction.

Enter the start-point output volt-

age in the controller.

outputted.

<Machine’s operation cycle> <Operator’s action>

Loading...

Loading...