6. CYLINDER HEAD/VALVES

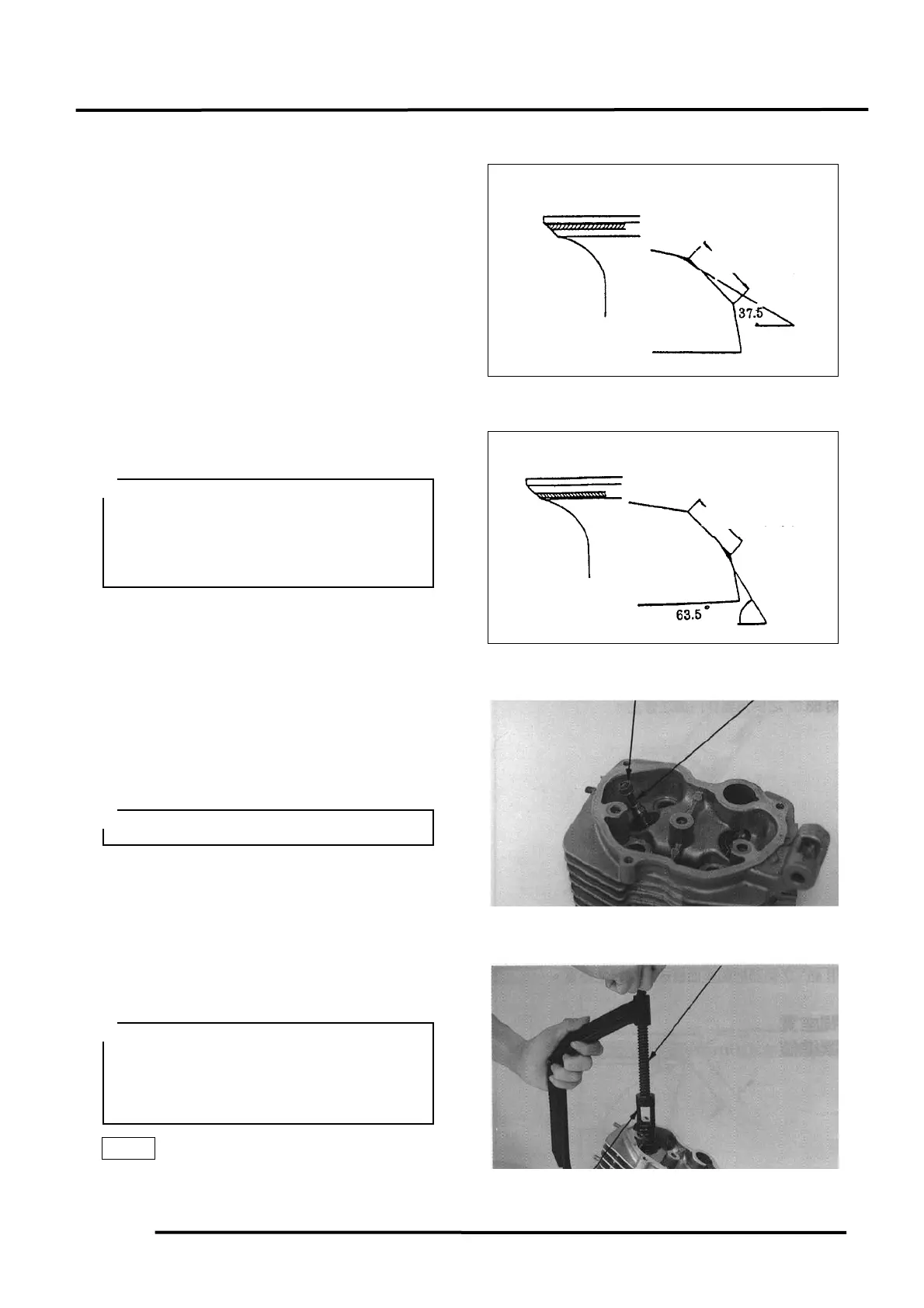

Inspect the valve seat contact area.

If the contact area is too high on the valve,

the seat must be lowered using a 37.5° cutter.

