SERVICE INFORMATION

GENERAL INSTRUCTIONS

• Check the ignition system according to the sequence specified in the Troubleshooting. (

1-28)

• The ignition system adopts CDI unit and the ignition timing cannot be adjusted.

• If the timing is incorrect, inspect the CDI unit and A.C. generator and replace any faulty parts.

Inspect the CDI unit with a CDI tester

• Loose connector and poor wire connection are the main causes of faulty ignition system. Check

each connector before operation.

• Use of spark plug with improper heat range is the main cause of poor engine performance.

• The inspections in this section are focused on maximum voltage. The inspection of ignition coil

resistance is also described in this section.

• Inspect the ignition switch according to the continuity table specified in page

20-3.

• Inspect the spark plug referring to Section 3.

• Remove the A.C. generator and pulser coil referring to Section 10.

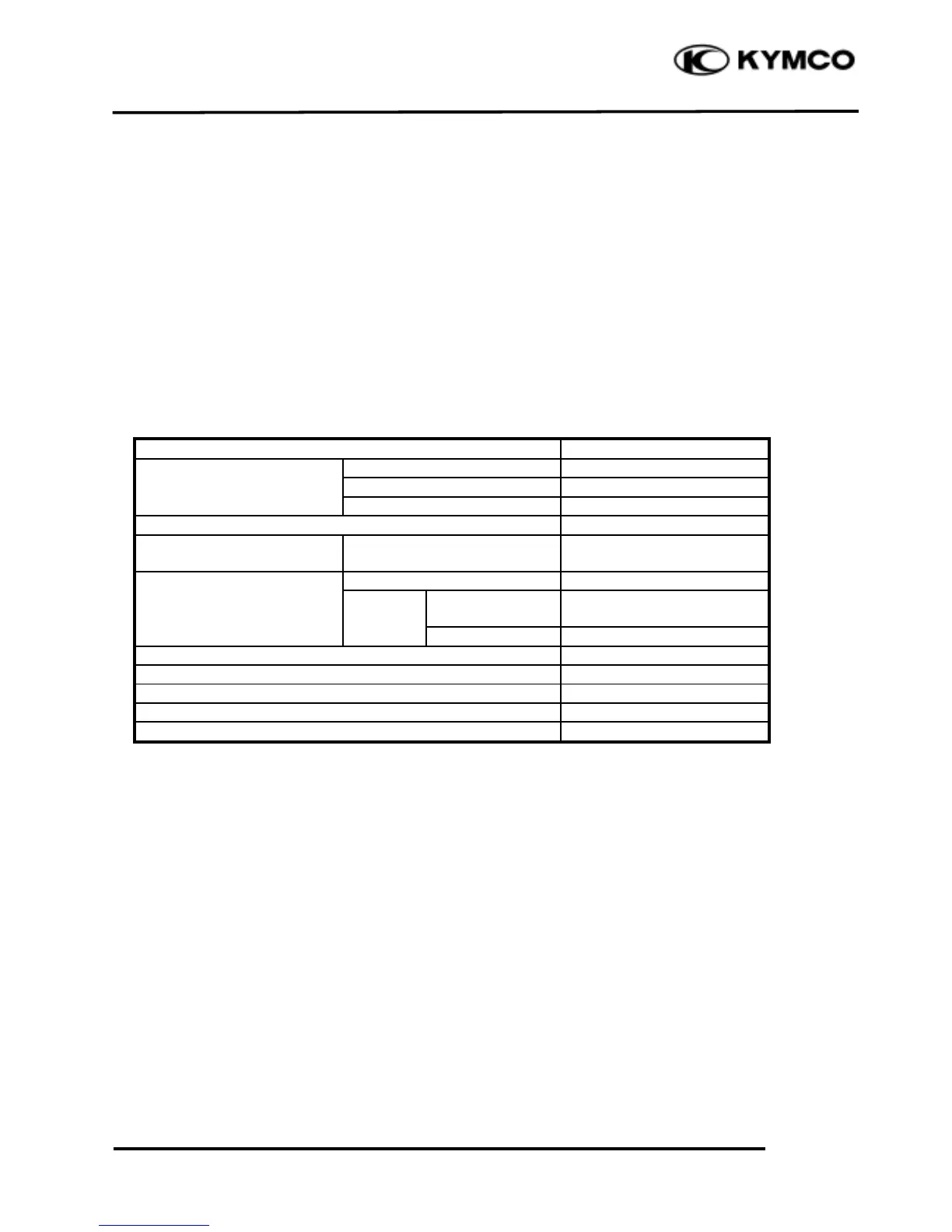

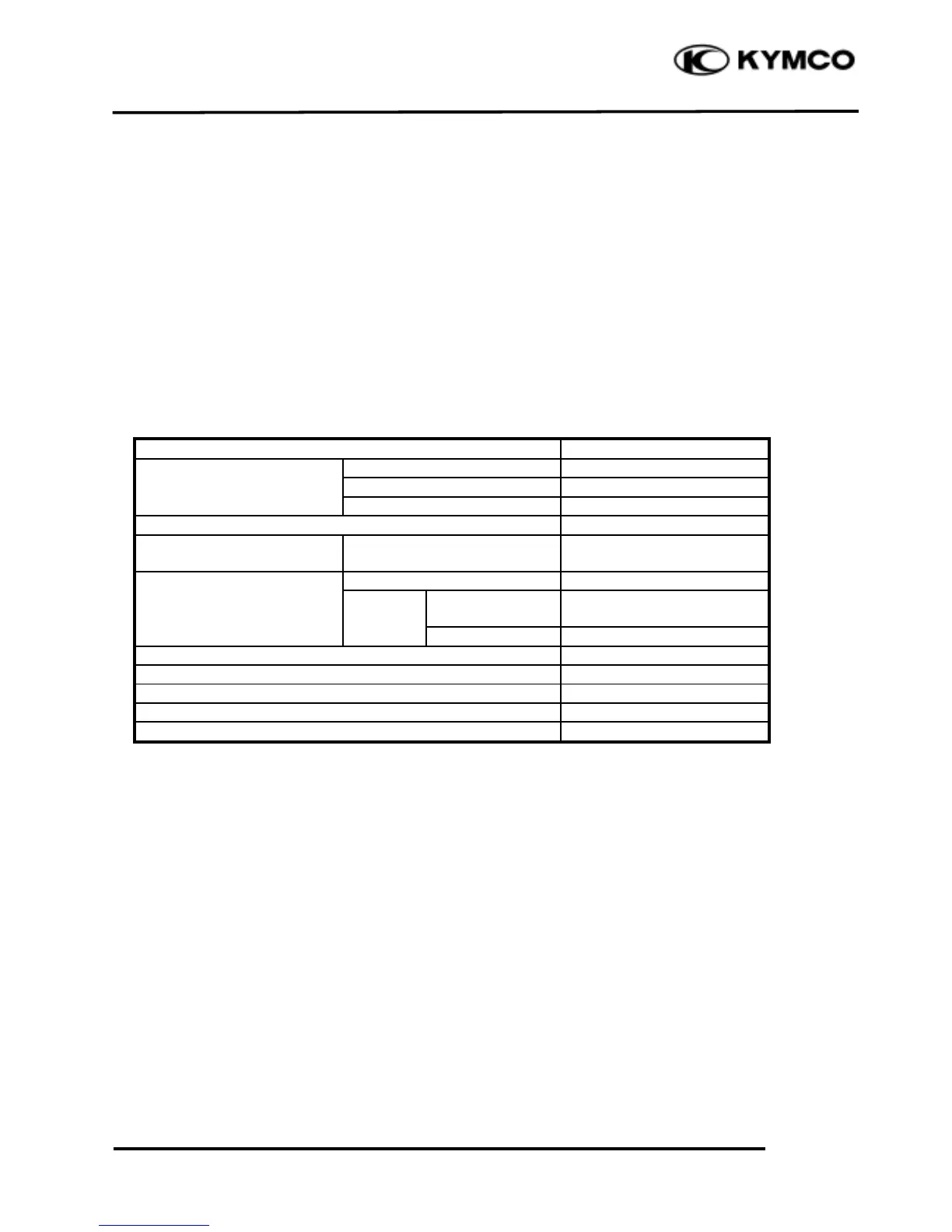

SPECIFICATIONS

Ignition coil resistance

(20℃ )

Pulser coil resistance (20℃ )

Exciter coil resistance (20℃ )

Ignition coil primary side max. voltage

Exciter coil max. voltage

TESTING INSTRUMENT

Electric tester

TROUBLESHOOTING

No spark at plug Engine starts but turns poorly

• Faulty spark plug • Ignition primary circuit

• Poorly connected, broken or shorted wire —Faulty ignition coil

• Faulty ignition switch —Poorly connected wire or connector

• Faulty ignition coil —Poorly contacted ignition switch

• Faulty CDI unit • Ignition secondary circuit

• Faulty A.C. generator —Faulty ignition coil

—Faulty spark plug

—Faulty high-tension wire

—Poorly insulated plug cap

• Improper ignition timing

—Faulty A.C. generator

—Stator not installed properly

—Faulty CDI unit

Loading...

Loading...