6. CYLINDER HEAD/VALVES

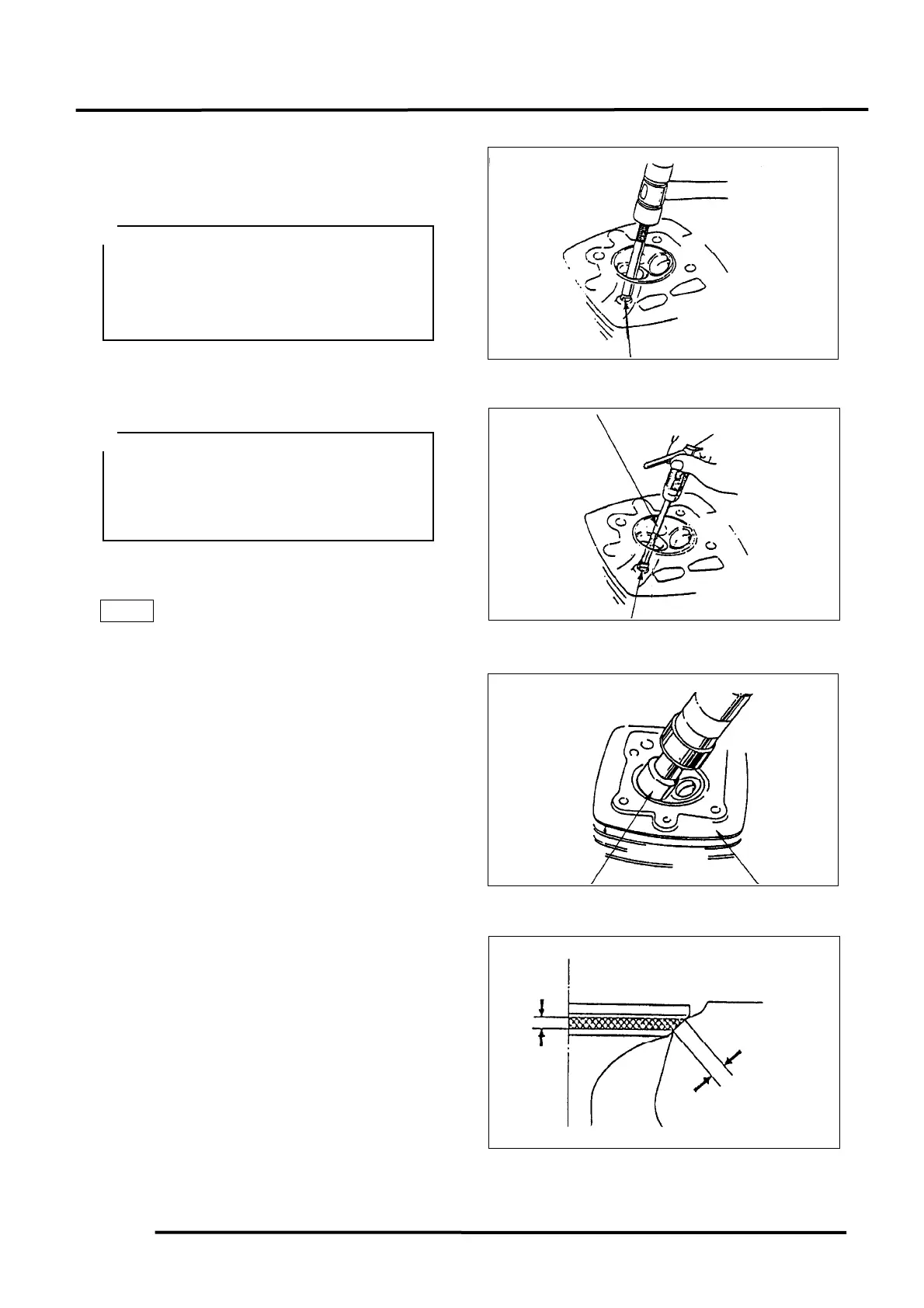

Apply engine oil to new O-rings and install

them to new valve guides.

Then, drive in new valve guides.

Ream the new valve guides with a valve

guide reamer.

Clean the cylinder head and remove any

metal particles.

Valve Guide Reamer

VALVE SEAT INSPECTION &

REFACING

VALVE SEAT INSPECTION

Remove carbon deposits from the

combustion chamber and valves.

Apply emery to each valve and valve seat

contact face.

Lap each valve using a hand lapper.

Remove the valve and inspect the valve face.