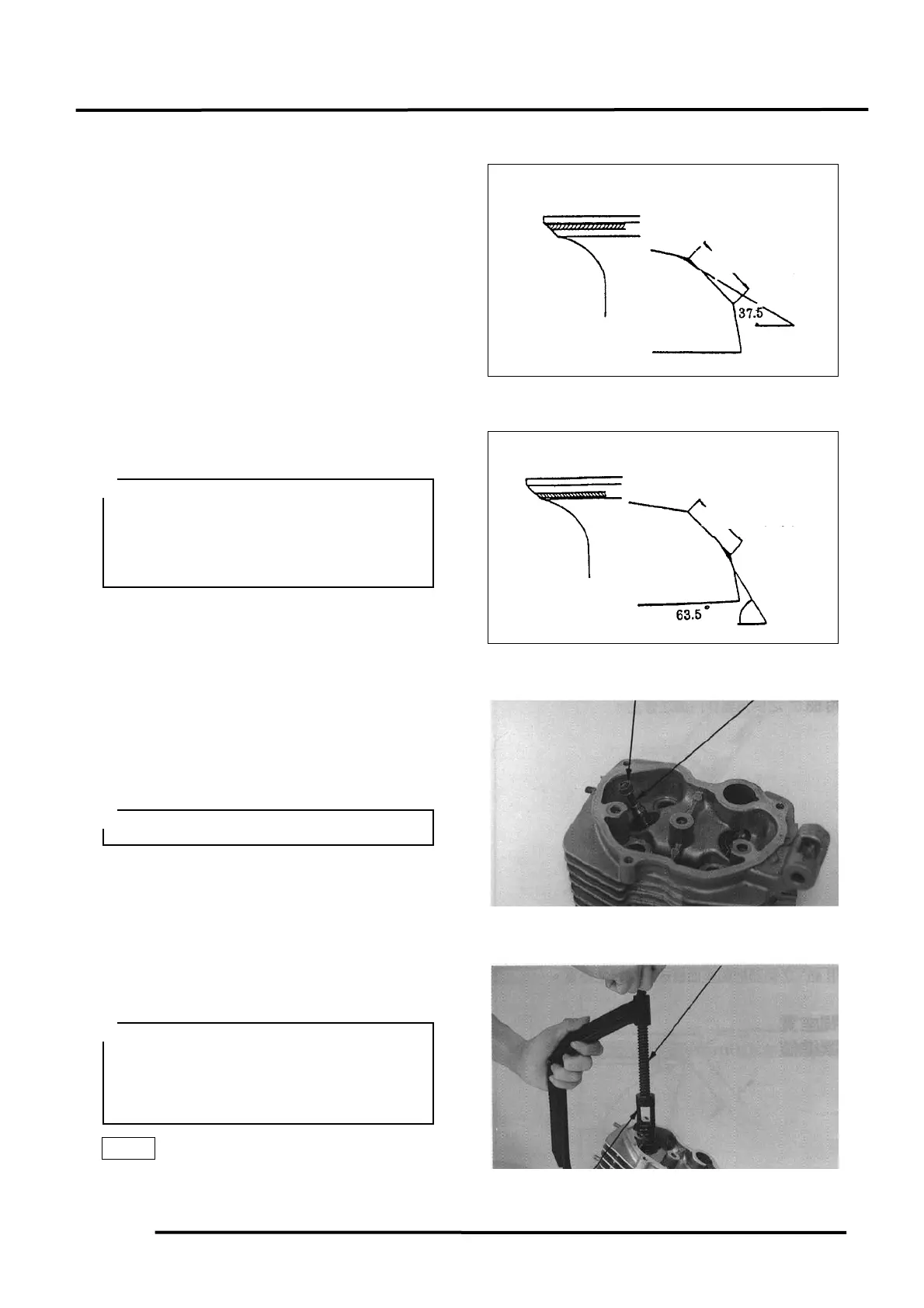

If the contact area is too low on the valve, the

seat must be raised using a 63.5° cutter.

Refinish the seat to specifications using a 45°

seat cutter.

After cutting the seat, apply emery to each

valve contact face and lap the valve using a

lapper.

After lapping, wash all residuals off the

cylinder head and valves.

After refacing and lapping, apply red lead to

the 45° valve seat to make sure that the

center of the valve contact face is even.

CYLINDER HEAD ASSEMBLY

Lubricate each valve stem with engine oil

and insert the valves into the valve guides.

Apply engine oil to the valve stem seals and

install them into the valve guides.

Install the valve spring seats, washers, inner

and outer springs, and retainers.

Compress the valve springs using the valve

spring compressor, then install the valve

cotters.

Valve Spring Compressor

Valve Spring Compressor Attachment

Be sure to install new valve stem seals.

When lapping, use a light pressure and

avoid damaging the valve seat due to

forcedly lapping.

• Use care not to allow emery powder to

enter the valve stem and guide.

Use the valve spring compressor to

compress the springs and do not

damage the cylinder head surface.

• Install the cotters with the pointed ends

facing down.

Valve Spring Compressor Attachment

Loading...

Loading...