63PERIODIC SERVICE

DAILY CHECK

For your own safety and maximum service life of the

machine, make a through daily inspection before

operating the machine to start the engine.

To avoid personal injury:

A Be sure to check and service the tractor on a

flat place with the engine shut off and the

parking brake "ON".

BWalk Around Inspection

Look around and under the tractor for such items as loose

bolts, trash build-up, oil or coolant leaks, broken or worn

parts.

BChecking and Refueling

To avoid personal injury:

A Do not smoke while refueling.

A Be sure to stop the engine before refueling.

1. Check the amount of fuel by fuel gauge.

2. When the fuel warning indicator lights up, it is time to

add fuel.

A Park the tractor at a flat ground in order to check this

indicator.

3. Use grade No.2-Diesel fuel at temperatures above

-10 (14 )

Use grade No.1-Diesel fuel at temperatures below

-10 (14 ).

A Do not permit dirt or trash to get into the fuel system.

A Be careful not to let the fuel tank become empty,

otherwise air will enter the fuel system, necessitating

bleeding before next engine start.

A Be careful not to spill during refueling. If a spill should

occur, wipe it off at once, or it may cause a fire.

A To prevent condensation (water) accumulation in the

fuel tank, fill the tank before parking overnight.

A No.2-D is a distillate fuel of lower volatility for engines

in industrial and heavy mobile service.

(SAE J313 JUN87)