If the valve face is rough, worn unevenly, or

contacts the seat improperly, the valve must

be replaced.

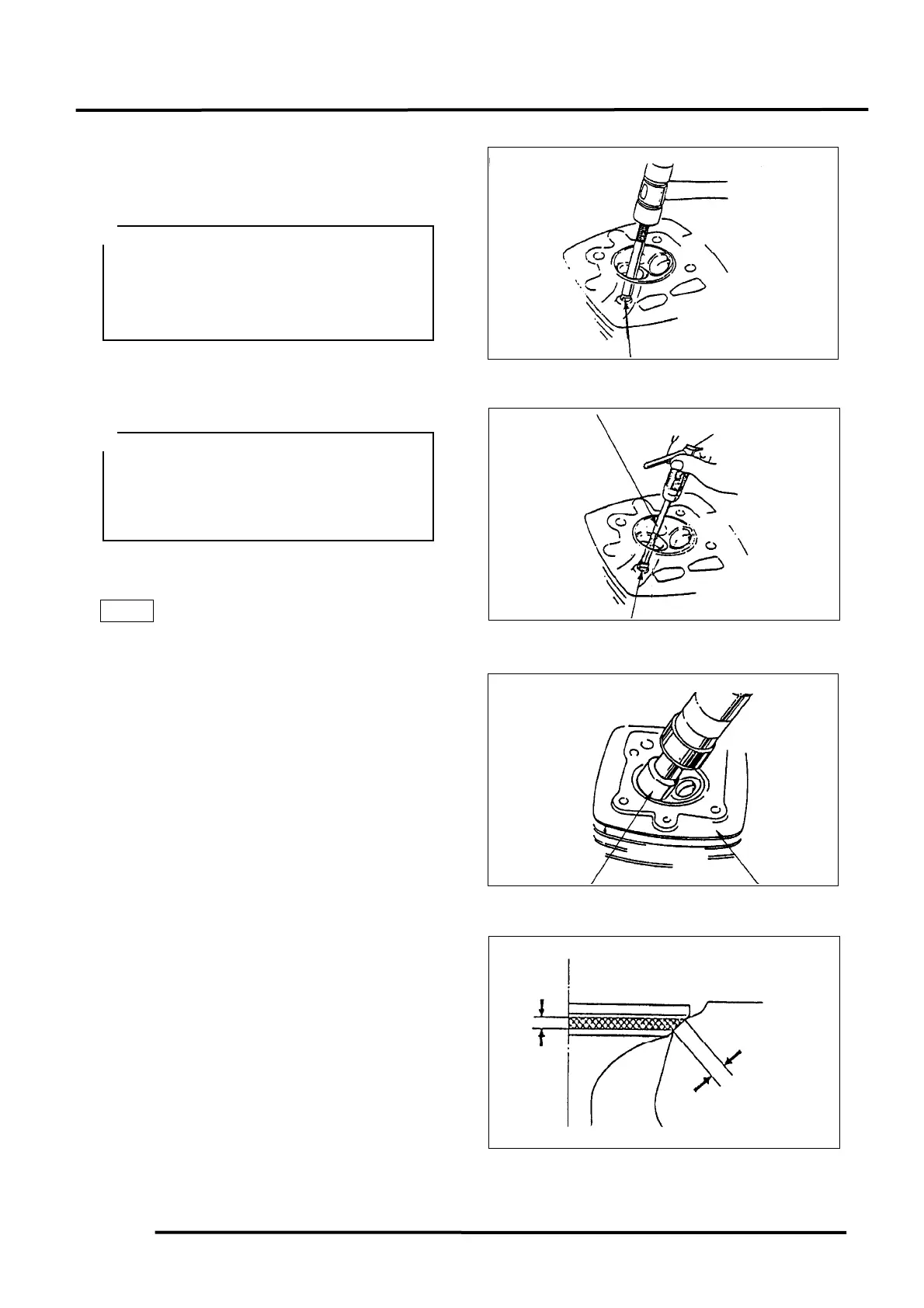

Inspect the valve seat width.

Service Limit: 1.2~1.5mm replace if over

If the seat is too wide or too narrow or has

low spots, the seat must be ground using a

valve seat cutter.

Be careful not to damage the cylinder

head mating surface.

• Check for damage after driving in the

new valve guides.

• The new valve guides must have

Use cutting oil on the reamer during

this operation.

• Rotate the reamer clockwise and do not

insert or remove it straight when it is

stopped.

Loading...

Loading...