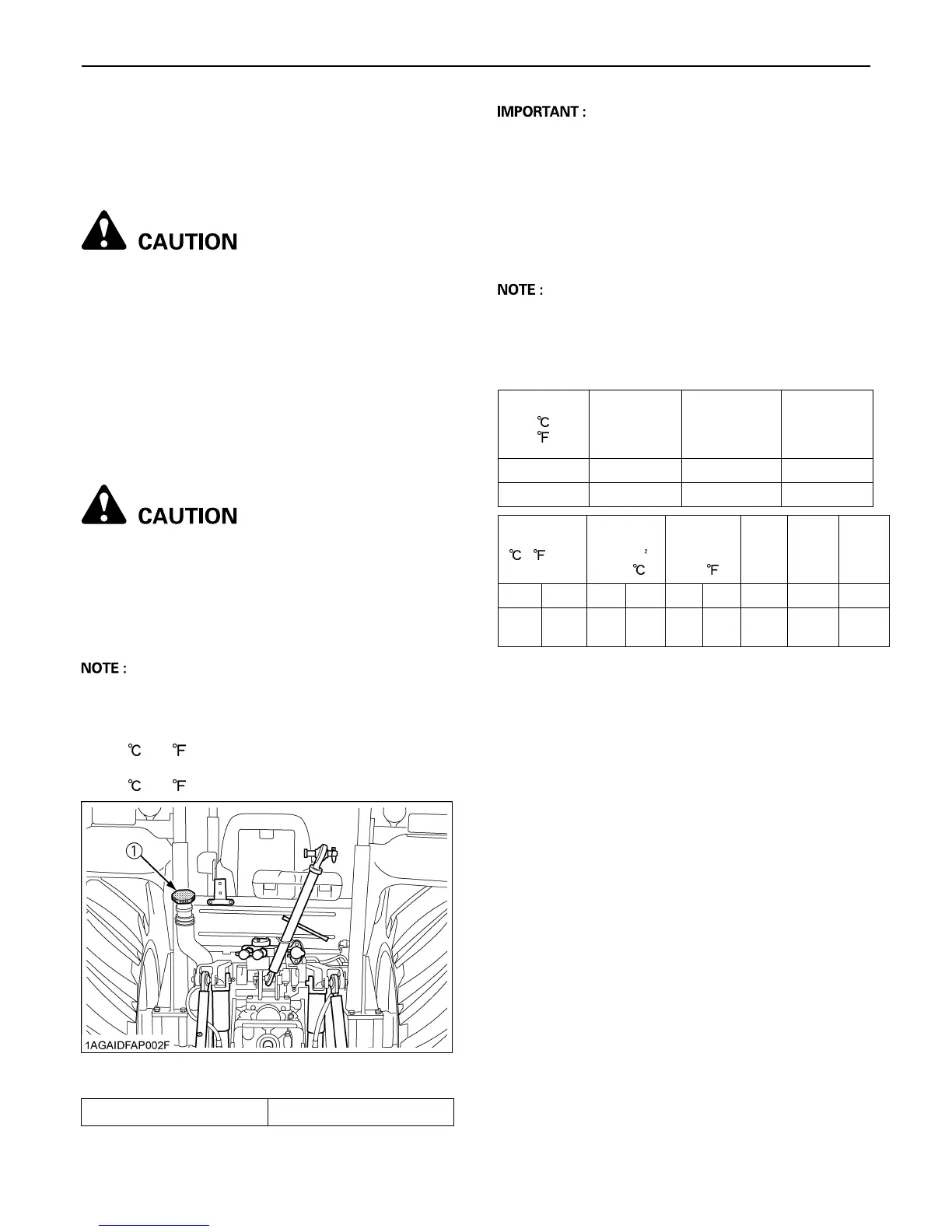

A Grade of Diesel Fuel Oil According to ASTM D975

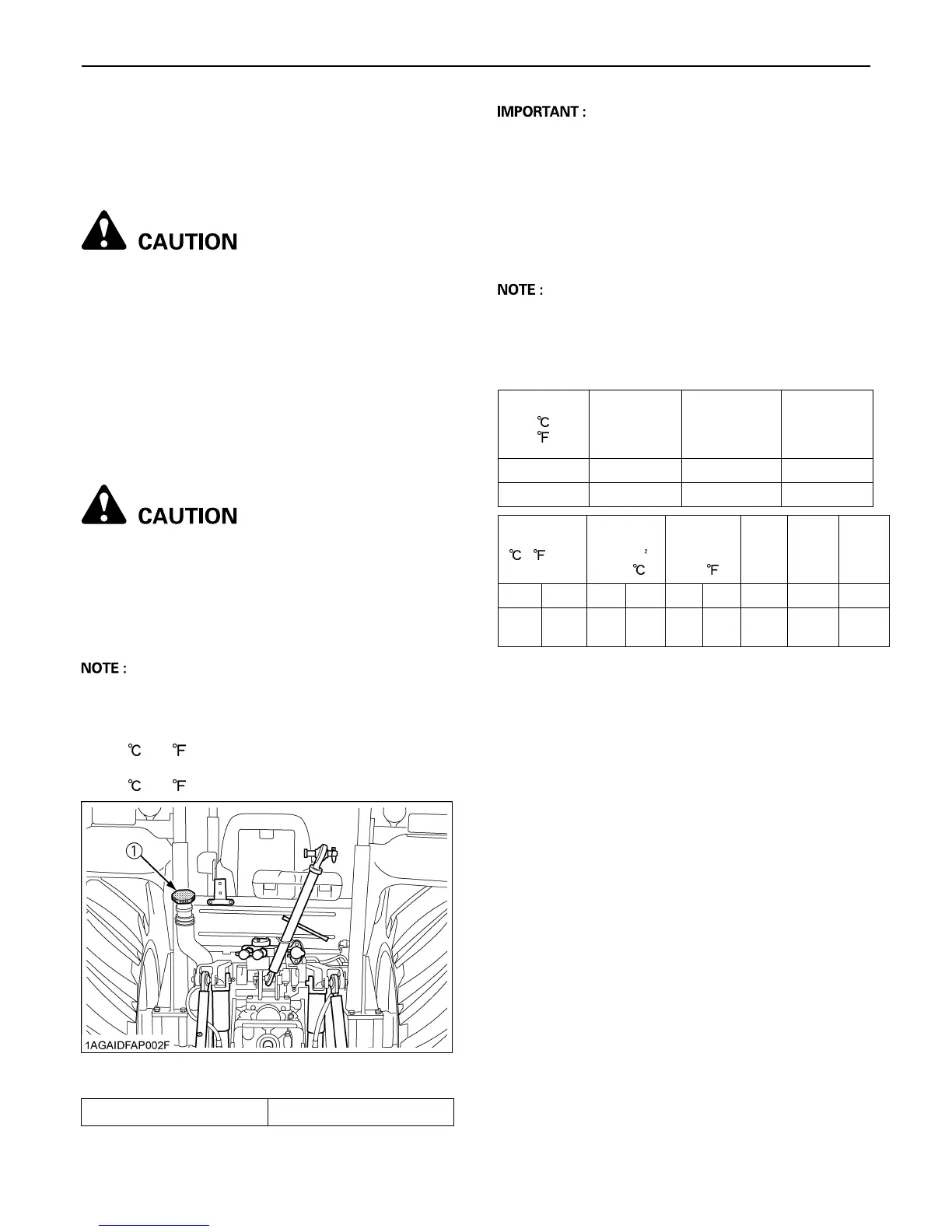

(1) Fuel tank cap

Fuel tank capacity 90 L (23.8 U.S.gals.)

Flash Point

()

Water and

Sediment,

volume

%

Carbon Residue

on,

10 percent

Residuum, %

Ash, weight

%

Min Max Max Max

52 (125) 0.05 0.35 0.01

Distillation

Temperatures,

() 90%

Point

Viscosity

Kinematic

cSt or mm /s

at 40

Viscosity

Saybolt,

SUS at

100

Sulfur,

weight

%

Copper

strip

Corro-

sion

Cetane

Num-

ber

Min Max Min Max Min Max Max Max Min

282

(540)

338

(640)

1.9 4.1 32.6 40.1 0.50 No.3 40

Loading...

Loading...